Machine to Finely Shred Wood & Tree Branches

Earlier this year, GEP ECOTECH's technical team visited a biomass processing facility in Southeast Asia to follow up on a GXB series fine shredder installed just over one years ago. This particular machine was configured for reducing tree branches, wood offcuts, and agricultural waste into uniform fine particles—an essential step in biomass fuel production.We spoke with Mr. Surya, the plant manager overseeing daily operations.“We run this shredder nearly every day—processing anything from fresh-cut…

Learn MoreGXB Biomass Sherdder: Sherdding Problem, Solved With One Machine!

Efficient shredding, precise discharge, and holding of complex materials!GXB biomass sherdder, specially designed for the resource utilization and disposal of various types of biomassEasily handle material handling capacities ranging from 3.5 to 16 tons/hourDischarge fineness

Learn MoreBiomass Fine Shredder

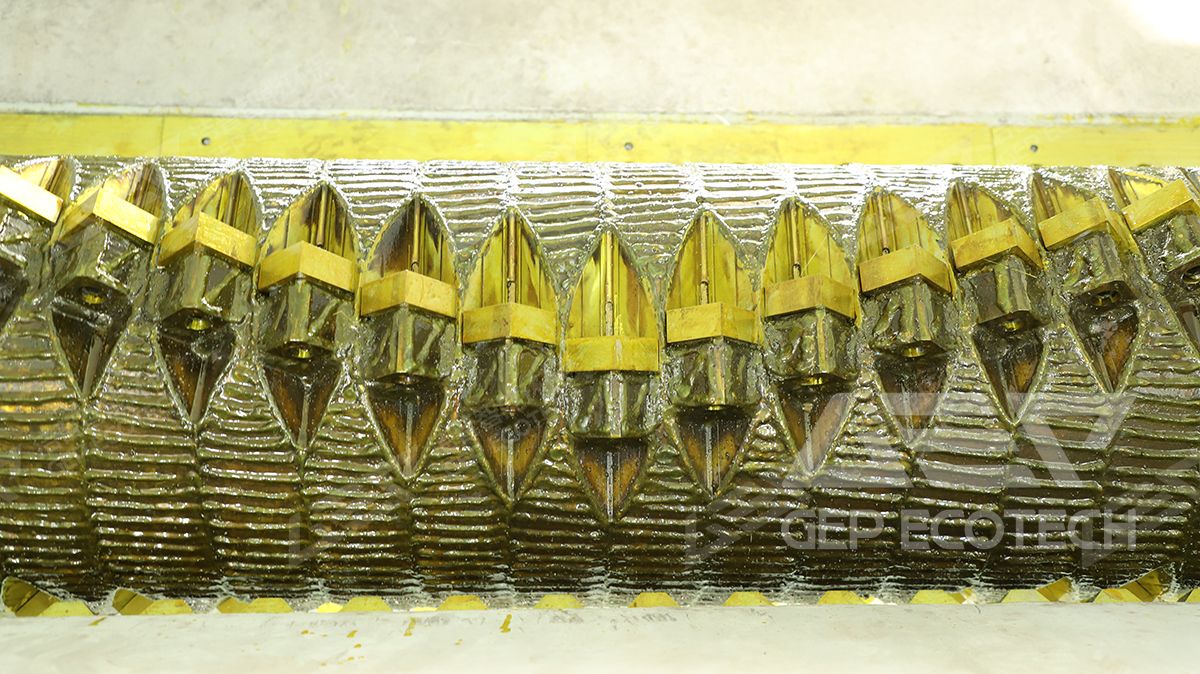

The GXB biomass fine shredder is specially designed for the fine shredding stage in biomass recycling lines. It features a large-diameter rotor to increase linear velocity and rotational inertia and a large, adjustable screen area ensures effective material discharge and precise particle size control, significantly improving shredding efficiency and output consistency.

Learn MoreSolving Key Problems in the Preparation of Waste Textile Fuel

In order to cope with energy cost pressure and reduce carbon emissions, many cement companies are actively looking for alternatives to coal-fired power generation. Waste textiles, with their advantages of considerable calorific value (average calorific value of about 4300kcal), high volatile matter, low ash content, low moisture content, and low emissions of harmful substances, have become the ideal alternative fuel for cement companies to compete for.In response to this market demand, GEP has meticulously…

Learn MoreWhy Use a Fine Shredder As Secondary Process for Processing Alternative Fuels

In recent years, twin-shaft shredders have garnered widespread recognition as primary shredders in solid waste crushing applications. However, single-shaft shredders hold a distinct advantage over their double-shaft counterparts in their ability to process materials into finer sizes. Consequently, single-shaft shredders are frequently deployed as fine shredders for secondary crushing following double-shaft shredders. This is particularly evident in the realm of alternative fuel processing, where single-…

Learn MoreShred Polyurethane Foam Waste and Obtain a Fine Granulation

Polyurethane foam waste, known for its resilience and durability, has posed challenges in effective waste management. However, with the advent of advanced shredding technologies, it is now possible to efficiently shred polyurethane foam waste and obtain fine granulation. This article delves into the equipment crucial for shredding polyurethane foam waste and explores the diverse applications of the resulting fine granules.Advanced Shredding Equipment for Polyurethane Foam WastePolyurethane foam, ubiquitous…

Learn MoreUnveiling the GEP ECOTECH Shredder's Popularity in Cement Kiln Alternative Fuel Pretreatment

In the cement industry, alternative fuels refer to those that can replace traditional fossil fuels, including biomass alternative fuels and non biomass alternative fuels. These alternative fuels are usually prepared from combustible waste, such as waste tires, household waste, industrial waste, straw, waste oil, tar, garbage biogas, etc.At present, most cement enterprises use cement kiln collaborative disposal production lines to produce alternative fuels with low pre-treatment and disposal quality,…

Learn MoreEfficient Ways to Recycle Fan Blades: Sustainable Disposal Solutions

Wind power generation, as a representative of clean energy, has been developing rapidly. The design life of wind turbines is approximately 20-25 years, and a large number of wind turbines are retired every year. The valuable parts of wind turbines for recycling include towers, bases, engine covers, blades, etc. Among them, 85% -90% of scrapped materials have mature recycling systems, but the recycling mode of fan blades is still being explored. The widely used fan blade materials are composed of…

Learn MoreFine Shredder for Rice Straw Shredding

Fine shredders for rice straw shredding are specialized machines designed to break down rice straw into smaller, fine particles for various applications. Here are details regarding the types of fine shredders and the uses of shredded rice straw:Types of Fine Shredders for Rice Straw ShreddingSingle Shaft Fine Shredders: These machines feature a single shaft with sharp blades or cutters for finely chopping and shredding rice straw into smaller pieces. They are efficient and commonly used for various…

Learn MoreGEP ECOTECH Core Equipment Shredder Chapter

Relying on GEP ECOTECH's strong R&D and manufacturing capabilities and rich project operation experience, the GEP ECOTECH's shredder has won widespread recognition in the market.Double-shaft shredderDouble-shaft shredder is a universal solid waste shredding equipment that utilizes cutting and tearing methods to reduce material size. The main advantage of the double-shaft shredder comes from its low speed and high torque driving method, which provides large shear force for garbage disposal applications…

Learn MoreTechnology of Coordinated Disposal of Solid Waste in Cement Kilns

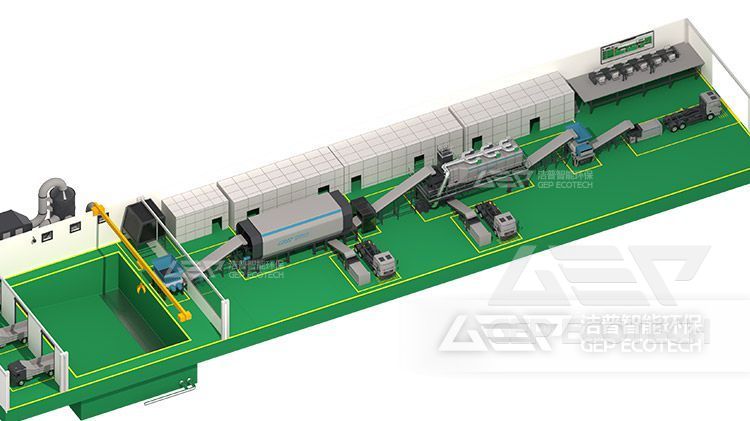

The technology of cement kiln collaborative disposal of household garbage relies on the original decomposition furnace, rotary kiln and other high-temperature kilns of the new dry pre-decomposition clink production line to realize the reduction, resource and harmless of household garbage. Due to its high disposal efficiency, less investment, short construction period, thorough disposal of harmlessly, good environmental protection indicators and other advantages, it has been more and more widely used.The…

Learn More3rd Generation Fine Shredder

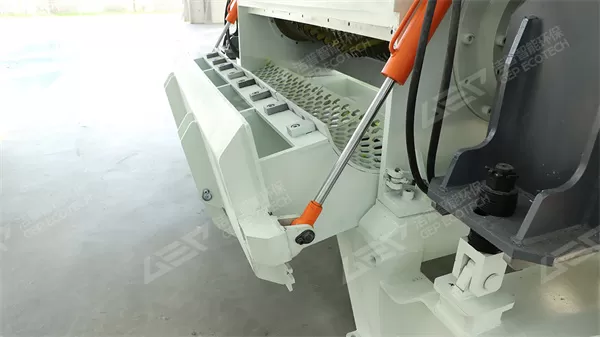

GSE-3 series European version single shaft fine shredder is the third generation enhanced product of GEP ECOTECH single shaft fine shredder series. It not only comprehensively adjusted the structure design, but also strengthened the equipment as a whole, making the equipment more widely applicable, with stronger crushing capacity, and better processing effect in high-intensity crushing operation of complex materials in large production lines.

Learn MoreGSE-3 Series European Version Fine Shredder Coming into Market with Honor

The European version fine shredder is a star product of GEP ECOTECH. With the increasing demand for fine finishing after more materials are recycled, the sales volume of it in the past two years has been close to that of the "Big Brother" -- double shaft shredder. It is a product which is frequently mentioned by name by solid waste treatment enterprises. According to the market demand, new application fields and customers' higher requirements for shredding capacity, the R&D engineers of GEP ECOTECH have…

Learn MoreDouble Rotor Fine Shredder

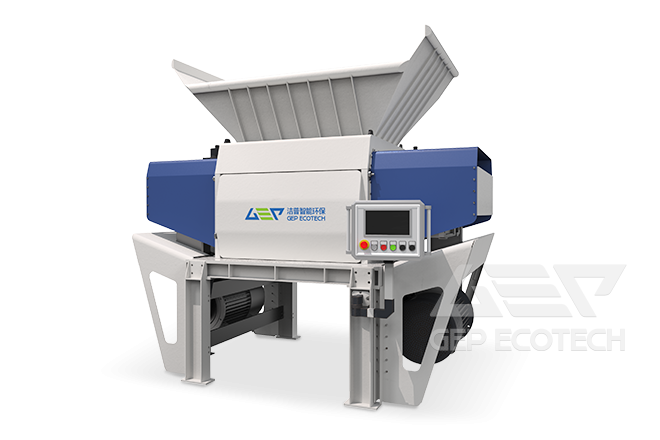

GSD is a powerful high-standard fine shredder that can quickly shred materials to the required shape and size. GSD uses dual rotors to shred materials, which is more efficient and has a larger production capacity.

Learn MoreSingle Rotor Fine Shredder

The GSS series single rotor shredder is suitable for processing a wide range of materials to a small and uniform size, with a maximum capacity of around 1 - 20 tons per hour and a discharge size of 30 to 120 mm, depending on the model of the machine, the type of material, the size of the screen and the field of application.

Learn MoreSingle Shaft Shredder How Much They Cost

Whether it is the secondary crushing of fuel derived from domestic waste, fine plastic crushing, domestic waste crushing and other fields, the disposal efficiency of the single-shaft shredder is leveraged! So single shaft shredder how much they cost? Today, the editor will popularize the factors that affect the price of single shaft shredder.1. Materials to be shred: including size, ingredients, etc.The solid waste is very mixed. The crushing strength of single shaft shredder with different strengths is…

Learn More