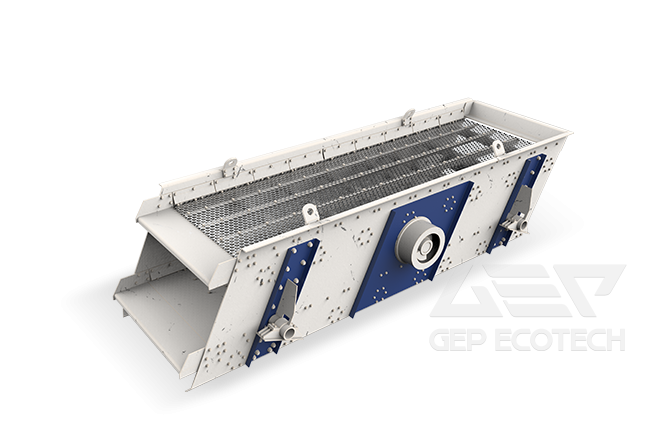

| Model | Feeding size(mm) | Capacity(t/h) | Power(kW) | Weight(t) | Dimension(mm) |

| 2GESY1237 | ≤100 | 5-60 | 11 | 3.1 | 4570×1900×1210 |

| 3GESY1237 | 11 | 3.4 | 4730×1900×1650 | ||

| 2GESY1548 | 11-90 | 15 | 5.6 | 5750×2180×1195 | |

| 3GESY1548 | 15 | 6.4 | 5910×2180×1650 | ||

| 4GESY1548 | 18.5 | 6.7 | 6070×2180×2085 | ||

| 2GESY1848 | 15-100 | 18.5 | 6.65 | 5742×2542×1195 | |

| 3GESY1848 | 18.5 | 6.95 | 5908×2542×1650 | ||

| 4GESY1848 | 18.5 | 7.25 | 6080×2550×2105 | ||

| 2GESY1860 | 25-130 | 22 | 7.52 | 7140×2630×2309 | |

| 3GESY1860 | 22 | 7.72 | 7140×2630×2409 | ||

| 4GESY1860 | 22 | 7.98 | 7140×2630×2550 | ||

| 2GESY2160 | 35-200 | 30 | 10.2 | 7157×2980×1680 | |

| 3GESY2160 | 30 | 10.5 | 7156×2980×1780 | ||

| 4GESY2160 | 30 | 10.8 | 7330×2980×2240 | ||

| 2GESY2460 | 50-260 | 30 | 10.5 | 6989×3280×1320 | |

| 3GESY2460 | 30 | 10.8 | 7175×3280×1828 | ||

| 4GESY2460 | 37 | 11.1 | 7375×3280×2240 |

Note: Technical specifications may change without notice due to ongoing technological advancements.