Waste Tire Shredding & Recycling System

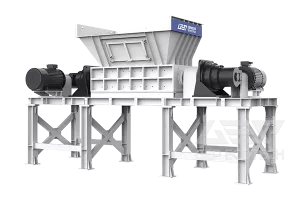

- Small-Scale Solution

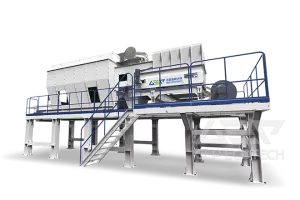

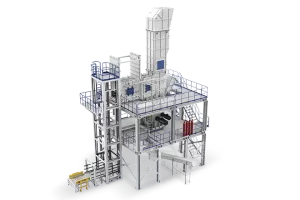

- Medium and large Solution

- Cost-effective, specially developed double-shaft shredder, only one machine can shred the entire tire to the ideal size.

- Flexible configuration, can be equipped with different equipment according to the final application and production requirements.

- Low initial investment cost, Low operating investment, Long-term reliability.

- The output is up to 60 tons/hour, which meets the needs of large-scale production.

- The product line has perfect function configuration, no process waste due to optimum material recycling.

- All kinds of plant components are complete, rapid change of wear parts.

- High purity (rubber/steel), high proceeds from final products.