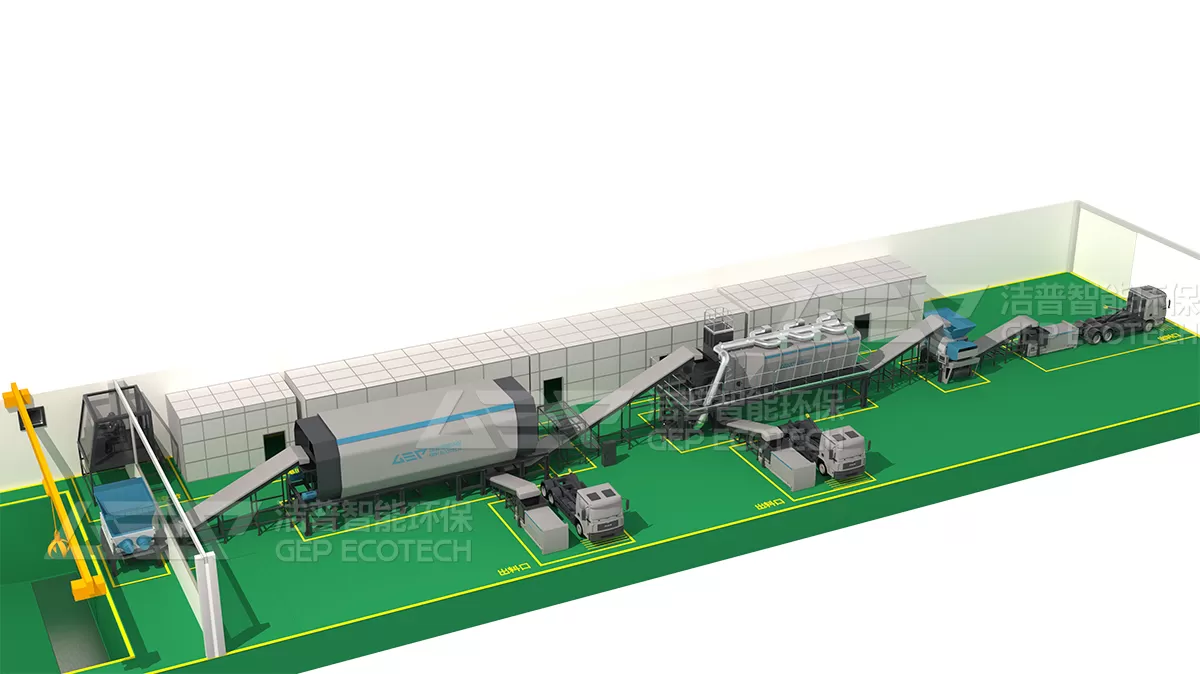

Domestic Waste Shredding&Recycling System in Qatar

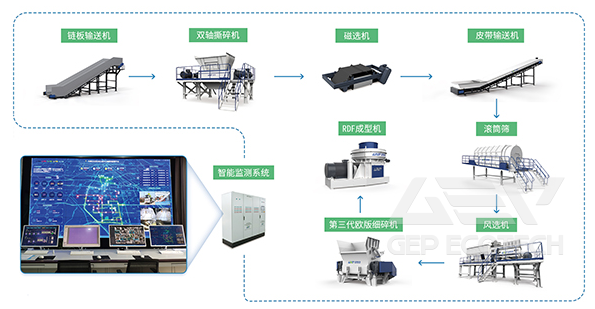

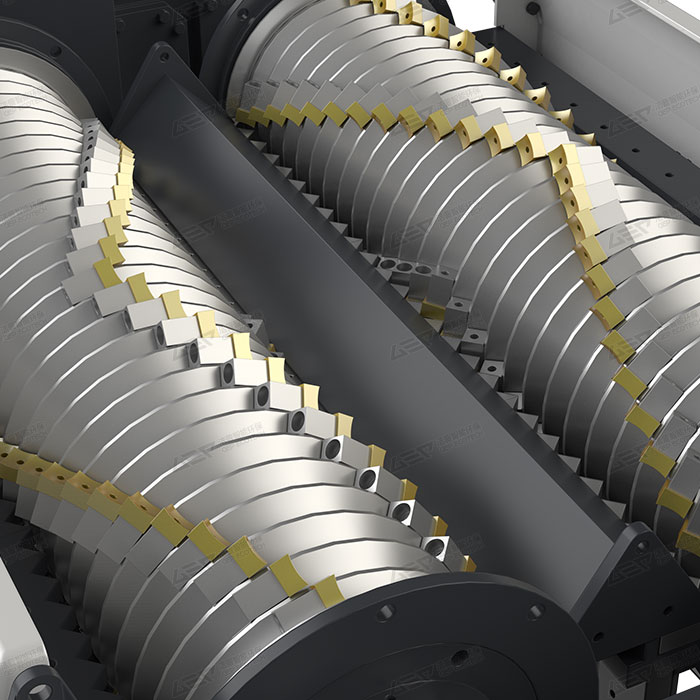

Project OverviewGEP ECOTECH has successfully commissioned a customized domestic waste shredding line in Qatar, designed to efficiently process municipal solid waste (MSW) and produce Refuse-Derived Fuel (RDF) for energy recovery. System Configuration & Process FlowTo meet the client's requirements for high capacity, reliability, and automation, the shredding line integrates:Primary Shredding – Heavy-duty dual-shaft shredder (GD series) for coarse size reductionSorting System – Magnetic separator (metal…

Learn MoreRDF Project with an Annual Output of 55,000 Tons in the Middle East

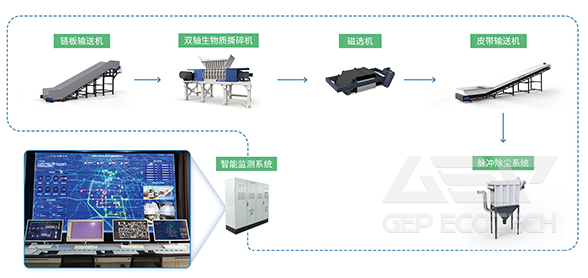

GEP ECOTECH provided a customized RDF production solution for the first waste-derived fuel (RDF) plant in a Middle Eastern country, deploying multiple RDF preparation units to build an intelligent production line with an annual capacity of 55,000 tons. The project integrates wheel loader feeding, intelligent sorting, belt conveying, precise dosing, and pelletizing, while continuously monitoring key indicators such as moisture and calorific value to ensure product quality. This solution facilitates the…

Learn MoreLight Materials From Decoration Waste Can Be Transformed Into Fuel in Seconds

Energy Treasure: Re evaluation of the Value of Light Materials in Decoration WasteAbout 30% of the light materials in decoration waste, such as wood, plastic, fabrics, etc., contain enormous energy value. These combustibles can be scientifically processed and converted into solid recycled fuel (SRF) and waste derived fuel (RDF), with a calorific value of 3500-6000 kcal/kg, close to the level of coal. This transformation not only reduces the land resources occupied by landfilling, but also reduces 1.5 tons…

Learn MoreAnnual Production Of 100000 Tons Of Alternative Fuel, See How Waste Spinning Transforms Into a 'Green Fuel Warehouse' In The Cement Industry

Driven by carbon peaking and carbon neutrality goals, China continues to promote the clean transformation of high emission industries. With the "14th Five Year Plan" for the development of circular economy clearly proposing the "coordinated disposal of urban waste by cement kilns and smelting kilns" and the "Special Action Plan for Energy Conservation and Carbon Reduction in the Cement Industry" requiring the proportion of production lines using alternative fuel technology in cement kilns to reach 30% by…

Learn MoreHow to Process Palm Fruit Fiber into RDF Alternative Fuel

Palm fruit fiber, a byproduct of palm oil production, has the potential to be transformed into Refuse-Derived Fuel (RDF) as an alternative energy source. With its renewable nature, calorific value, and abundant supply in palm-producing regions, palm fruit fiber can be processed into RDF through several steps. Collection and Drying: Collect the raw fiber from palm oil mills and reduce its high moisture content (40–60%) using rotary dryers or solar drying to below 15%.Size Reduction: Shred and grind the…

Learn MoreIndustrial Shredders in Converting Waste to Fuel

As industries strive to address environmental challenges and enhance sustainability, converting waste into fuel has emerged as a significant solution. Industrial shredders play a pivotal role in this process by preparing waste materials for transformation into valuable energy sources. This article examines the function of industrial shredders in waste-to-fuel projects and explores the types of shredders commonly used in these applications.Role of Industrial Shredders in Waste-to-Fuel ProjectsIndustrial…

Learn MoreAdvanced RDF Treatment Line for Industrial Waste Management in France

Project profileThe customer is a strong company that does resource disposal of industrial solid waste in China. The processing materials are mainly combustible such as plastic bags, oily paper, waste clothing, and seasonal straw. Through the fully automated shredding, sorting and RDF molding process configured by GEP ECOTECH, industrial solid waste is converted into high-density and high-calorific RDF fuel, which is then sold to local coal-fired power plants for use, reducing coal consumption, reducing…

Learn MoreHow To Turn Waste Into Fuel?

The global population growth, urbanization process, and continuous improvement of living standards have all accelerated the generation of waste. The shortage of raw materials and the growing demand for energy have led us to focus on these wastes. The waste to fuel technology provides an environmentally friendly and economical solution to these global environmental problems. GEP has also joined the development of this technology and developed a complete solution that can convert waste into environmentally…

Learn MoreWhat Are the RDF Production Facilities?

The word RDF is familiar to people in the environmental protection industry, especially in the context of dual-carbon, the surging market demand for alternative fuels and the rise of domestic waste resources, making RDF the outlet of solid waste treatment in the past two years. Therefore, with the rise of the market, as a solid waste treatment manufacturer, we often receive customers' questions about the production equipment of RDF. To return to this question, we have to answer from the following aspects:…

Learn MoreIntroduction to GEP ECOTECH Cement Kiln Alternative Fuel (SRF/RDF) Preparation System

GEP ECOTECH is a national high-tech enterprise driven by technological innovation and social responsibility, a provincial-level solid waste equipment technology research center, a provincial-level specialized and refined new enterprise, and a high-quality alternative fuel preparation solution and equipment supplier for cement kilns. The company's business scope covers five major fields in the construction of the national "waste free city", including industry, agriculture, daily life, construction, and…

Learn MoreAlternative Fuels For Cement Companies, See The GEP's Solution

Jointly hosted by China Building Materials Circulation Association (CBMCA), China Cement Technology Network (CCTN) and China Cement Building Materials Centre, Beijing (BCMC), the "2023 Cement Industry Upgrading and Efficiency Enhancement and Intelligent New Technology and Equipment Exchange Conference under the Background of Dual-Carbon" was successfully held on 26th - 28th July 2023 at Zhengzhou Chantilly Bay Hotel. Industry technical experts, scientific research units, colleges and universities, cement…

Learn MoreRDF Line for Bulky Municipal Waste

An RDF (Refuse-Derived Fuel) line for bulky municipal waste is a specialized waste processing system designed to convert large and non-homogenous waste, typically generated from households and businesses, into a more uniform and energy-rich fuel. This technology aims to optimize waste management and utilize the energy potential of bulky municipal waste while reducing its environmental impact. Below, we will explore the key components and processes involved in an RDF line for bulky municipal waste.Waste…

Learn MoreOperation of Solid Waste Molding Unit

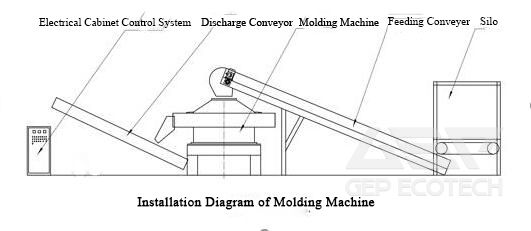

Refuse derived fuel RDF is a fuel made by crushing, sorting, drying, adding chemicals, and compressing combustible waste. In the compression molding process, solid waste molding units are generally used, which include the feeding system, molding system, iron removal system, discharge system, heating system, and electrical cabinet control system.Install1. Place the molding machine on a solid and flat ground.2. Place the feeding conveyor in position, adjust the distance to the molding machine and seal it.3.…

Learn MoreEssential Equipment for Solid Waste Recycling - RDF Forming Machine

The GPM series RDF forming machine is a solid waste terminal resource utilization equipment developed by GEP, which combines the advantages of similar products. The original design of pressing wheel, module, anti stuffiness machine, full-automatic oil pump, etc., makes it have the advantages of reasonable structure, high production efficiency, low energy consumption, strong adaptability, simple operation, reliable performance, easy movement, etc., so it is widely used in the production line for resource…

Learn MoreEquipment for Transforming Diaper Scraps into Fuel Rods

Introduction:With the increasing population and rapid urbanization, the usage of disposable products is also on the rise. Among them, diapers are a necessity for infants and adults alike, but the disposal of diaper scraps poses a challenge as they are not easily recyclable or handled efficiently. In an effort to address this issue, researchers and companies are exploring the feasibility of utilizing diaper scraps as fuel rods, reducing waste and promoting environmental benefits.Paragraph 1: The Challenges…

Learn MoreHow Long Does the RDF Forming Machine Material Take to Be Extruded in the Mold?

The time when the material is extruded in the mold is one of the most important factors in the operating parameters of the RDF forming machine. The length of its forming time depends on the adjustment of the operating parameters of the forming machine, including the mold size, extrusion speed and extrusion pressure.First of all, the mold size is an important factor affecting the extrusion time. The smaller the mold size, the shorter the extrusion time, and the smaller the size of the extruded molded fuel…

Learn MoreRDF Preparation Technology, One of the Waste Furniture Recycling Methods

IntroductionWith the acceleration of urbanization, the disposal of used furniture has become an urgent problem. Traditional disposal methods mainly include landfill and incineration, which not only cause environmental pollution but also waste a lot of resources. Therefore, RDF production technology, as a new type of used furniture treatment technology, has gradually received attention and attention from people.Principles and Process of RDF TechnologyRDF technology refers to the processing of combustible…

Learn MoreProcessing Bulky Waste and Garden Waste to Produce Refuse-Derived Fuel (RDF) in Jiangxi, China

Multi-stage shredding + multi-stage sorting + pelleting, from waste to fuel that is sought after in the market, can actually be so simple!

Learn MoreWhat Equipment Does It Take to Recycle Industrial Solid Waste into RDF Fuel Rods?

Industrial production will produce a lot of waste, along with the development of our country economy, industrial waste more and more, along with the development of national environmental protection, industrial solid waste must be properly treated, under the background of "no waste city", the treatment requirements of the industrial solid waste is higher, not only harmless treatment, at the same time must carry out resources utilization. General industrial solid waste in the narrow sense, we usually refer…

Learn MoreHow Much RDF Can One Ton of Household Waste Produce?

The amount of RDF (Refuse-Derived Fuel) that can be produced from one ton of household waste can vary depending on several factors, such as the composition of the waste, the efficiency of the RDF production process, and the technology used for RDF production.Generally, it is estimated that one ton of household waste can produce around 150-250 kg of RDF. However, it should be noted that this is just an average estimate based on preliminary sorting of the waste to remove recyclable materials.The composition…

Learn MoreIndustrial waste RDF production line

Industrial waste is generated in the process of industrial production, which will cause great pollution to the environment if it is not properly disposed of. In recent years, one of the emerging solutions is to make industrial waste into RDF alternative fuel.RDF stands for Refuse Derived Fuel, or "waste as fuel", which is a kind of solid fuel derived from combustible wastes through sorting, crushing, drying and other processes. This fuel is widely used in industry (cement kiln co-disposal, etc.) and in…

Learn MoreHow Much Is RDF Fuel Rod per Ton?

What is the most popular concept of solid waste treatment? RDF fuel rods are definitely on the list. RDF, short for RefuseDerivedFuel, has high caloric value, stable combustion, easy transportation, easy storage, low secondary pollution and low emissions of dioxins, and is widely used in drying engineering, cement manufacturing, heating engineering and power generation.So in the context of the two-carbon target, RDF technology becomes popular, opening up more possibilities for recycling waste. Therefore,…

Learn More5 Ton per Hour Single Shaft Shredder for Industrial Waste to RDF Project

In the Zhejiang industrial waste to RDF project that was put into operation recently, we used the new third-generation single-shaft shredder optimized and upgraded by GEP, with a capacity of 5 tons per hour. This new single-shaft shredder has continuous high throughput and uniform output granularity, and can easily shred thick plastic pipes, twisted ropes, plastic bags, leather, waste clothes, etc. The strong wear-resistant structure is ideal choice for harsh recycling tasks. The new single-shaft shredder…

Learn MoreCan Waste Woven Bags Be Made into RDF?

Recently, a customer asked us whether waste woven bags can be turned into RDF? The answer is yes, because woven bags are a kind of plastic, and plastic is a very suitable high-calorie fuel. If used properly, it could partially replace fossil fuels such as coal or oil in cement production. So how to make RDF from waste woven bags? Let's find out together.Process of making RDF from waste woven bagsWaste woven bags are very common, and it should be encouraged and developed to make them into RDF as an…

Learn MoreRDF Production Line

RDF production line consists of shredding, sorting system and pelleting system. Firstly, the solid waste is shredded, combustibles are sorted out, and then dried, and finally extruded to make a granular material—RDF.

Learn MoreWhether Decoration Waste Can Be Made into RDF?

Recycling of decoration waste is the general trend. Recently, many customers have asked whether decoration waste can be made into RDF? The answer is yes. The high-calorific-value lightweight materials sorted out after the pretreatment of decoration waste include bamboo, wood, fabric, plastic, and woven bags, etc., combined with the current on-site operation of some decoration waste treatment plants, they are usually mixed with some bulky waste and domestic waste.The realization of a high level of resource…

Learn MoreSolid Recovery Fuel Preparation Technology

Solid recovered fuel is prepared from non-hazardous waste and used in incineration plants or collaborative incineration facilities to achieve energy recovery and reuse.At present, the main solid recovery fuel preparation technologies include drying and mechanical separation. Drying can be divided into thermal drying and biological drying. Thermal drying is to heat domestic waste through external heat sources to reduce the moisture content of materials in various forms, while biological drying is mainly to…

Learn MoreRDF Pelleting Mill

GPM series RDF pelleting mill is designed with original pressing wheel, module, anti-stuck machine, automatic oil pump, etc. It can make industrial waste, domestic waste, biomass straw, etc. into granular, high-density, high burning value RDF fuel. The equipment has the advantages of reasonable structure, high production efficiency, low energy consumption, strong adaptability, simple operation, reliable performance, easy movement, etc.

Learn MoreMSW(Municipal Solid Waste) To RDF(Refuse Derived Fuel)

The rate of MSW generated every year is increasing. Therefore, it is an urgent task to seek a resource-based treatment approach for MSW. Converting MSW into refuse derived fuel, or RDF, is a relatively mature waste treatment method in developed countries. The United States, Europe, Japan, South Korea and other countries have widely used RDF fuel for power generation or heating.How does MSW become RDF?The production process of RDF fuel is to first classify the municipal solid waste with sorting equipment,…

Learn MoreIndustrial Solid Waste to RDF Production Plant in Zhejiang, China

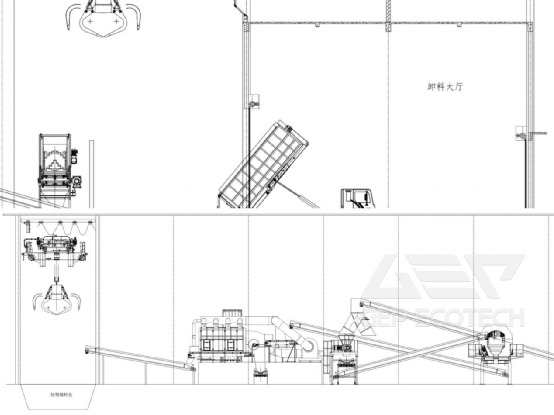

The equipment of this project consists of the third-generation fine shredder, chain conveyor, belt conveyor, magnetic separator, uniform feeder and RDF pellet mill. Through fully automated crushing, sorting and molding processes, industrial solid wastes such as plastic bags, oil paper, waste clothes and other combustible materials are converted into RDF with high calorific value, which are sold to local coal-fired power plants to reduce coal consumption and carbon emissions while gaining considerable…

Learn MoreWhat is the complete set of equipment for processing domestic waste into RDF?

Today, a customer asked me what the complete set of equipment for RDF processing from domestic waste is. The raw materials are mainly furniture, mattresses, sofas, fabrics, leather in domestic waste. The output requirements are about 800 tons per month. The complete set of equipment for processing domestic waste into RDF generally includes: primary shredder, sorting equipment, fine shredder, drying treatment, press forming equipment, etc. Let us briefly understand a few of these steps.Primary shredderWith…

Learn More