In the cement industry, alternative fuels refer to those that can replace traditional fossil fuels, including biomass alternative fuels and non biomass alternative fuels. These alternative fuels are usually prepared from combustible waste, such as waste tires, household waste, industrial waste, straw, waste oil, tar, garbage biogas, etc.

At present, most cement enterprises use cement kiln collaborative disposal production lines to produce alternative fuels with low pre-treatment and disposal quality, resulting in large fluctuations in the calorific value of the produced alternative fuels, which has a significant impact on the operation of cement clinker production lines. Therefore, improving the manufacturing level of raw material pretreatment equipment for alternative fuels has become crucial.

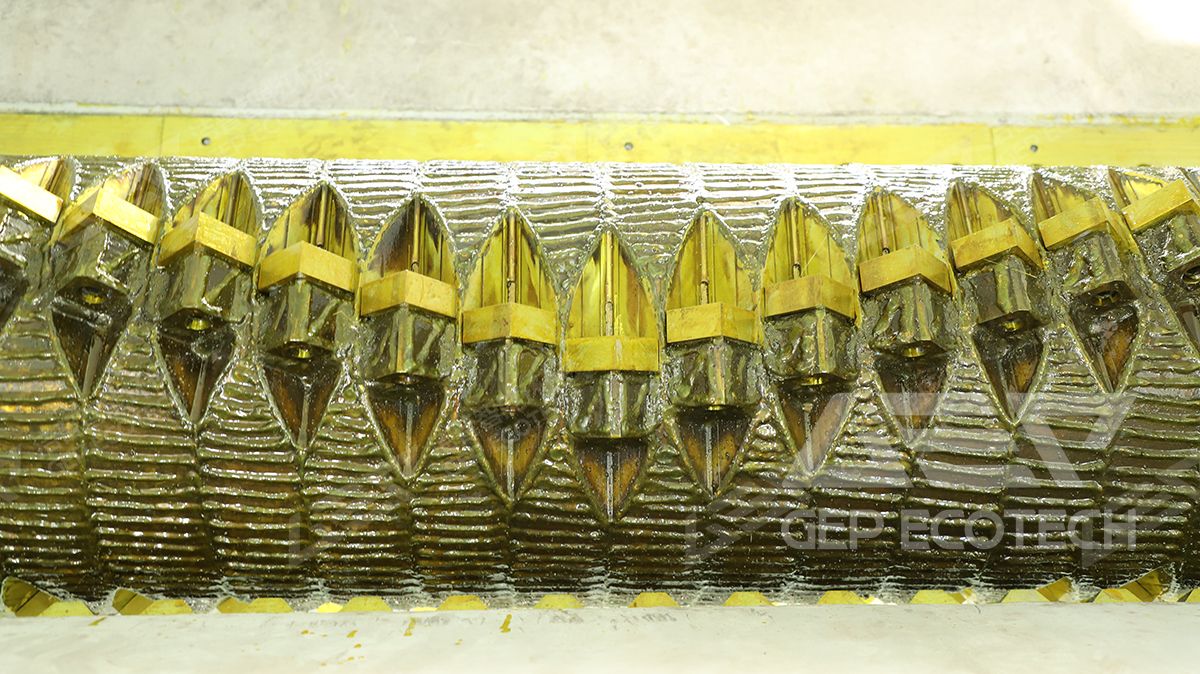

GEP ECOTECH has performed excellently in this area. A dedicated double-shaft shredder has been developed for different raw materials, such as waste tires, straw, and industrial waste. In order to achieve smaller dimensions, optional equipment such as single rotor fine shredder, double rotor fine shredder, and four-shaft shredder are also provided.

The cutting tools of these shredders are made of high alloy steel material and processed through multiple processes, with higher accuracy and stability. The spindle is made of high alloy steel material, which undergoes two heat treatments and forging quenching and tempering, and is then processed by high-precision CNC machine tools for turning and milling. The transmission part adopts a more precise spline structure, which makes the force more uniform and the guidance better. The integral knife box adopts overall annealing treatment to avoid pre stress caused by welding, with higher mechanical strength, less deformation during long-term use, and longer service life.

In addition, GEP ECOTECH's shredder adopts a five fold sealing structure in terms of sealing, including mechanical structure, labyrinth structure, oil seal, etc., achieving waterproof, dustproof, and anti fouling effects. In terms of lubrication methods, a centralized lubrication system is adopted, which can regularly and quantitatively lubricate various lubrication points of the equipment. This not only avoids component failure and damage caused by poor lubrication, but also improves the safety and automation level of the equipment. In terms of control mode, an intelligent control system composed of PLC and HMI is adopted, which has protection functions such as short circuit, overload, and leakage, as well as temperature monitoring, current monitoring, fault and operation record query in manual and automatic modes.

Overall, GEP ECOTECH's alternative fuel raw material pretreatment equipment has played an important role in improving fuel substitution technology in the cement industry. Welcome everyone to inquire and purchase!