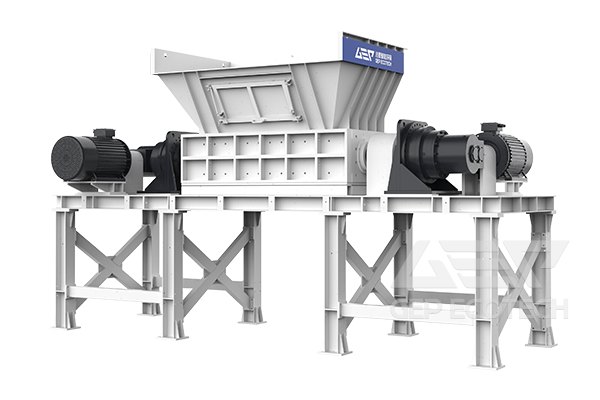

| Model | Capacity (t/h) | Output size (mm) | Dimension (mm) |

| GDI8 | 5-10 | 100-300 | 5000×2650×3300 |

| GDI9 | 8-15 | 5300×2750×3400 | |

| GDI10 | 10-20 | 5500×2850×3500 | |

| GDI12 | 15-30 | 6000×3250×3600 | |

| GDI13 | 20-40 | 6400×3500×4000 | |

| GDI15 | 30-50 | 6900×3700×4500 |

Note: Technical specifications may change without notice due to ongoing technological advancements.