GEP ECOTECH is a national high-tech enterprise driven by technological innovation and social responsibility, a provincial-level solid waste equipment technology research center, a provincial-level specialized and refined new enterprise, and a high-quality alternative fuel preparation solution and equipment supplier for cement kilns. The company's business scope covers five major fields in the construction of the national "waste free city", including industry, agriculture, daily life, construction, and hazardous waste. More than 300 projects have been successfully put into operation. The company has a modern equipment manufacturing base of 66000 square meters, a complete production line of CNC precision machining equipment, and independently developed and produced crushing systems, sorting systems, terminal resource utilization systems, and intelligent monitoring systems that have won over 100 national patents and technical software works, selling well in over 70 countries on six continents worldwide.

General Industrial Solid Waste Preparation Alternative Fuel System

The general industrial solid waste preparation alternative fuel (SRF/RDF) system consists of a dedicated double-shaft industrial waste shredder, third-generation European version fine shredder, magnetic separator, RDF forming machine, hydraulic packaging machine, chain conveyor, belt conveyor, and GI intelligent monitoring system. After crushing and sorting, general industrial solid waste is transported by bidirectional belts to terminal resource utilization equipment such as RDF forming machines and hydraulic packaging machines, and made into alternative fuels of different specifications (RDF molding materials and SRF bulk materials). Finally, it is transported to cement plants and thermal power plants for incineration, which not only reduces carbon emissions but also successfully solves the problem of solid waste.

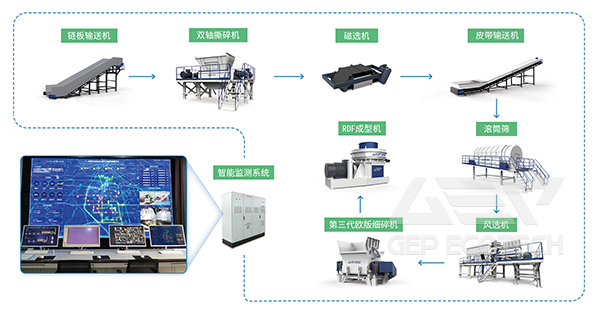

Domestic Waste Preparation Alternative Fuel System

The domestic waste preparation alternative fuel (SRF/RDF) system consists of a double-shaft shredder, third-generation European version fine shredder, magnetic separator, rotary drum screen, wind sifter, RDF forming machine, chain conveyor, belt conveyor, and GI intelligent monitoring system. Domestic waste with complex components undergoes a series of processes such as crushing, magnetic separation, screening, and wind separation. Heavy substances can be directly compressed, packaged, and sent to cement plants for fuel replacement; Light substances are then finely crushed and shaped to produce RDF fuel with high combustion value and high profit.

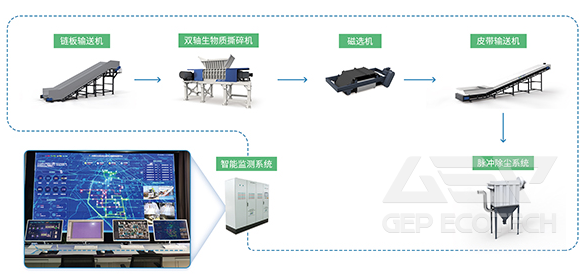

Biomass Preparation Alternative Fuel System

The biomass preparation alternative fuel (SRF/RDF) system consists of a double-shaft biomass shredder, magnetic separator, chain conveyor, belt conveyor, intelligent monitoring system, and pulse dust removal system. This system is suitable for preparing alternative fuels from agricultural waste such as corn straw, wheat straw, rice straw, cotton straw, as well as forestry waste such as shrubs, fallen trees, branches, and tree stumps. The process is simple, the processing capacity is large, and it is stable and reliable.

Welcome to inquire about our cement kiln alternative fuel (SRF/RDF) preparation system.