Double-Shaft Biomass Shredder

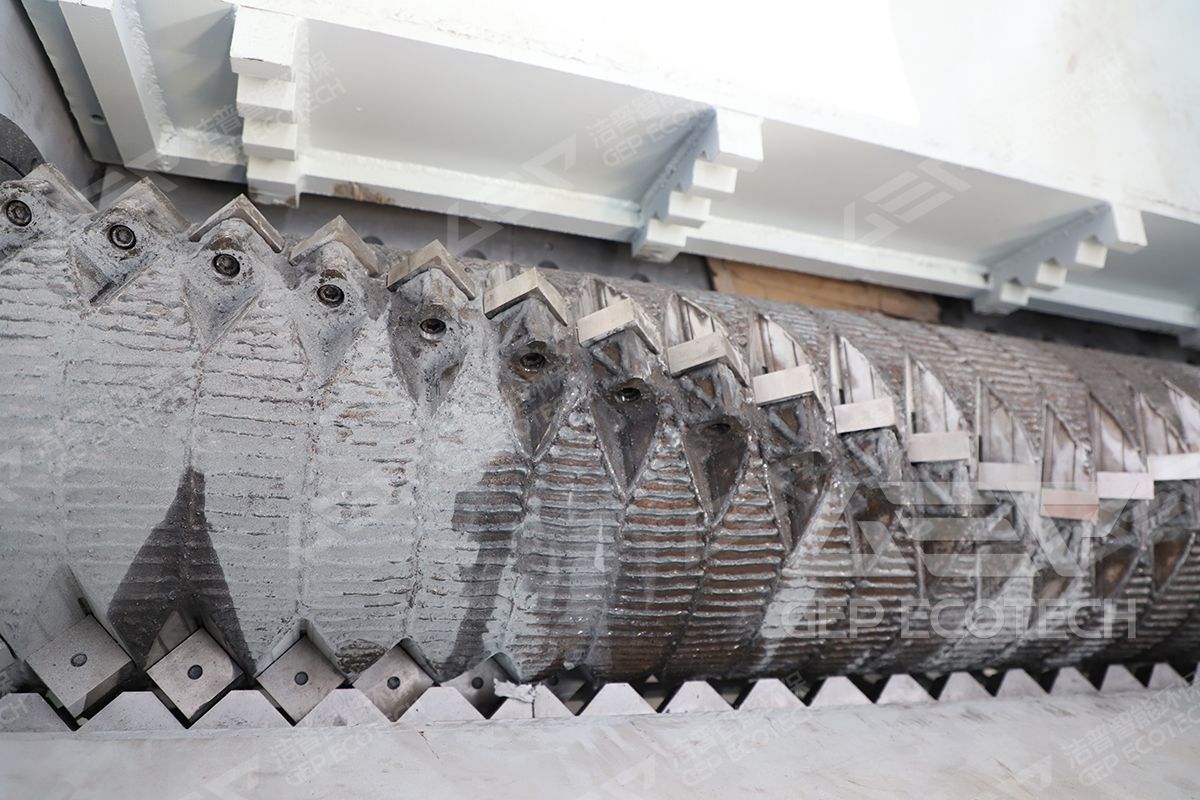

ProductThe GDB series double-shaft shredder is specially designed to handle waste from municipal green waste, rootstocks, untreated waste wood, straw or fruit shells of crops, etc. It can quickly shred biomass materials into small pieces. GEP Ecotech's double-shaft shredder has high output and reliable performance, widely used in biomass cogeneration power stations.

GDI Series Shredder is a multi-purpose dual-shaft shredder for reducing industrial and commercial wastes. It shreds various materials into optimum shapes and sizes for recycling, incineration, or landfill. GDI has unimaginable stability and is always reliable, which makes it possible to cope with the demand for waste disposal under the harshest working conditions.

Single Rotor Fine Shredder

ProductThe GSS series single rotor shredder is suitable for processing a wide range of materials to a small and uniform size, with a maximum capacity of around 1 - 20 tons per hour and a discharge size of 30 to 120 mm, depending on the model of the machine, the type of material, the size of the screen and the field of application.

Behind the prosperity of the local leather processing industry, waste materials such as waste leather and waste textiles have caused serious environmental pollution and become a focus of public attention. As a result, the government has consolidated and shut down hundreds of related enterprises, leading to a significant decline in annual output value. In order to solve the problem of industrial solid waste restricting economic development, the local government has launched a recycling project, striving for a win-win situation between economy and environmental protection. In this project, industrial solid waste is transported to the storage pit by garbage collection trucks, and then shredded to a size of 150-200mm by a double shaft shredder, and mixed with sludge for co-firing. Since the project started, the equipment has been in good condition and the size of the shredded materials meets the standard. This effectively alleviates the environmental problems caused by the leather processing industry and explores

Compared to coal powder, waste spinning has the advantages of high volatile matter, low ash content, low moisture content, and considerable calorific value (average around 4,300 kcal), and has good potential as a substitute fuel. GEP ECOTECH has tailored this fuel pretreatment solution for customers, covering processes such as three-stage double shaft shredder shredding, magnetic separator for iron removal, and baling machine for compression. In this scheme, specific design adjustments are made to the cutters of each stage of the double shaft shredder to gradually reduce the discharge size, ultimately meeting the size requirements for fuel entering the boiler, effectively improving the applicability and stability of textile waste as an alternative fuel in the cement production process. The customer stated that the production line ensures stable and high-quality fuel supply, meeting their demand for high-quality fuel.

All equipment of the project (double-shaft shredder, magnetic separator, chain plate conveyor, belt conveyor, intelligent control system and dust removal system) are purchased from GEP ECOTECH. The main treatment materials are bulky waste, such as sofas, mattresses, wooden furniture, etc. that are no longer used in the life of residents. After mechanical shredding, magnetic separation, manual disassembly and other treatments, bulky waste will be removed from high priced materials like metals, and teh rest materials will be sent to waste incineration plant for incineration. The customer said that since the introduction of the intelligent bulky waste shredding process from GEP ECOTECH, it has completely solved the problems of local bulky waste, such as disorderly stacking and difficult disposal, which has improved the local waste sorting classification treatment level.

There are various industrial copper wire shredder machines available for sale, which can be used to process copper wires and cables into smaller pieces for further recycling or refining. Here are some of the options available:Waste copper wireDual Shaft Shredders: These are heavy-duty machines that are designed to process large volumes of copper wires and cables. They feature two rotating shafts with sharp blades that shred the materials into smaller pieces.Single Shaft Shredders: These are similar to dual shaft shredders, but feature only one rotating shaft with blades. They are designed for medium-sized material processing and are commonly used for copper wires finer shredding.Granulators: These machines use a combination of shredding and granulating to process copper wires and cables into smaller pieces. The copper pieces are then sorted and separated by size or density.When purchasing an industrial copper wire shredder machine, it is important to consider the specific needs of the recycling operation,

Fabric shredder machines in garment industry is also called garment shredder, it is a shredder used for shredding waste clothes, blankets, shoes and other textiles. The garment shredder is usually composed of a shredder main body and a bracket. The blades are of anti-winding design. GEP ECOTECH double single shaft shredder and double shaft shredder are suitable for different kinds of garment shredding purposes.Why we need fabric shredder machines in garment industry?Fabric shredder is a very useful equipment in garment recycling. Some people don't understand the value of a fabric shredder, and think that shredding old clothes with a shredder seems to be a waste. Because shredding can destroy the clothes and tear them into pieces. In fact, this is a misunderstanding. Fabric shredders are very important in the garment recycling industry.As we all know, a very critical step in garment recycling is sorting. Garment can be further divided into several groups for different recycling purposes. Some garments can be

The stationary biomass shredder machine can crush the biomass into lumps less than 100mm, making it easy to store, transport and supply on a large scale. GEP ECOTECH, as a professional biomass shredder manufacturer, has many successful project cases around the world, let us know about this stationary biomass shredder machine factory briefly.GEP ECOTECH stationary biomass shredder machine factoryintroduction:GEP ECOTECH stationary biomass shredder machine factory has 1 meter, 2 meter, 3 meter, 6 meter, 11 meter CNC machining center, CNC lathe, precision milling machine, precision drilling machine, precision grinder, laser cutting machine and other complete machining equipment, of which the main machining There are more than 100 sets (sets) of equipment, which can complete the production and processing of all parts, and the advanced heat treatment technology provides a guarantee for the high-precision processing and mass production of the company's stationary biomass shredder machine!GEP ECOTECH popular

Metal shredders are essential machines in the recycling and waste management industries, designed to process various types of materials, including metals. This article will explore the specifications and features of three common types of metal shredders: single-shaft shredders, dual-shaft shredders, and hammer shredders.Single-Shaft ShreddersOverview: Single-shaft shredders utilize a single rotating shaft equipped with sharp blades to cut materials into smaller pieces. They are ideal for fine shredding a variety of materials, including metals, plastics, and wood.Specifications of GEP's Single-Shaft Shredders:ModelCapacity (t/h)Output size (mm)Dimension (mm)GSE3121-530-1203000×2000×3000GSE3153-103600×2000×3000GSE3206-183800×2000×3000GSE33010-255600×2200×3300Dual-Shaft ShreddersOverview: Dual-shaft shredders consist of two counter-rotating shafts, making them highly efficient for shredding tough materials like metal drums and heavy metal parts.Specifications of GEP's Dual-Shaft Shredders:ModelCapacity (t/h)

PVC shredders play a crucial role in recycling and waste management by breaking down PVC materials into smaller, manageable pieces for further processing. These shredders come in two main configurations: single shaft and double shaft. Both types serve different purposes depending on the material’s nature and the desired output.Single Shaft PVC ShredderA single shaft shredder has a rotor with sharp cutting blades and a stationary screen, through which the shredded material passes once it reaches the desired size. It is best suited for processing lighter, less dense PVC materials.Key Features:Precision Shredding: Single shaft shredders offer finer control over the particle size, making them ideal for applications where uniform output is essential.Hydraulic Ram: The material is pushed against the rotor using a hydraulic ram, ensuring steady feeding and preventing clogging.Lower Capacity: These shredders are typically used in operations with lower volume requirements.Best Applications:Light PVC pipes, films, and

The main purpose of waste plastic shredder machine is shredding any type of polymer waste: polymer films, profiles, plastic pipes, sprues, castings, PET bottles, waste from injection and thermoforming production. These shredders have different capacities and shredding sizes. For shredding plastics, a two-stage scheme is usually used, with primary shredding in a shredder followed by regrinding in plastics shredders. Since polymers are characterized by increased strength and abrasiveness, plastic shredders are manufactured with a significant margin of strength and wear resistance.For the processing of plastics, the GEP Ecotech offers shredders of several models at once; equipment of the GSS, GSD, GDI series is produced for the specific needs of industrial enterprises. Shredders of the GDI series are used to process all types of plastics, in particular hard and resilient materials. These machines shred industrial plastic waste, pipes, car parts, blow moldings - bottles, cans, barrels. GSX is a new generation of

What is industrial waste?Industrial waste is defined as waste generated by manufacturing or industrial processes. The types of industrial waste generated include cafeteria garbage, dirt and gravel, masonry and concrete, scrap metals, trash, oil, solvents, chemicals, weed grass and trees, wood and scrap lumber, and similar wastes. Everyday, huge amount of industrial wastes are produced, it damage our living environment and take large land, so a suitable way to dispose industrial waste is important.What can industrial waste shredder do?The industrial shredders are useful machines for the volume reduction, usually the industrial wastes are with big volume and take large land, no matter waste leather, waste tire, waste wood, waste textile, any waste produced during industry production, using a industrial shredder can shred the waste into small pieces, on one hand, the waste volume is reduced, it is much easy for transportation; on the other hand, the recycled material in the industrial waste can be recycled, and

GD5, a small shredder developed by GEP ECOTECH, is often used to crush beverage cans, iron filings, copper wires, scrap parts and other metals. The price of small metal shredder machine will vary with different configurations, and the average price is around 50,000 US dollars. Let's take a brief look at this device.The parameters of GD5 shredderCapacity: 2-8 tons/hourOutput: 30-200mmPower: 10-45kwSize: 2100×1000×1900 (can be customized according to the actual situation)Advantages: wear-resistant cutter, multi-combination seal, anti-winding function, automatic shutdown mechanisms, emergency stop buttons, or overload protectionFactors affecting the price of GD5 shredderThe price of a GD5 shredder can be influenced by several factors. Here are some key factors that affect the price:Motor Power: The power and efficiency of the motor used in the shredder can affect its price. Shredders with higher horsepower or more advanced motor technology tend to be more expensive.Additional Features and Customization Options

Industrial shredder machine for hard plastics uses the working principle of shearing, tearing and squeezing between knives to crush hard plastics of different sizes into small pieces of a certain size, saving storage and transportation space, and facilitating the recycling and processing of waste plastic materials into a variety of recycled products.GEP ECOTECH industrial shredder machine for hard plastics adopts imported crushing tools, which have corrosion resistance and impact resistance. At the same time, the bottom is equipped with a screen to make the output of less than 50mm at a time. We design crushing equipment and systems with different knife shapes, different torques, and different processes according to the proportion of various hard plastic wastes.Because plastic waste is difficult to degrade, landfill or incineration will cause "white pollution", which seriously harms water quality, soil, and atmospheric environment. Therefore, crushing and recycling is a good way to reduce the use of hard

Industrial waste plastic refers to the waste plastic products after industrial production. At present, our government strongly supports various places to do a good job in waste separation and recycling projects, while waste plastic is a common waste in our daily life, so its available line is very good, but also easy to recycle. Therefore, more and more people have started to engage in this industry.How can our recycled industrial plastic waste be turned into treasure?First we must know that the recycled plastic waste is different in size. So it is difficult to achieve the unified recycling, there is a key step. That is to break the material and then use it.What equipment is needed to shred the industrial plastic waste?Of course it is the single-shaft fine shredder produced by our company GEP ECOTECH. The shredder is used to shred, shear and squeeze the material to a smaller size by using the interaction between the moving knife blade and the fixed knife, and controlling the size of the discharge through the

What is hospital waste?Hospital waste is contaminated waste produced by hospitals that have come into contact with patients' blood, flesh, etc. Such as used cotton balls, gauze, adhesive tape, waste water, disposable medical instruments, post-operative discards, expired medicines, etc. According to the national health department's medical test report, medical waste is characterised by spatial pollution, acute infection and latent pollution, and its viruses and germs are dozens, hundreds or even thousands of times more harmful than ordinary household waste. If not handled properly, it will cause serious pollution to the environment and may also become a source of epidemics.Current status of hospital waste disposalSince the 1950s, the treatment of medical waste has attracted extensive attention from all over the world. Scholars at home and abroad have made increasingly rich research on medical waste treatment technology and have achieved certain research results. On this basis, through a comprehensive

The development trend of environmental protection market is becoming stronger and stronger. Domestic waste has become a huge resource, which has attracted many investors to join the solid waste resource regeneration industry. Therefore, it is necessary to select appropriate waste shredder equipment. This paper introduces several common types of waste shredders. The primary shredders which mainly used for the first shredding of the MSW or industrial waste has became the very important equipment in a solid waste disposal production line. How much is a primary shredder is the the question often be asked by customers, today let us talk about it!The different configuration and materials will affect the price sharply, the GC primary shredder produced by GEP ECOTECH is one of the leading products in this industry.Advantages of GC series primary shredder:High-strength shaftSpecial cutter designImported hydraulic motor direct driveAutomatic lubrication systemGI intelligent systemAll of above advantages created the