Hammer Crusher

ProductThe GHC series heavy-duty hammer crusher is an efficient crushing equipment designed for fine processing of waste materials such as scrap metals, electronic waste, household appliances. It has strong crushing ability and multi-functionality, with one-time crushing and kneading processing, which can effectively reduce the size of waste materials and achieve the separation of useful substances and pollutants in waste materials, improving the quality of finished products. The metals processed by this equipment have high density, high purity, convenient transportation, and high recycling value, which can meet the requirements of steel mills for “feeding refined materials into the furnace”.

GDI Series Shredder is a multi-purpose dual-shaft shredder for reducing industrial and commercial wastes. It shreds various materials into optimum shapes and sizes for recycling, incineration, or landfill. GDI has unimaginable stability and is always reliable, which makes it possible to cope with the demand for waste disposal under the harshest working conditions.

Four-Shaft Shredder

ProductFour-Shaft shredder is a multi-purpose shredder. It has the same working principle as two-shaft shredder. GF Series four-shaft shredder can control the final material size by equipping a screen at the outlet. Four-shaft fine shredder provides greater shearing force than two-shaft shredder, it can handle all kinds of toughness, ductility of waste materials and obtain consistent shape and size.

The project is the third phase expansion project of Macao Waste Incineration Center invested and constructed by the Macao Special Administrative Region Government, with a daily waste processing capacity of 1,300 tons. GEP provides a complete set of waste tire shredding line, and the shredded tires are incinerated for power generation. Customers have very strict requirements on equipment quality control, and the engineering uses international first-line brand equipment. GEP's equipment has reached a high international level from performance design, quality control to on-site installation and commissioning.

The recycling and processing capacity of the waste sorting center is 200,000 tons per year, which means a daily processing capacity of about 550 tons of waste. The processed materials include recyclables, bulky waste, metal waste, plastic waste, waste paper, and so on. The center cooperates with the front-end recyclable system to collect, classify, sort, shred, and compress recyclable materials in the area.

Behind the prosperity of the local leather processing industry, waste materials such as waste leather and waste textiles have caused serious environmental pollution and become a focus of public attention. As a result, the government has consolidated and shut down hundreds of related enterprises, leading to a significant decline in annual output value. In order to solve the problem of industrial solid waste restricting economic development, the local government has launched a recycling project, striving for a win-win situation between economy and environmental protection. In this project, industrial solid waste is transported to the storage pit by garbage collection trucks, and then shredded to a size of 150-200mm by a double shaft shredder, and mixed with sludge for co-firing. Since the project started, the equipment has been in good condition and the size of the shredded materials meets the standard. This effectively alleviates the environmental problems caused by the leather processing industry and explores

It is profitable to do construction waste recycling. The prerequisites must be in compliance with local laws and regulations, and relevant legal procedures must be handled, as well as environmental protection measures. According to users who have been in production for many years, the construction waste is mainly some wastes such as muck, concrete blocks, crushed stones, bricks and tiles, asphalt blocks, etc. After being processed by construction waste recycling equipment, 85% can be used for Sand, pebbles, 10% impurities, 5% scrap metal, the finished product particle size, wear resistance, moisture content, etc. must meet the parameter standards of construction sand, it is very easy to sell (about 50-102 ¥ / ton).Working 8-10 hours a day, the output is 800-1000 tons, the average price of recycled aggregate is about 50¥/ton, the daily profit is (800-1000) x 50¥= about 4-50,000¥, the annual profit of construction waste recycling plant is more than 1 million¥ , and the relevant departments will have policy

Project Overview:The construction waste recycling project is located in the suburbs of Moscow, Russia, with a processing capacity of 100 tons per hour. Its purpose is to clean up the demolition waste of buildings in Moscow city and reuse the recycled materials into building aggregates. The project produces four different specifications of finished materials, namely 0-5mm, 5-20mm, 20-40mm, and 40-70mm.This construction waste recycling line equipment includes crushing system, conveying system, sorting system, screening system, dust reduction system, and intelligent integrated control system. The advantage of this equipment combination is that the process flow is reasonable and smooth, which can improve the utilization rate of garbage resources and impurity separation rate, ensure the quality of recycled aggregates, and extend the service life of related equipment.Overall, this project not only contributes to environmental protection, but also provides high-quality and renewable building aggregates, creating

With the rapid development of China's urbanization process and municipal infrastructure construction, as well as the renovation of old residential areas and factories, demolition and renovation of urban villages and other projects, the production of construction waste in China has increased year by year. According to statistics, the production of construction waste in 2021 has reached 3.209 billion tons. Therefore, the national policy has been advocating the reduction and resource treatment of construction waste, which is of great significance to save resources and protect the environment.We all know that construction waste through crushing, sorting and other links can finally get valuable sand and stone aggregate, metal and some fuel, sand and stone aggregate can be used to make concrete for the construction of buildings, roads, Bridges and other construction, metal can be sold, light fuel can be incinerated for power generation, garbage is misplaced resources can be said to be reflected incisively and

20 April 2023, the second day of the 24th China Environment Expo. The 17 halls of the Shanghai New International Expo Centre were bustling with people, booths of different styles and 2,407 exhibitors offering their best.Located at stand E72/D72 in Hall W1, GEP ECOTECH is still going strong and hot: a constant stream of visitors at the reception desk, a full house of business negotiators and sales managers working in an orderly manner. Of course, we also continued to attract the attention of industry experts, upstream and downstream enterprises and the press.Three Powerful Resourceful SystemsIn addition to the four-shaft shredder and the third-generation European version of the fine shredder shining in the W1 waste treatment and recycling pavilion, our industrial waste recycling system, domestic waste recycling system and construction waste recycling system were also highly sought after.Industrial Waste Recycling SystemWith the intelligent operation management system as the core, the system enables high

"This is my exercise book exchanged with waste batteries!" In August 3rd, Huzhuang village Miaoxia town, the 13 year old Hu Mengbin very happy, and said proudly, he has account in the village e-commerce service center, he collects toxic and hazardous waste from home and street to exchange points from village e-commerce service center, the points can be used to exchange school things, his goal is to accumulate 100 points.In the village's e-commerce service center, the wall prominent position hanging garbage exchange points system, garbage payment standards and other schematic. The villagers can be plastic bags, waste batteries, waste pesticide bottles, bad bulb and other toxic and hazardous waste sent to exchange points, points accumulated to a certain grade, can be exchanged for toilet paper, soap, pencils, exercise books and other 12 kinds of daily necessities and school things. There is also a special account book which clearly records the villagers' garbage collection. "I was running rural Taobao, heard

More and more customers purchase waste tire shredder, which are mainly used in the field of waste tire recycling. The recycling of waste tires mainly adopts the way of crushing and recycling. The collected waste tires are crushed and then widely used in various fields.In terms of policy, technology, equipment and market, it is a good time to invest and develop waste tires!According to the market demand, GEP ECOTECH has developed GDT tire crusher equipment. The equipment is an environmental protection and energy-saving tire crushing equipment with the design concept of energy saving, consumption reduction and emission reduction, and its technical indicators meet the national standards. The tool is forged with imported materials from Europe, which is durable and has a good crushing effect on the steel wire in the tire. The overall structure is compact, low speed, high torque, low vibration, low noise, in line with the requirements of environmental protection.The price of waste tire shredder is related to the

MSW reduction and recyclables recycling have become popular treatment methodsMSW(Municipal solid waste) has a wide range of sources, including daily waste, such as food waste, plastics, films, clothing, cans and product packaging. Due to the limitations of the shortcomings of landfills, municipal solid waste disposal is facing increasing pressure. In recent years, the reduction of municipal solid waste and the reuse of recyclables have become popular treatment methods.Shredder is the key equipment for MSW reductionThe municipal solid waste treatment and recycling system has a variety of models of slow waste shredders, drum screens, screening machines, material sorters, flip screens and recycling equipment, which can crush, screen and separate valuable materials in municipal municipal solid waste . Among them, the shredder is the key equipment for the treatment of municipal solid waste, which can affect the disposal effect of the entire production line. So which type of crusher is used for municipal solid

There are various industrial copper wire shredder machines available for sale, which can be used to process copper wires and cables into smaller pieces for further recycling or refining. Here are some of the options available:Waste copper wireDual Shaft Shredders: These are heavy-duty machines that are designed to process large volumes of copper wires and cables. They feature two rotating shafts with sharp blades that shred the materials into smaller pieces.Single Shaft Shredders: These are similar to dual shaft shredders, but feature only one rotating shaft with blades. They are designed for medium-sized material processing and are commonly used for copper wires finer shredding.Granulators: These machines use a combination of shredding and granulating to process copper wires and cables into smaller pieces. The copper pieces are then sorted and separated by size or density.When purchasing an industrial copper wire shredder machine, it is important to consider the specific needs of the recycling operation,

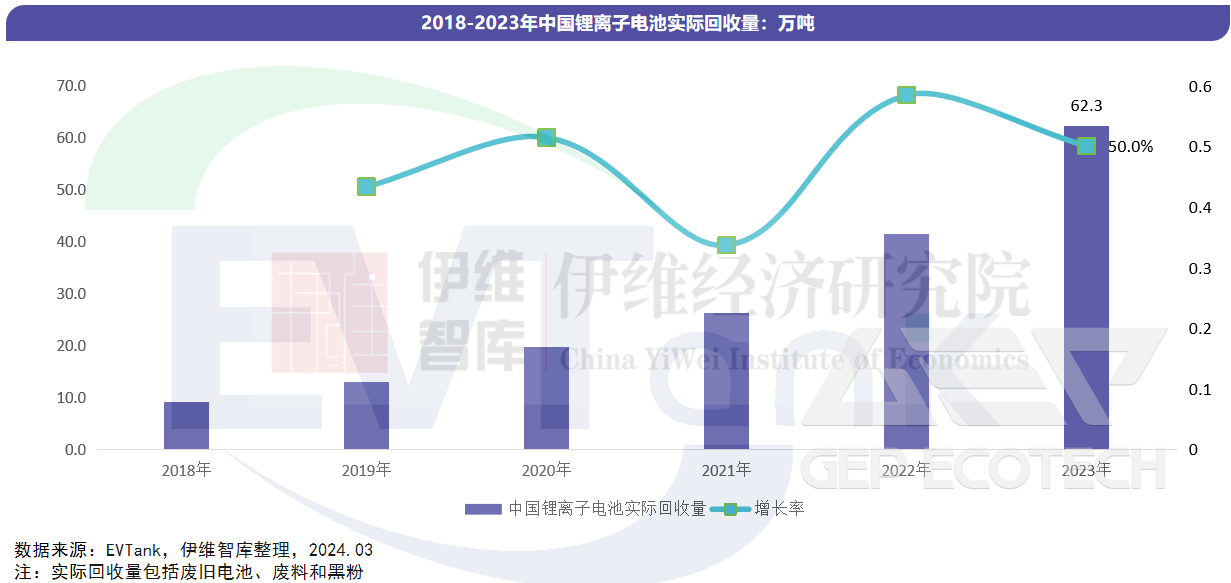

Power battery recycling is one of the hot topics in the environmental protection industry.Starting from 2022, China's power batteries will gradually enter the large-scale retirement period. In 2023, the retirement volume will be about 24GWh. It is estimated that by 2028, this figure will exceed the 100GWh mark.Previously, due to the continuous surge in the prices of raw materials for power batteries, the field of power battery recycling at the end of the industrial chain has attracted unprecedented attention and attracted a large influx of capital.However, the White Paper on the Development of China's Lithium-ion Battery Recycling, Disassembly and Echelon Utilization Industry (2024) pointed out that although the actual recycling of lithium-ion batteries nationwide has reached 623,000 tons in 2023, the recycling rate has hovered at less than 25%, highlighting the huge space for improvement in efficiency and scale of the current recycling system.High recycling costs, complex processing procedures, and

With the rapid development of the city, we will inevitably produce domestic waste in our life. There are many types of domestic waste, and the process is also more complex. In the process of treatment, the domestic waste shredder is essential, which needs to crush the domestic waste and then carry out the follow-up work.Many environmental protection disposal companies will purchase domestic waste shredder. Now there are many domestic waste shredder products. Different businesses sell different shredder products, and the price is also different. How to choose the domestic waste shredder, let GEP ECOTECH talk with you.Now there are many domestic waste shredder manufacturers, each manufacturer's production process is different, the price of domestic waste shredder is also different. When choosing, we must keep our eyes open. Some cheap shredder equipment may not be of good quality. As the saying goes, "one price for one goods", what price of shredder equipment is what kind of quality.Although there are many

Mobile jaw crushing plant are designed for primary crushing rocks or C&D wastes of any strength to produce or recycle crushed stone and aggregate. The principle operation of a mobile jaw crusher is based on the compression of the material by the working surfaces (cheeks), which leads to its destruction and crushing. Only the crushing jaws are subject to wear in jaw crushers, the side walls are not involved in the crushing process. Mobile jaw crushers are rightfully considered one of the most reliable and productive types crushers for primary crushing , they are versatile and capable of crushing any kind of rock (from granite to construction and demolition waste). Depending on the kinds of raw material, the jaws with different strength are installed on the crusher. Mobile jaw crushers are presented in a self-propelled version that on a tracked chassis and in a semi-mobile version that on a frame with tires . Mobile crushers with a self-propelled tracked chassis are equipped with a control panel installed on

Waste-to-energy (WtE) plants are designed to efficiently handle, sort, and process different types of waste materials to convert them into energy. Different types of waste disposal equipment are needed for various stages from waste to energy. Here are some of the most common waste disposal equipment used in WtE plants:Waste conveyors: Conveyors are systems for transporting waste from the bunkers to material pre-treatment areas. The conveyor systems can be designed to carry heavy or light materials such as waste bags, glass bottles, cans, or organic waste.Shredders: Shredders are used to break down and reduce the size of waste. This process is necessary for increased efficiency in the subsequent processes.Waste dryers: Solid waste can contain a high moisture content, which reduces the heating value and energy of the waste. Drying systems such as rotary dryers or fluidized bed dryers are used to reduce the water content of waste, making it more suitable for combustion.Recyclable waste separators: The waste