Waste tires are known as "black gold mines" and are of great recycling value. For example, direct retreading and reuse, recycling steel wire to make steel, rubber grinding to make rubber powder, pyrolysis to make oil, cement rotary kiln or power station alternative fuel (TDF), etc., the benefits are considerable.

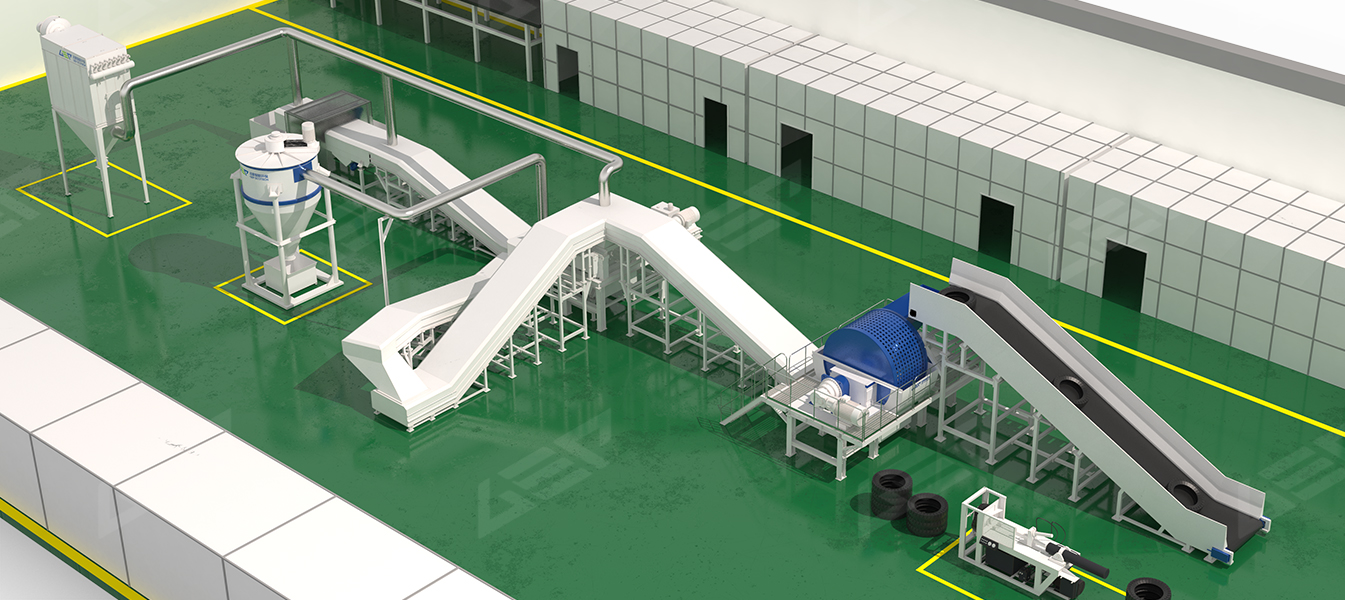

Market data shows that recycled products from shredding and grinding of waste tires are more expensive than directly recycled tires. GEP ECOTECH has been working with waste tires for many years and offers a wide range of options for recycling waste tires.

Shredding and grinding: complete waste tires are shredded and ground to remove non-rubber impurities (nylon fibres, steel wires) to obtain different mesh sizes of pure rubber powder. These materials can be used to make recycled rubber, modified asphalt, runways and other products.

Cracking pre-treatment: After being shredded into blocks and separated from the steel wire, waste tires are sent to a pyrolysis reactor where they are made into oil for use as fuel, combustible gas for power generation and carbon black, which is more expensive on the market.

Making TDF: The calorific value of waste tires is over 8000 kcal, which is higher than burning coal at 5000 kcal. Cement plants, power plants, steel plants and smelters in many European and American countries use shredded waste tires as fuel to reduce production costs for their companies.

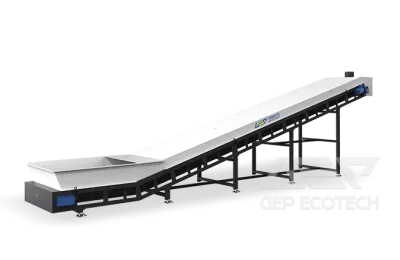

GEP ECOTECH designs professional and reliable tire recycling solutions based on project requirements. We guarantee our customers the highest production quality and recovery rates, while reducing energy consumption and production costs.