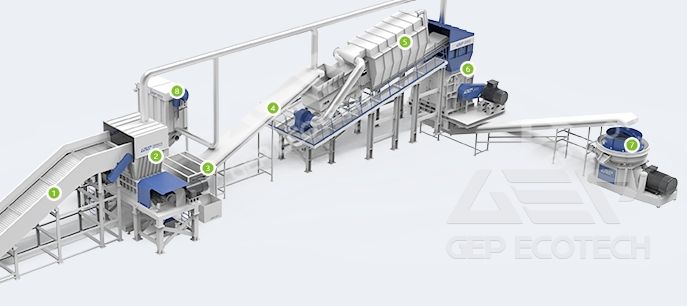

To support large-scale Black Soldier Fly (BSF) rearing projects, we offer a high-performance organic waste pre-processing line specifically engineered to convert mixed food waste and fruit/vegetable scraps into a homogeneous fine substrate (< 10 mm) suitable for optimal BSF larvae growth.

Process Flow Description

1. Feeding & Buffering System

Organic waste is fed into a stainless steel infeed hopper, equipped with a discharge screw conveyor to regulate material flow and ensure uniform feeding into the shredding stage. This design prevents material bridging and enables continuous operation.

2. Primary Shredding – Double-Shaft Shredder

The first processing stage uses a low-speed, high-torque double-shaft shredder, capable of efficiently breaking down mixed organic waste, including:

- Fibrous food residues

- Small bones

- Soft packaging contaminants

Key advantages:

- Excellent resistance to overload and jamming

- Gentle tearing action suitable for wet and sticky materials

- Auto-reverse function for jam protection

3. Metal Removal – Magnetic Overband Separator

After primary size reduction, material passes under a magnetic overband separator, which removes ferrous contaminants such as metal fragments, cans, or utensils. This step protects downstream equipment and improves the quality of the final BSF feed substrate.

4. Secondary Grinding – Wet Hammer Mill / Fine Grinder

The pre-shredded organic material is then processed through a wet hammer mill or fine grinder, reducing particle size to < 10 mm and producing a slurry or paste-like texture.

5. Discharge & Transfer

The final processed substrate is conveyed via a stainless steel output screw conveyor to storage tanks or directly to BSF feeding systems.

Key System Benefits for BSF Projects

- Produces fine, consistent BSF feed substrate

- Handles heterogeneous organic waste with minimal pre-sorting

- Corrosion-resistant design for long service life

- Continuous operation for large-scale BSF farms

- Modular design for easy expansion and integration

Typical Technical Configuration (Indicative)

- Processing capacity: 4–5 TPH

- Primary shredder motor power: 2 × 45–75 kW (depending on waste composition)

- Secondary grinder motor power: 55–90 kW

- Magnetic separator: Self-cleaning overband type

- Control system: PLC + HMI

Similar Organic Waste and BSF Pre-Processing Project

BSF Project in Shanghai(Click to View Project Details)

If required, we can further tailor this solution based on:

- Local waste composition

- Space constraints

- Integration with BSF breeding and feeding systems

Feel free to contact us for a customized technical proposal.