The European version fine shredder is a star product of GEP ECOTECH. With the increasing demand for fine finishing after more materials are recycled, the sales volume of it in the past two years has been close to that of the "Big Brother" -- double shaft shredder. It is a product which is frequently mentioned by name by solid waste treatment enterprises. According to the market demand, new application fields and customers' higher requirements for shredding capacity, the R&D engineers of GEP ECOTECH have carried out all-round optimization and upgrading in such aspects as design, performance, quality, experience, etc. on the basis of the GSS series European version fine shredder, and grandly launched the third generation GSE-3 series European version fine shredder.

What are the advantages of GSE-3 series European version fine shredder? Let's find them out:

High Integrity

The power system, shredding system, hydraulic feeding system, rapid discharging system, intelligent protection system and maintenance system are integrated to make operation more convenient and automatic processing capability and collaboration function more powerful.

Original Advantages Strengthening

The original oblique push hydraulic booster, "V" type cutter layout and fixed mode are completely retained. With the new equipment structure, advantages and functions are displayed to a greater extent, and the equipment has higher crushing capacity and effect.

Better Equipment Structure

The blanking screen and the access door are integrated, which reduces some auxiliary components. When the equipment is being maintained, it can be opened hydraulically with one button. It is more convenient to overhaul and adjust the screen, which not only shortens the maintenance time, but also greatly improves the stability of the long-term operation of the equipment.

Basic Function Upgrading

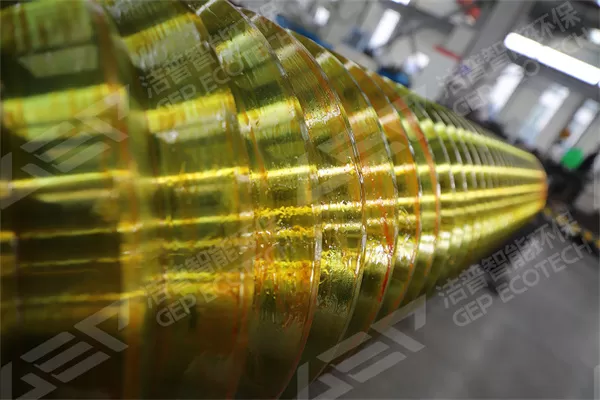

The wear-resistant layer is added to the cutter shaft, and the toughness and strength ratio of the cutter are adjusted, so that the basic functions of the equipment can play a higher crushing capacity and efficiency under the new structure. The performance is comprehensively improved, the equipment has a wider scope of application, and the service life is longer.

Automation and Intelligence Improving

The new equipment has strong integration. Three upgrades have made all functions more compatible with the GI intelligent monitoring system of GEP ECOTECH. The degree of equipment automation has been further improved, and automatic maintenance, data monitoring, exception handling and other aspects are more intelligent.

More Thoughtful Design

The protective cover of the belt conveyor is changed into a divided structure, which not only makes it easier to disassemble and replace the belt, but also makes the transmission components more ventilated, which can effectively prevent dust accumulation and improve the stability of equipment operation; The appearance of the equipment is exquisite, and a variety of colors can be matched to add color to the workshops of different styles.

In addition, in terms of production and processing that users are particularly concerned about, relying on the high-precision equipment processing system of the intelligent equipment production base, the whole process from steel plate cutting, grinding, bending, planing, milling to painting has achieved digital control, with fast processing speed, high processing accuracy, stable and reliable quality, and users are more relieved to use.

The third generation European version fine shredder further meets the needs of users, especially domestic municipal solid waste and industrial waste disposal users, for high-intensity crushing operation of complex materials in large production lines. It will certainly win the trust and favor of more users with a wider scope of application, stronger crushing capacity and more comprehensive performance.