Construction Waste Combustibles to Alternative Fuel Project in Shanghai

This project successfully transformed construction waste combustibles into high-quality alternative fuel in Shanghai for an environmental technology company. The implemented waste recycling equipment is centered around a carefully selected configuration, including the vibrating feeder, ballistic screen, magnetic separator, single shaft shredder, waste baler, etc., forming a complete and efficient alternative fuel production line. The system delivers stable output of 3–5 tons per hour, providing reliable…

Learn MoreAlternative Fuel Production Line in Henan, China

This project for an environmental protection company in Henan is designed to process textile waste and industrial solid waste into high-quality alternative fuel for cement kilns. The upgraded production line, with a stable capacity of 6-8 tons per hour, includes key equipment such as a Double-Shaft Shredder, Wind Sifter, Single Shaft Shredder, and a choice between an RDF Pellet Mill or a Waste Baler for final densification. The system improves waste sorting efficiency and fuel uniformity. Currently…

Learn MoreLuxi Chemical Biomass Pellet Technical Renovation Project

Luxi Chemical, a famous chemical company in China, undertook a Biomass Pellet Technical Renovation Project to process garden branches and wood boards at 1-1.5 t/h into standardized fuel pellets for boiler fuel combustion. Building upon their existing line featuring a Double-Shaft Shredder (GD12) for primary shredding and a Single Shaft Shredder (GE20) for secondary reduction, the company added a crusher (SG65*75) and pelletizer (SZH560). This enhanced configuration efficiently converts the biomass waste…

Learn MoreSingle Shaft Wood Shredder

A single shaft wood shredder is an industrial machine designed to process wood waste efficiently, breaking down large and bulky materials into smaller, uniform pieces. Compared to other types of shredders, such as dual-shaft or multi-shaft models, single shaft wood shredders are known for their ability to produce consistent, finer output with a more controlled particle size. The main feature of a single shaft shredder is its simplicity and effectiveness in handling various types of wood waste, including…

Learn MoreIndustrial Plastic Waste Shredder Specifications

Industrial plastic waste shredders are essential for processing and recycling various types of plastic waste, such as packaging materials, pipes, bottles, and production scraps. These shredders come in different configurations—single-shaft, double-shaft, and four-shaft—each tailored for specific applications and material requirements.The following article will list the main features and specifications of these shredders to help you quickly find the right equipment for your project.Single-Shaft Plastic…

Learn MoreSingle Shaft vs. Double Shaft PVC Shredder Machine

PVC shredders play a crucial role in recycling and waste management by breaking down PVC materials into smaller, manageable pieces for further processing. These shredders come in two main configurations: single shaft and double shaft. Both types serve different purposes depending on the material’s nature and the desired output.Single Shaft PVC ShredderA single shaft shredder has a rotor with sharp cutting blades and a stationary screen, through which the shredded material passes once it reaches the desired…

Learn MoreMetal Shredder Machine Specifications

Metal shredders are essential machines in the recycling and waste management industries, designed to process various types of materials, including metals. This article will explore the specifications and features of three common types of metal shredders: single-shaft shredders, dual-shaft shredders, and hammer shredders.Single-Shaft ShreddersOverview: Single-shaft shredders utilize a single rotating shaft equipped with sharp blades to cut materials into smaller pieces. They are ideal for fine shredding a…

Learn MoreSingle Shaft Fine Shredder for Processing Carbon Fiber Waste

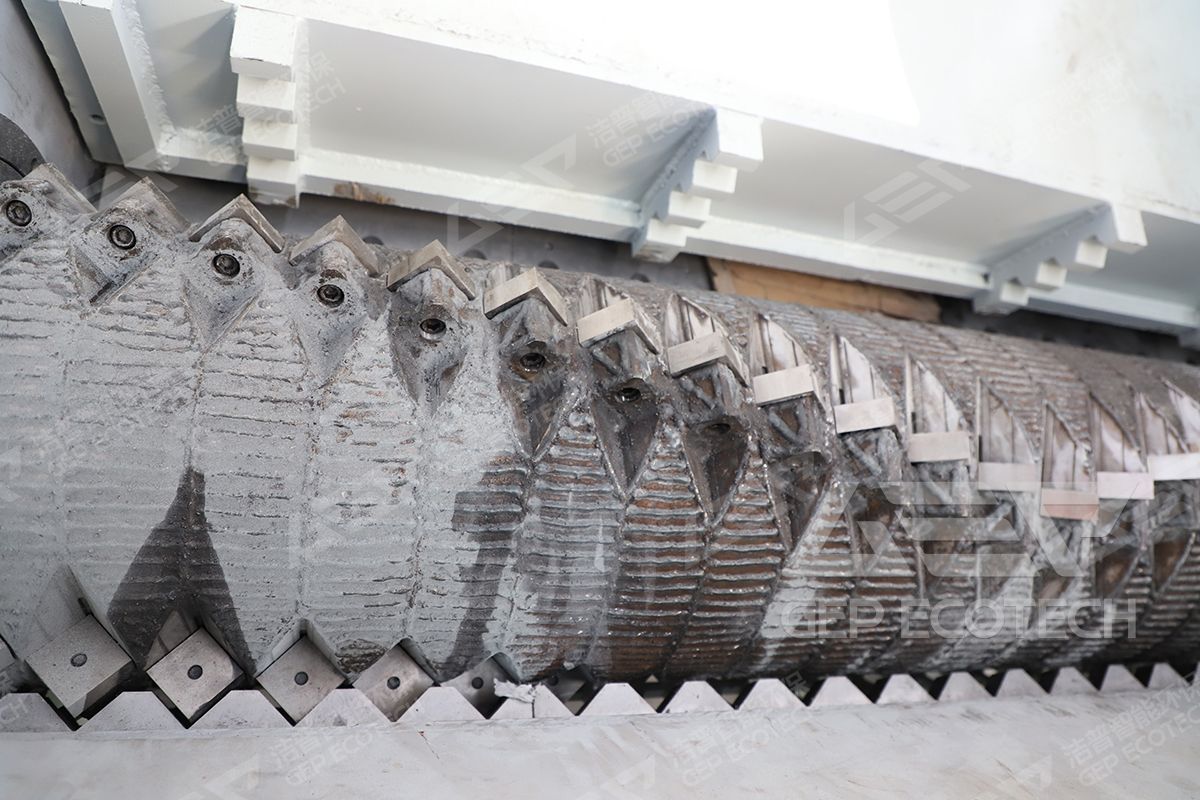

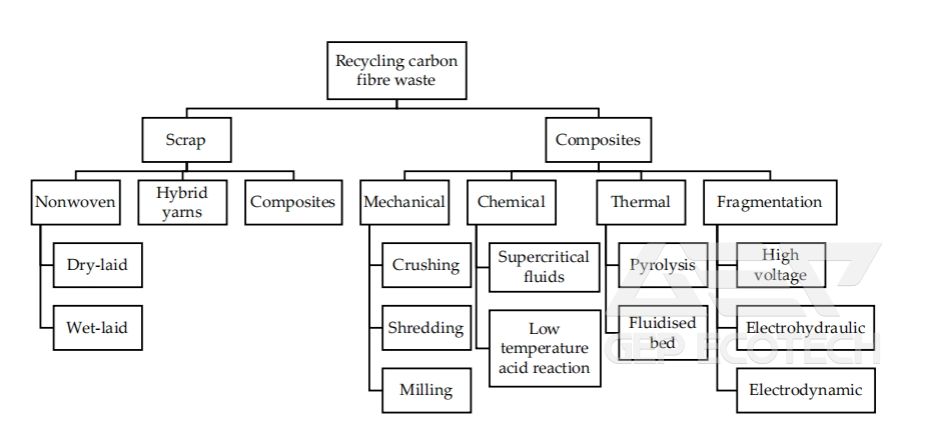

There are two main types of carbon fiber waste. The first waste is the original cut carbon fiber of products generated from dry fibers and unused expired materials, which is also called scrap. The second waste is recycled fibers from carbon fiber reinforced composites (CFRC). Depending on the different wastes, experts have studied various recycling technologies.From the above recycling methods, we can see that the shredder is a key equipment for recycling carbon fiber waste. Today I will introduce to you a…

Learn MoreShredders for Steel Swarf: Single-Shaft vs. Dual-Shaft

Steel swarf, the metal chips and shavings from machining, needs effective processing for recycling and waste management. Single-shaft and dual-shaft shredders are commonly used, each with distinct characteristics related to throughput and output size.Single-Shaft ShreddersFeatures:Design: One rotating shaft with blades.Throughput: Typically lower capacity compared to dual-shaft shredders.Output Size: Produces uniformly sized output, ideal for applications needing consistent particle size.Benefits:Cost-…

Learn MoreIndustrial Shredders in Converting Waste to Fuel

As industries strive to address environmental challenges and enhance sustainability, converting waste into fuel has emerged as a significant solution. Industrial shredders play a pivotal role in this process by preparing waste materials for transformation into valuable energy sources. This article examines the function of industrial shredders in waste-to-fuel projects and explores the types of shredders commonly used in these applications.Role of Industrial Shredders in Waste-to-Fuel ProjectsIndustrial…

Learn MoreSingle Shaft Biomass Shredder vs. Dual Shaft Biomass Shredder

When it comes to processing biomass, selecting the appropriate shredder can significantly impact the efficiency and quality of the operation. Single shaft and dual shaft shredders are two commonly used technologies, each offering distinct advantages depending on the specific requirements of the task. This article explores the key differences between single shaft and dual shaft biomass shredders, focusing on aspects such as output, particle size, and operating modes.1. OutputSingle Shaft Shredder:Single…

Learn MoreWhy Use a Fine Shredder As Secondary Process for Processing Alternative Fuels

In recent years, twin-shaft shredders have garnered widespread recognition as primary shredders in solid waste crushing applications. However, single-shaft shredders hold a distinct advantage over their double-shaft counterparts in their ability to process materials into finer sizes. Consequently, single-shaft shredders are frequently deployed as fine shredders for secondary crushing following double-shaft shredders. This is particularly evident in the realm of alternative fuel processing, where single-…

Learn MoreHigh Speed Single Shaft Shredder Malaysia

High-speed single shaft shredders are essential equipment in the field of waste management and recycling, especially in Malaysia where industrial growth and environmental consciousness go hand in hand. A high-speed single shaft shredder is designed to efficiently reduce the size of various materials, including plastic, paper, wood, and even some types of metal. This machinery is integral in the recycling process, allowing for the effective breakdown of materials into smaller, manageable pieces that can be…

Learn MoreThe 2023 Year-End Summary Is Dedicated to Everyone Who Supports and Cares About GEP ECOTECH!

Recently, good news came from E20 Environment's "2023 (17th) Solid Waste Strategy Forum": after a comprehensive selection of the company's corporate strength, project scale, typical cases, process design and other aspects by industry experts, GEP ECOTECH was awarded the "2023 Leading Enterprise in the Field of Industrial Solid Waste - Annual Growth Award for Resourceful Treatment of Industrial Solid Waste", which is an authoritative affirmation of the company's strength in the field of industrial solid…

Learn MoreSingle Shaft Industrial Insulation Paper Waste Shredding Machine with Upper Feed

The Single Shaft Shredding Machine with Upper Feed is meticulously designed to efficiently shred insulation paper waste. Its specialized construction and cutting-edge features ensure thorough and uniform shredding, reducing waste volume for easier disposal or recycling. The machine's upper feed mechanism enhances feeding efficiency and safety during operation, making it a reliable and adaptable solution for managing insulation paper waste in industrial settings.

Learn MoreSingle Shaft Shredding Machine With Upper Feed

A single shaft shredding machine with upper feed refers to a type of shredder designed with an input feed located on the top of the machine. This configuration allows materials to be fed vertically into the shredder, often by conveyor belt or manual loading, depending on the specific design.Key FeaturesSingle Shaft Design: Typically, these machines feature a single shaft equipped with sharp blades or hammers that rotate at high speeds to shred materials.Upper Feed Mechanism: The upper feed allows for easy…

Learn MoreShredding Shoes to Make Fuel Blocks

Shredding shoes to create fuel blocks involves transforming worn-out or discarded shoes into a form that can be used as a fuel source. Here's a basic overview of the process:Shoe Collection and PreparationCollection: Gather worn-out or unwanted shoes that are no longer suitable for wearing.Preparation: Remove any metal parts or non-combustible materials from the shoes. This may involve cutting the shoes into smaller pieces or manually removing elements like metal eyelets or plastic components.Shredding Proc…

Learn MoreWhat Kind of Shredder Is Used for Crushing AAC Sheets?

AAC (Autoclaved Aerated Concrete) panels are a lightweight and porous building material. Processing AAC panels usually requires a specially designed shredder to achieve effective crushing. According to the characteristics of AAC sheets, the following types of shredders are usually used:Double shaft shredderFeatures: The twin-shaft shredder has two rotating shafts and usually uses a high-torque, low-speed working method. It is suitable for processing hard and porous materials with high output.Advantages:…

Learn MoreIndustrial Solid Waste Disposed By Single-Shaft Shredder

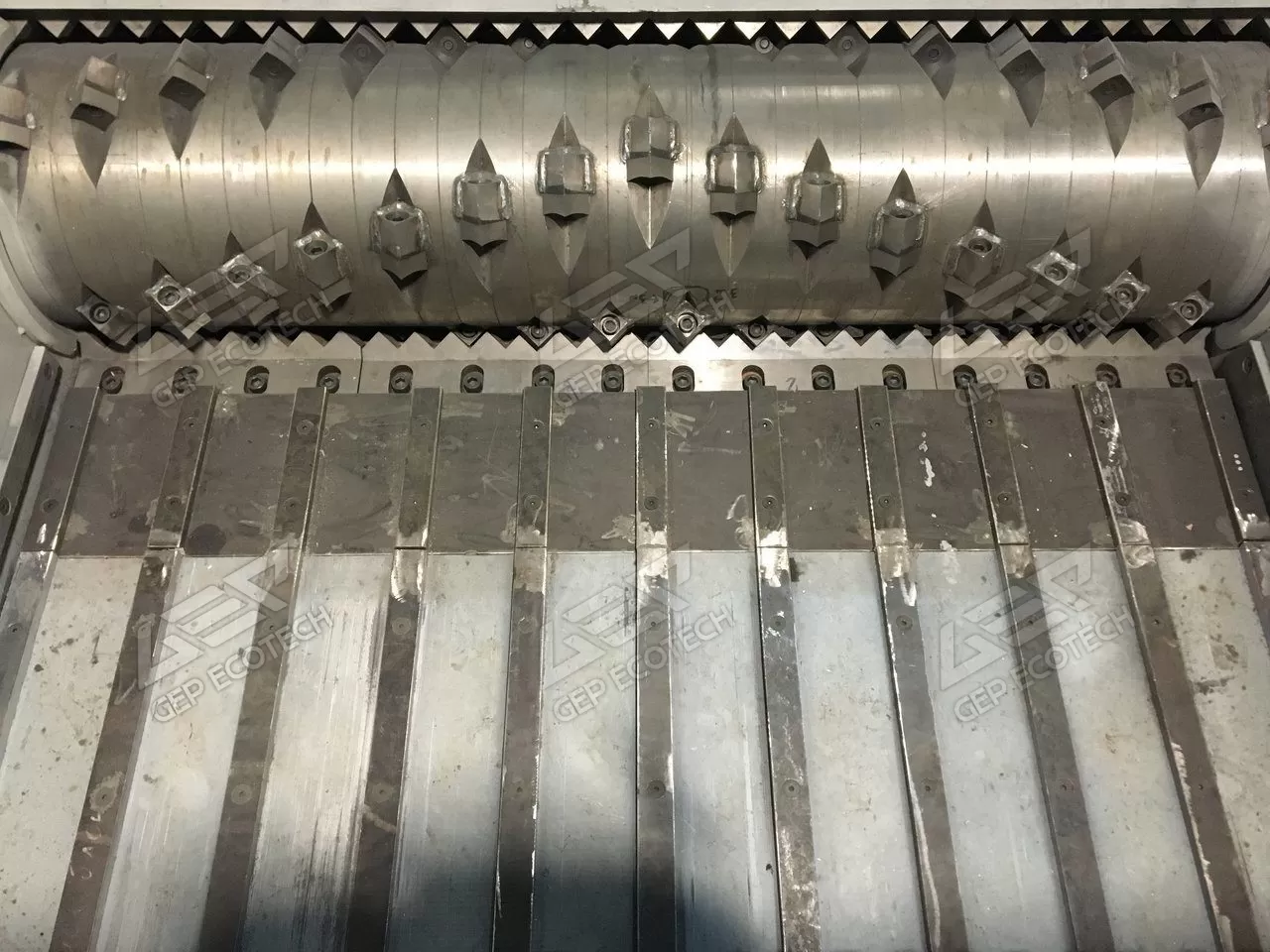

Single-shaft shredder has been widely used in general industrial solid waste disposal. It can effectively process flexible materials such as waste spinning, leather, waste paper, plastics, and wood, reduce the volume of materials, and facilitate further recycling at the back end.Single-shaft shredder working principleSingle-shaft shredder is the use of movable cutter and fixed cutter interaction, the material for shredding, cutting, extrusion processing to smaller particle size, and through the screen to…

Learn MoreCan a Single-Shaft Shredder Crush Battery Pole Pieces?

Single-shaft shredders can be used to shred battery pole pieces in many situations, but the success of the shredding depends on several key factors, including the material of the battery pole pieces, the performance of the machine and the blade design. This article will delve into the feasibility of crushing battery pole pieces with a single-shaft shredder, and also attaches a trial video of our factory to demonstrate the crushing effect.Properties of battery pole piecesBattery pole pieces are usually made…

Learn MorePlastic Shredding Machines for Sale in New Zealand

With the growing concern over plastic waste pollution and its impact on the environment, the demand for efficient plastic shredding solutions has surged worldwide. In response to this pressing need, GEP ECOTECH, a leading environmental technology company, offers state-of-the-art plastic shredding machines for sale in New Zealand. These cutting-edge machines are designed to handle various types of plastic waste and contribute to the reduction of plastic pollution while promoting a sustainable circular…

Learn More5 Ton per Hour Single Shaft Shredder for Industrial Waste to RDF Project

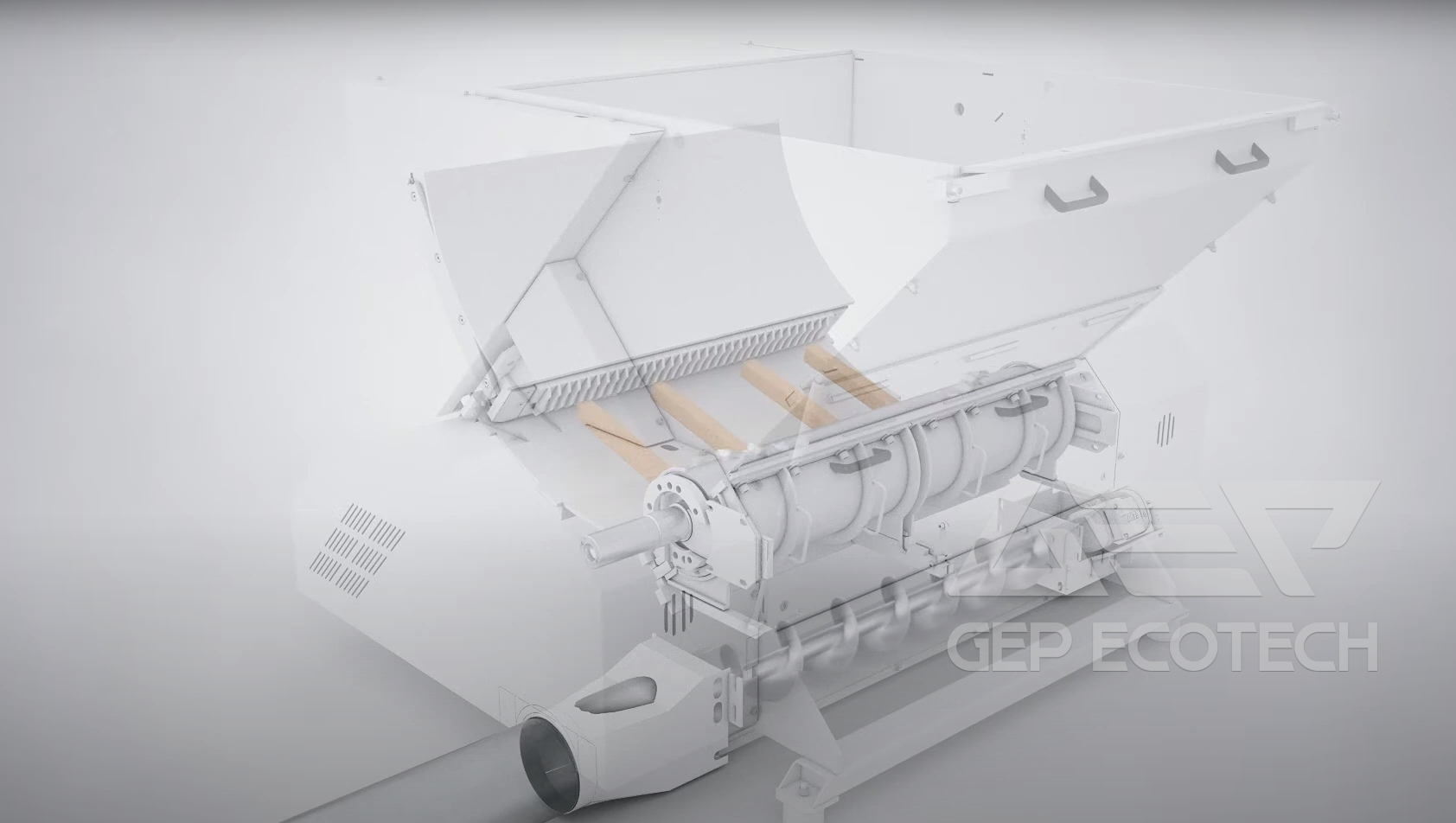

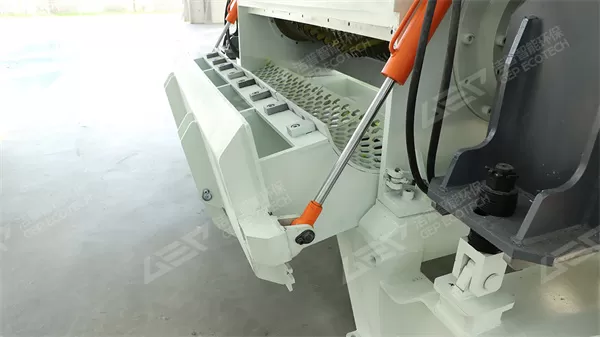

In the Zhejiang industrial waste to RDF project that was put into operation recently, we used the new third-generation single-shaft shredder optimized and upgraded by GEP, with a capacity of 5 tons per hour. This new single-shaft shredder has continuous high throughput and uniform output granularity, and can easily shred thick plastic pipes, twisted ropes, plastic bags, leather, waste clothes, etc. The strong wear-resistant structure is ideal choice for harsh recycling tasks. The new single-shaft shredder…

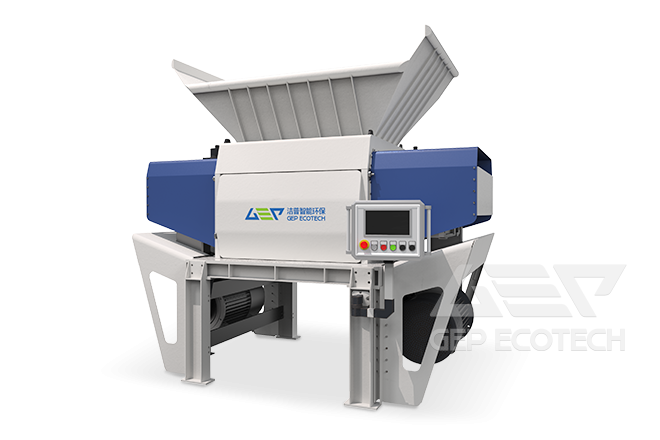

Learn More3rd Generation Fine Shredder

GSE-3 series European version single shaft fine shredder is the third generation enhanced product of GEP ECOTECH single shaft fine shredder series. It not only comprehensively adjusted the structure design, but also strengthened the equipment as a whole, making the equipment more widely applicable, with stronger shredding capacity, and better processing effect in high-intensity crushing operation of complex materials in large production lines.

Learn MoreGSE-3 Series European Version Fine Shredder Coming into Market with Honor

The European version fine shredder is a star product of GEP ECOTECH. With the increasing demand for fine finishing after more materials are recycled, the sales volume of it in the past two years has been close to that of the "Big Brother" -- double shaft shredder. It is a product which is frequently mentioned by name by solid waste treatment enterprises. According to the market demand, new application fields and customers' higher requirements for shredding capacity, the R&D engineers of GEP ECOTECH have…

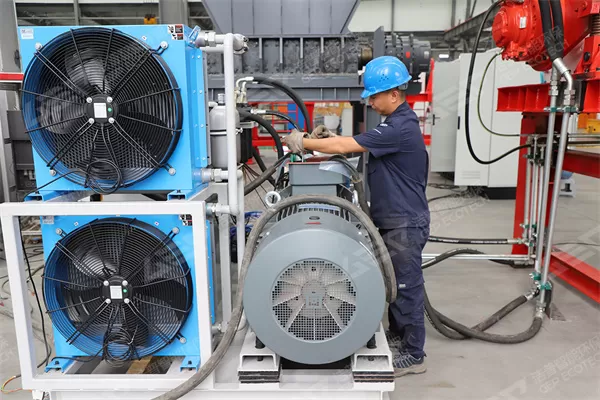

Learn MoreGEP ECOTECH Has a Steady Stream of Waste Disposal Equipment Orders

After a rainstorm, the sunshine weather was quickly restarted. No matter how changeable the weather is outside, the workshop of GEP ECOTECH is still busy.This is the GC series Pre-shredder shipped to Europe, which has already been loaded. This is the GD series Double-shaft shear shredder, GSS series European single-shaft shredder and GTS series trommel screen purchased by a North American customer, who will come to inspect the goods in a few days. Not long ago, the waste textile shredding sets and bulky…

Learn MoreWhen FRP Scrap Meets Shredder

FRP (Fiber Reinforced Plastics) is a composite material made of glass fibers and its products (glass cloth, tape, felt, yarn, etc.) as reinforcing material and synthetic resin as matrix material. Light and hard, non-conductive, corrosion-resistant, stable, high mechanical strength, can replace steel manufacturing machine parts and automotive, ship shells, etc., but less recycling.Based on one, the lifespan of FRP is 10-20 years and the trim waste generated during production is about 3%-5% of the output,…

Learn MoreSingle Shaft Shredder Unit China 35 KW for Industrial Waste Recycling

At the beginning of 2022, our customized 35 kw single-shaft shredder for industrial waste recycling in Shandong, China will be shipped on time, this equipment will be combined with double-shaft shredder, chain conveyor, belt conveyor, self-unloading iron remover, pulse dust collectors and other equipment together form a production line to provide assistance for the treatment of industrial waste such as glass fiber reinforced plastics. Our 35 kw single-shaft shredder is used for secondary shredding in the…

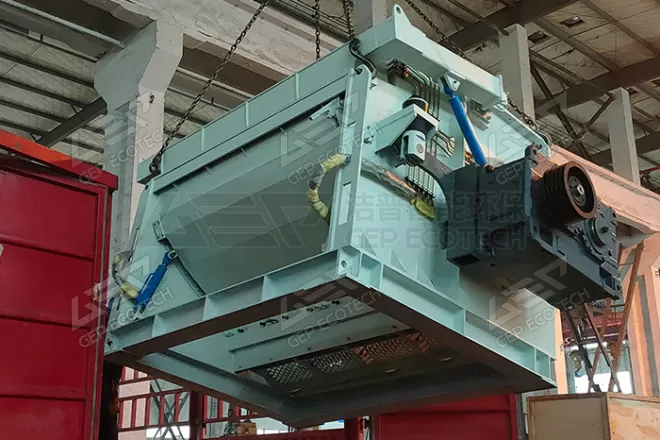

Learn MoreWind and Snow, Set Off on Time

Last weekend, the production staff of GEP ECOTECH worked overtime in spite of the snow, Shandong FRP shredding and disposal equipment and Jiangxi bulky waste shredding and disposal equipment were loaded and shipped one after another and departed on time. This is also a successful conclusion to the Year of the Ox.Apart from the classic production line equipment such as double shaft shredder, chain conveyor, belt conveyor, self-unloading iron remover, pulse dust collector and intelligent centralized control…

Learn MoreSingle-Shaft Shredder Is a Better Choice for Crushing Copper Wires

Copper wire crusher is also called copper wire shredder. Copper wire crusher is a kind of pretreatment equipment for separating and shredding old wires, cables, and waste copper wires. It can solve the problem of old wires, cables, and copper wires occupying space and resources and causing serious pollution to the environment. The crusher can well shred electronic waste such as copper wires, waste cables, USB data cables, and automobile cables into 10-120mm granularity for use in copper sorting operations…

Learn MoreIndustrial plastic shredder machine for sale

Industrial waste plastic refers to the waste plastic products after industrial production. At present, our government strongly supports various places to do a good job in waste separation and recycling projects, while waste plastic is a common waste in our daily life, so its available line is very good, but also easy to recycle. Therefore, more and more people have started to engage in this industry.How can our recycled industrial plastic waste be turned into treasure?First we must know that the recycled…

Learn MoreSingle shaft shredder for PE plastic film

Improper disposal of waste pe films will cause harm to the environment. Landfilling is not a long-term solution, because the current degradation cycle of plastics is generally at least 200 years. Plastic film recycling really makes a lot of sense. Some plastic film recycling machines, such as single shaft shredder for pe film, can help make the entire recycling easier.What are the sources of waste PE plastic film?PE plastic film is a flexible plastic with a wide range of uses, such as shopping bags,…

Learn MoreHow to treat film plastic bags (linear low density polyethylene) with a single shaft shredder

Low density polyethylene, also known as high pressure polyethylene (LDPE), is the lightest variety of polyethylene resin, milky white, tasteless, odourless, non-toxic, wax-like particles with a lustreless surface. It has good flexibility, extensibility, electrical insulation, transparency, ease of processing and a certain degree of permeability. It is chemically stable and resistant to alkalis and organic solvents.Application range of LDPE:Suitable for food packaging such as seasoning, pastry, sugar,…

Learn MoreSingle-Shaft Shredder with Pressure Mechanism

The single-shaft shredder is a machine used to finely shred materials. It is used for recycling. The most common materials for shredding on a single-shaft shredder are fibrous, such as: plastic, paper, textiles, wood, polymers, microcircuits boards and other waste.Working Principle of the Single-shaft ShredderThe processed material is fed into the receiving hopper, which is installed on the shredder's support frame. The raw materials to the bunker can be carried out both manually and mechanically. The…

Learn MoreCase study of a single shaft shredder for domestic waste disposal

Domestic waste treatment refers to the treatment of solid waste generated from daily life or activities providing services for daily life, as well as solid waste considered to be domestic waste as defined by law and regulations, including source reduction, cleaning, separate collection, storage, transport, treatment, disposal and related management activities of domestic waste. The aim of treatment is to reduce the amount of waste produced and to make the "quality" (composition and characteristics) and "…

Learn MoreSingle Shaft Shredder for MSW, Plastic, Paper

Single-shaft shredders have been designed for a wide range of applications in both domestic and industrial recycling. Depending on the purpose, single-shaft shredders can be used directly as stand-alone machines or as part of a line for subsequent or primary shredding of material.ApplicationPaper, corrugated cardboard, archival documents;Wood waste, wooden boxes, pallets, laminated chipboard, fiberboard;Plastic, bulk polymer containers, sprues, polycarbonate, HDPE, PET, PP, ABS, EVA, PVC;Electronic…

Learn MoreDouble Rotor Fine Shredder

GSD is a powerful high-standard fine shredder that can quickly shred materials to the required shape and size. GSD uses dual rotors to shred materials, which is more efficient and has a larger production capacity.

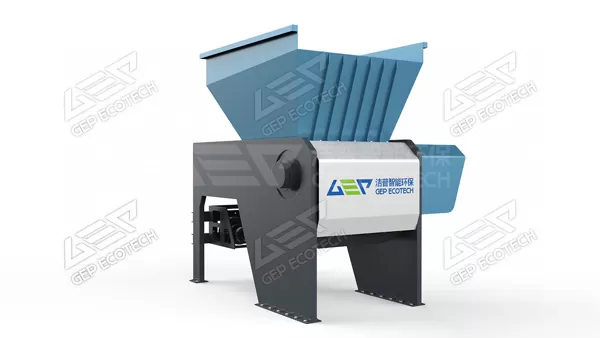

Learn MoreSingle Rotor Fine Shredder

The GSS series single rotor shredder is suitable for processing a wide range of materials to a small and uniform size, with a maximum capacity of around 1 - 20 tons per hour and a discharge size of 30 to 120 mm, depending on the model of the machine, the type of material, the size of the screen and the field of application.

Learn MoreDifference Between Single Shaft Shredder and Double Shaft Shredder

For the customers who are new to the shredder, most of them will not distinguish the difference between the single shaft shredder and the double shaft shredder. The difference between a single-shaft shredder and a double-shaft shredder can be roughly understood by the equipment name, that is, a single-shaft shredder is a device that realizes material tearing and crushing through one main shaft, while a double-shaft shredder uses two main shaft realizes material crushing and processing.Let us take a look at…

Learn MoreHow to choose a single-shaft shredder

There are a lot of different materials in the market and many plastic boxes for domestic waste. In addition to the double shaft shearing type crusher, the single-shaft shredder can also be used. So how to choose? Today, GEP ECOTECH takes you to know.GSS series single-shaft shredder is a new upgraded fine crusher, which adopts single shaft "motor + reducer" drive design to provide large shear force and ensure high crushing efficiency. It is widely used in the fields of resource regeneration, RDF (domestic…

Learn MoreSingle Shaft Shredder How Much They Cost

Whether it is the secondary crushing of fuel derived from domestic waste, fine plastic crushing, domestic waste crushing and other fields, the disposal efficiency of the single-shaft shredder is leveraged! So single shaft shredder how much they cost? Today, the editor will popularize the factors that affect the price of single shaft shredder.1. Materials to be shred: including size, ingredients, etc.The solid waste is very mixed. The crushing strength of single shaft shredder with different strengths is…

Learn More