5 Ton/Hour Slaughterhouse Waste Double Shaft Shredder Shipped to Philippines

This week, a customized 5 ton/hour double shaft shredder for slaughterhouse waste was successfully packed and shipped to the Philippines.The Filipino client operates a large-scale slaughterhouse and rendering facility. Their goal: to not only meet environmental standards but to repurpose organic waste into energy through anaerobic digestion. For the biogas plant to work efficiently, the input material — which includes bones, entrails, meat scraps, and fat — must be uniformly reduced to 20mm or smaller, the…

Learn MoreIndustrial Plastic Waste Shredder Specifications

Industrial plastic waste shredders are essential for processing and recycling various types of plastic waste, such as packaging materials, pipes, bottles, and production scraps. These shredders come in different configurations—single-shaft, double-shaft, and four-shaft—each tailored for specific applications and material requirements.The following article will list the main features and specifications of these shredders to help you quickly find the right equipment for your project.Single-Shaft Plastic…

Learn MoreSingle Shaft vs. Double Shaft PVC Shredder Machine

PVC shredders play a crucial role in recycling and waste management by breaking down PVC materials into smaller, manageable pieces for further processing. These shredders come in two main configurations: single shaft and double shaft. Both types serve different purposes depending on the material’s nature and the desired output.Single Shaft PVC ShredderA single shaft shredder has a rotor with sharp cutting blades and a stationary screen, through which the shredded material passes once it reaches the desired…

Learn MoreRotary Shear Shredder for Sale

Today, a customer consulted about equipment for shredding urban mixed garbage. After comprehensive consideration, we recommended a rotary shear shredder. Since the customer has just entered the field of solid waste disposal and has little knowledge of this equipment, let us briefly learn about this equipment:What is a Rotary Shear Shredder?A rotary shear shredder is a commonly used machine in the solid waste processing industry. It operates based on the principle of "cutting and shearing," effectively…

Learn MoreShredders for Steel Swarf: Single-Shaft vs. Dual-Shaft

Steel swarf, the metal chips and shavings from machining, needs effective processing for recycling and waste management. Single-shaft and dual-shaft shredders are commonly used, each with distinct characteristics related to throughput and output size.Single-Shaft ShreddersFeatures:Design: One rotating shaft with blades.Throughput: Typically lower capacity compared to dual-shaft shredders.Output Size: Produces uniformly sized output, ideal for applications needing consistent particle size.Benefits:Cost-…

Learn MoreIndustrial Shredders in Converting Waste to Fuel

As industries strive to address environmental challenges and enhance sustainability, converting waste into fuel has emerged as a significant solution. Industrial shredders play a pivotal role in this process by preparing waste materials for transformation into valuable energy sources. This article examines the function of industrial shredders in waste-to-fuel projects and explores the types of shredders commonly used in these applications.Role of Industrial Shredders in Waste-to-Fuel ProjectsIndustrial…

Learn MoreSingle Shaft Biomass Shredder vs. Dual Shaft Biomass Shredder

When it comes to processing biomass, selecting the appropriate shredder can significantly impact the efficiency and quality of the operation. Single shaft and dual shaft shredders are two commonly used technologies, each offering distinct advantages depending on the specific requirements of the task. This article explores the key differences between single shaft and dual shaft biomass shredders, focusing on aspects such as output, particle size, and operating modes.1. OutputSingle Shaft Shredder:Single…

Learn MoreDouble Shaft Shredder and Wood Chipper for Biomass Processing

When it comes to biomass processing, two critical pieces of equipment are the double shaft shredder and the wood chipper. Both serve unique purposes and offer distinct advantages, making them essential for different aspects of wood and biomass waste management. This article explores the differences between these two machines, covering their features, suitable materials, and production capacities.Double Shaft ShredderFeatures:Design: The double shaft shredder consists of two parallel rotating shafts with…

Learn MoreSolving Key Problems in the Preparation of Waste Textile Fuel

In order to cope with energy cost pressure and reduce carbon emissions, many cement companies are actively looking for alternatives to coal-fired power generation. Waste textiles, with their advantages of considerable calorific value (average calorific value of about 4300kcal), high volatile matter, low ash content, low moisture content, and low emissions of harmful substances, have become the ideal alternative fuel for cement companies to compete for.In response to this market demand, GEP has meticulously…

Learn MoreDouble Shaft Shredder Size 1200mm: An Overview

The 1200mm double shaft shredder is a versatile and robust machine designed for efficient shredding of various types of waste. This shredder is particularly suitable for managing large volumes of industrial waste, municipal solid waste (MSW), and other types of solid waste. Its design and functionality make it a critical component in waste management and recycling operations.Technical SpecificationsShredding Chamber Size: 1200 mm x 800 mmMotor Power: Typically 2 x 22 kW or equivalent, depending on specific…

Learn MoreProcessing Textile Scrap to Size Reduce With Double Shaft Shredder

In textile scrap processing, the utilization of double shaft shredders has revolutionized waste management practices. These machines offer versatility and efficiency, making them indispensable for size reduction in textile recycling operations. Here, we delve into the professional application of double shaft shredders, accompanied by real-world case studies showcasing their effectiveness. Key Advantages of Double Shaft ShreddersVersatility: Double shaft shredders effectively process a wide range of textile…

Learn MoreTwin Shaft Shredder to Cut 10MM Thick Copper Plates

The GDI twin shaft shredder is a specialized machine designed to efficiently cut through 10mm thick copper plates with precision and ease. Its dual shaft configuration ensures uniform shredding, breaking down the copper plates into smaller, manageable pieces for recycling or further processing. With its robust construction and powerful cutting mechanism, the twin shaft shredder offers a reliable solution for industries involved in copper scrap recycling, providing enhanced productivity and cost-…

Learn MoreDouble Shaft Shredder to Process the Pulper Ropes

This heavy-duty double shaft shredder is purpose-built to efficiently process pulper ropes, effortlessly reducing their density and tough composition. With razor-sharp blades driven by high-torque motors, it delivers consistent shredding performance, while its durable construction ensures reliable operation in industrial settings. Equipped with safety features and customizable configurations, this shredder offers versatility and safety, making it an ideal solution for waste management and recycling…

Learn MoreCarbon Emission Quotas to Be Released, Time to Learn More About Alternative Fuel Processing Equipment

According to the Chinese government website, the Provisional Regulations on the Management of Carbon Emission Trading will be implemented from May 1, 2024. The ecological and environmental management department of the State Council will work with relevant departments to formulate the total amount and distribution plan of annual carbon emission quotas. The provincial ecological and environmental management department, in conjunction with relevant departments at the same level, will distribute carbon…

Learn MoreUnveiling the GEP ECOTECH Shredder's Popularity in Cement Kiln Alternative Fuel Pretreatment

In the cement industry, alternative fuels refer to those that can replace traditional fossil fuels, including biomass alternative fuels and non biomass alternative fuels. These alternative fuels are usually prepared from combustible waste, such as waste tires, household waste, industrial waste, straw, waste oil, tar, garbage biogas, etc.At present, most cement enterprises use cement kiln collaborative disposal production lines to produce alternative fuels with low pre-treatment and disposal quality,…

Learn MoreYou Must Know About the Hydraulic Version in Double-Shaft Shredders

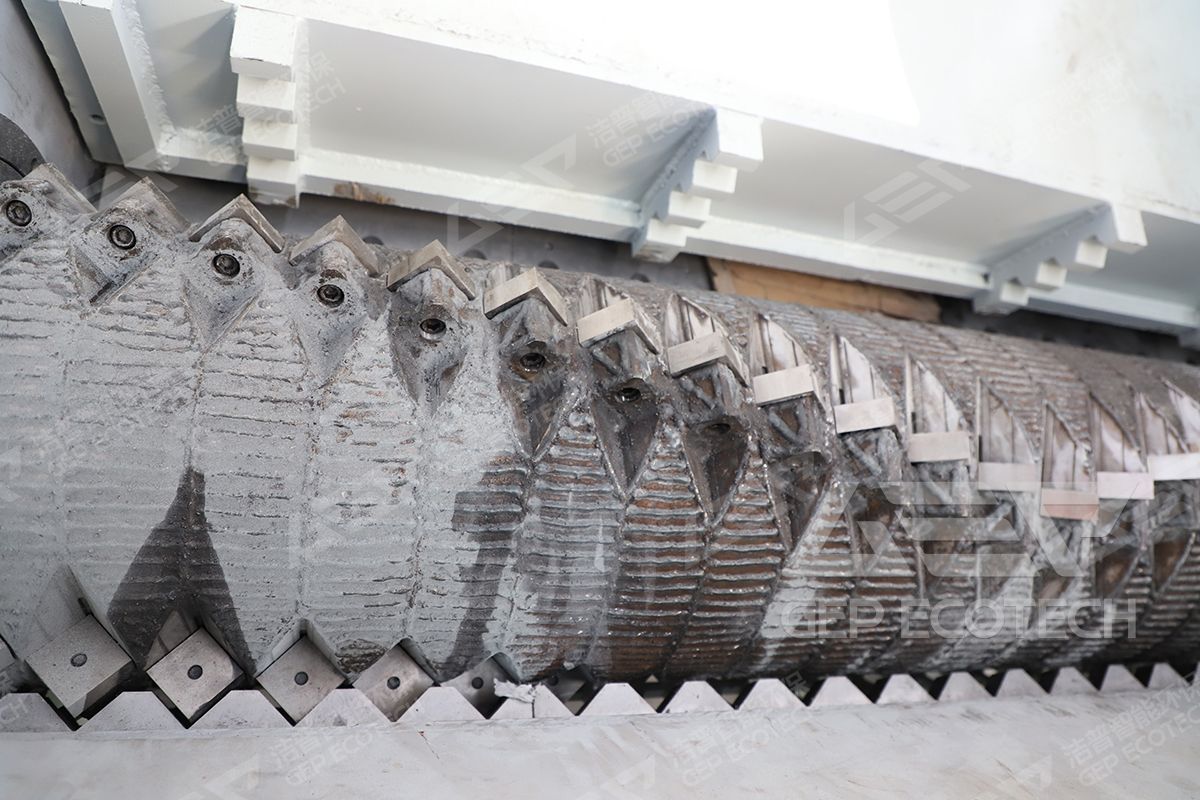

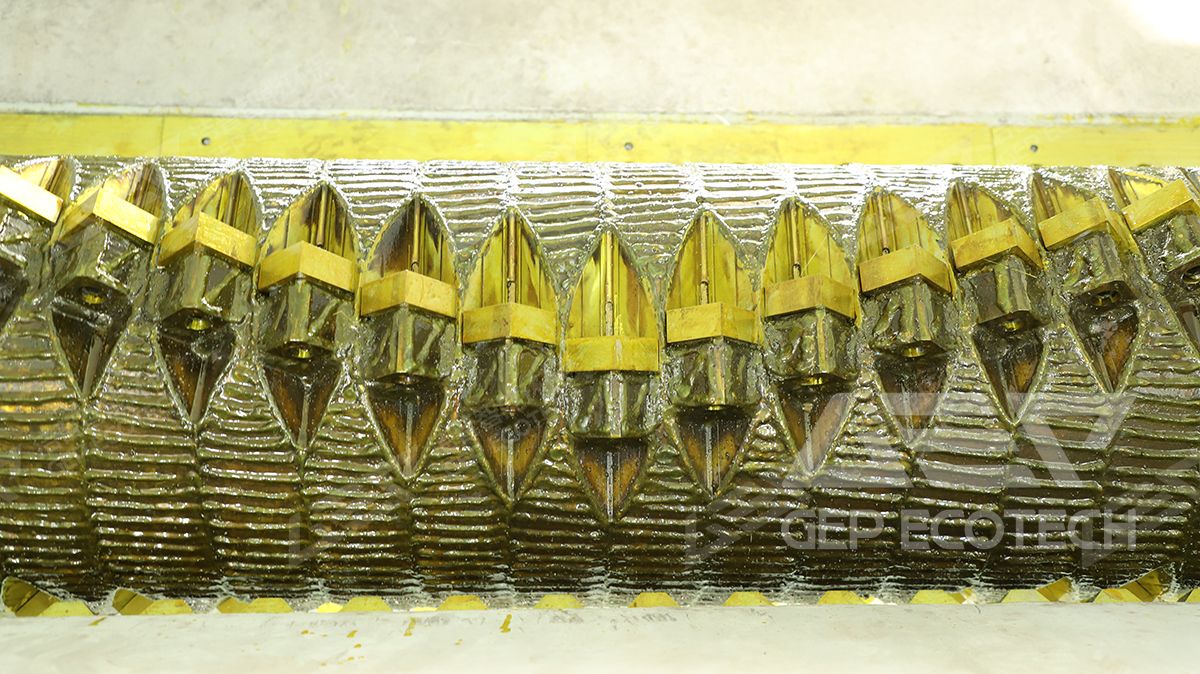

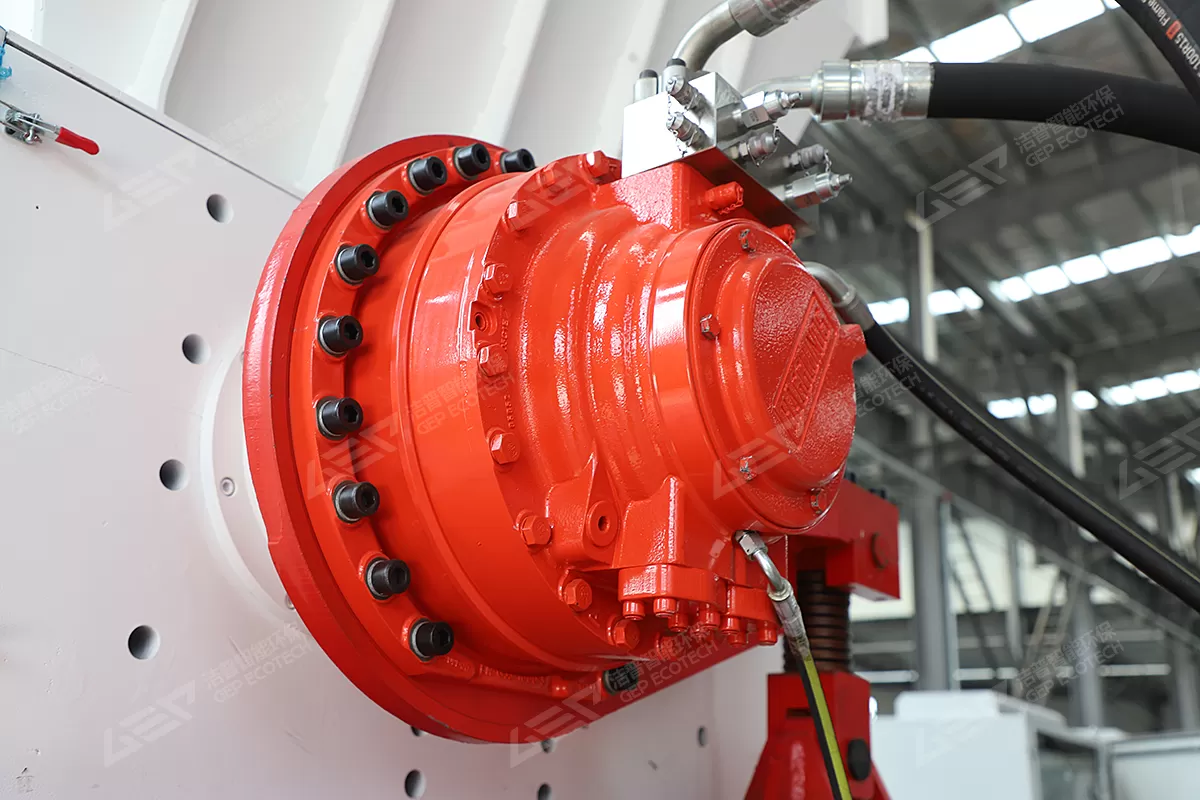

Introduction:The hydraulic version of the double-shaft shredder adopts dual rotors and dual hydraulic motors for drive. Each rotor is equipped with circular blades with teeth, and the two rotors rotate in opposite directions with different speeds. The material is crushed through the shearing and squeezing between the edges of the blade, as well as the tearing effect between the blade teeth. Its crushing capacity mainly depends on the structure of the shredder (blade diameter, blade overlap size, rotor…

Learn MoreEfficient Ways to Recycle Fan Blades: Sustainable Disposal Solutions

Wind power generation, as a representative of clean energy, has been developing rapidly. The design life of wind turbines is approximately 20-25 years, and a large number of wind turbines are retired every year. The valuable parts of wind turbines for recycling include towers, bases, engine covers, blades, etc. Among them, 85% -90% of scrapped materials have mature recycling systems, but the recycling mode of fan blades is still being explored. The widely used fan blade materials are composed of…

Learn MoreWhat Kind of Shredder Is Used for Crushing AAC Sheets?

AAC (Autoclaved Aerated Concrete) panels are a lightweight and porous building material. Processing AAC panels usually requires a specially designed shredder to achieve effective crushing. According to the characteristics of AAC sheets, the following types of shredders are usually used:Double shaft shredderFeatures: The twin-shaft shredder has two rotating shafts and usually uses a high-torque, low-speed working method. It is suitable for processing hard and porous materials with high output.Advantages:…

Learn MoreHow to Dispose of Rock Wool Waste?

Rock wool is a product made mainly of high-quality basalt, dolomite, and other raw materials, with an appropriate amount of binders and additives added. It is manufactured under high temperature and pressure and can be made into felt, strip, tube, granular, plate and other forms according to different purposes. It is used in industrial, construction, shipbuilding, and agricultural fields such as nuclear power plants, power plants, large kilns, external insulation of building walls, isolation belts, cabins…

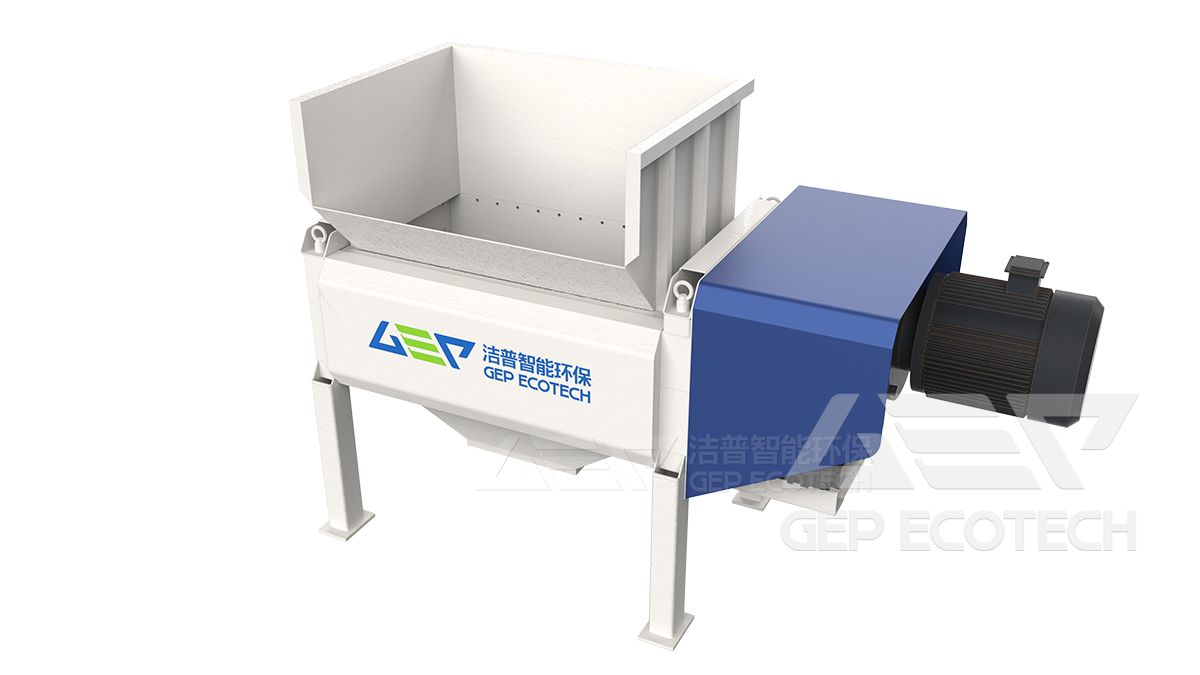

Learn MoreGEP ECOTECH Core Equipment Shredder Chapter

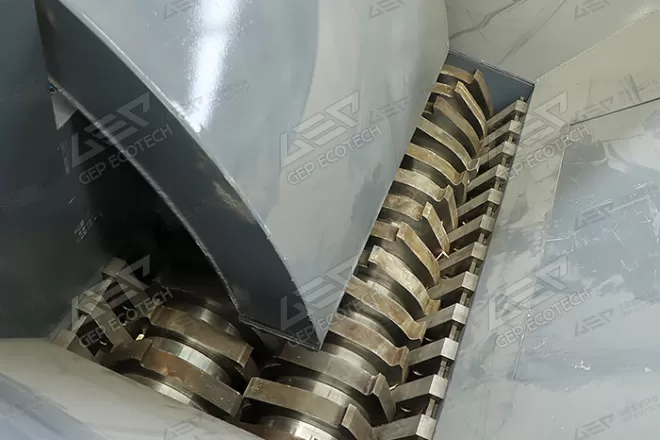

Relying on GEP ECOTECH's strong R&D and manufacturing capabilities and rich project operation experience, the GEP ECOTECH's shredder has won widespread recognition in the market.Double-shaft shredderDouble-shaft shredder is a universal solid waste shredding equipment that utilizes cutting and tearing methods to reduce material size. The main advantage of the double-shaft shredder comes from its low speed and high torque driving method, which provides large shear force for garbage disposal applications…

Learn MoreDouble Shaft Shredder for PP JUMBO BAGS

A double shaft shredder is an effective machine for shredding and reducing the size of various materials, including PP (polypropylene) jumbo bags. These bags are commonly used in industries for storing and transporting bulk materials. Shredding PP jumbo bags can significantly reduce their volume, making them easier to handle and recycle. For example, our GDI dual-shaft shredder is specially used to process PP jumbo bags. Let us take a look at its features below. Sturdy Construction: The shredder should be…

Learn MoreHow to Turn Agricultural Waste Into Treasure?

Agricultural waste refers to the useless, surplus or waste generated in the agricultural production process, including but not limited to the following types:1. Crop straw such as wheat straw, rice straw, corn straw, soybean straw, etc;2. Waste generated during the processing of agricultural products, such as husks, weeds, roots, branches, vegetable residues, rice bran, oil bran, tofu residue, etc;3. Livestock and poultry manure, decomposed carcasses, fish, shrimp, crabs, and other livestock waste;4. Waste…

Learn MoreRecycling and Utilization of Discarded Agricultural Film

Agricultural film, also known as thin film plastic, including plastic film, is mainly used to cover farmland, improving soil temperature, maintaining soil moisture, promoting seed germination and rapid seedling growth, and inhibiting weed growth. The main component of agricultural film is non degradable polyethylene, so waste agricultural film can cause certain pollution to soil and water sources, and its recovery and reuse are very necessary.The methods for recycling discarded agricultural film include:1…

Learn MoreDismantling and Recycling Methods for Scrapped Power Batteries

The dismantling and recycling of power batteries refers to the centralized recycling of scrapped power batteries, and the recycling of valuable metals such as nickel, cobalt, manganese, copper, aluminum, lithium, etc. in the batteries through process technology, followed by the recycling of these metal materials. At present, the main methods for dismantling and recycling power batteries include physical recycling, wet recycling, and pyrometallurgical recycling.Physical recycling is the process of obtaining…

Learn MorePlastic Shredding Machines for Sale in New Zealand

With the growing concern over plastic waste pollution and its impact on the environment, the demand for efficient plastic shredding solutions has surged worldwide. In response to this pressing need, GEP ECOTECH, a leading environmental technology company, offers state-of-the-art plastic shredding machines for sale in New Zealand. These cutting-edge machines are designed to handle various types of plastic waste and contribute to the reduction of plastic pollution while promoting a sustainable circular…

Learn MoreCommon Faults and Troubleshooting Methods of Double-Shaft Shredder

1、 Double-shaft shredder not working1) The power supply voltage is too high or too low → Check whether the voltage is normal.2) Broken wire, connector and terminal detachment → Repair broken wire, tighten terminal.3) The main power supply is not connected → Check if the main power supply is connected.4) Thermal relay disconnected due to overload → Reset thermal relay.5) Fuse blown → Replace fuse. 2、 Excessive tool wear1) The material contains a lot of hard objects → Install auxiliary equipment to remove…

Learn MoreMaintenance Matters For Double-Shaft Shredder

In order to ensure the normal operation of the double-shaft shredder and prevent accidents, it is necessary to regularly maintain and maintain it.1. Daily maintenance matters:A. No materials are allowed in the equipment before startup.B. No materials allowed in the equipment after shutdown.C. Is there any abnormal sound or vibration when the equipment is unloaded.D. Whether the operation buttons and touch screen of the intelligent control cabinet are normal.E. Is there any leakage of grease in the…

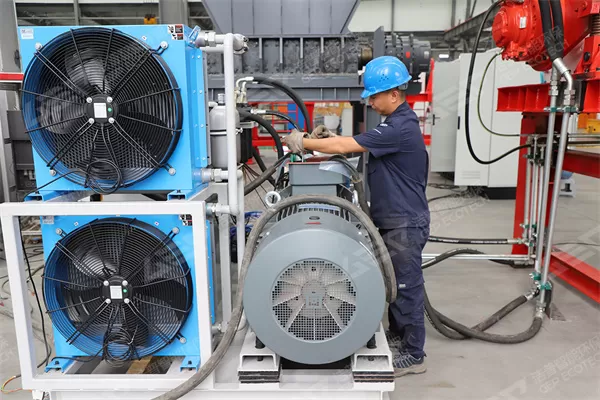

Learn MoreMotor Power of Pre Shredder Machine

Recently, many customers have asked us a question, what power motor does the pre shredder machine use? In fact, this question is not difficult to answer, but because the models of pre shredder machine s used in daily life are different, the power of the configured motors is also different. Take our pre shredder machine as an example, the motor power of the smaller model GD6 is 22-45kw, and the motor power of the larger model GD15 is 132-250kw, so our pre shredder machine uses 22-250kw motor.It is very…

Learn MoreWhich Kind of Shredder Machine Is Used for Steel Plate Less Than 7mm?

Scrap steel plates need to be processed into furnace charges by equipment before they can be used for steelmaking. Mainstream processing equipment includes shredders, shears, balers, etc. Among them, the shredder can break the blocks to remove impurities such as coatings, and facilitate storage and transportation; the shearing machine cuts the large sheets into strips; the baler compacts the scraps into blocks. General scrap steel plate needs to purchase a complete set of equipment for processing, and the…

Learn MoreWindshield Shredding Machine Choose Double Shaft Shearing Type

We can usually see the windows in the front part of vehicles such as airplanes, cars, buses, locomotives, trams and ships. These windows are usually called windshields. Modern windshields are usually made of laminated safety glass, with layers of curved glass on the inside and outside, with a layer of laminated plastic sandwiched between them for safety reasons, and then glued to the frame of the window . After being processed by a shredder, the glass of the windshield can be separated from the middle…

Learn MoreGEP ECOTECH Has a Steady Stream of Waste Disposal Equipment Orders

After a rainstorm, the sunshine weather was quickly restarted. No matter how changeable the weather is outside, the workshop of GEP ECOTECH is still busy.This is the GC series Pre-shredder shipped to Europe, which has already been loaded. This is the GD series Double-shaft shear shredder, GSS series European single-shaft shredder and GTS series trommel screen purchased by a North American customer, who will come to inspect the goods in a few days. Not long ago, the waste textile shredding sets and bulky…

Learn MoreGEP's Best Line-up of Solid Waste Disposal Lines

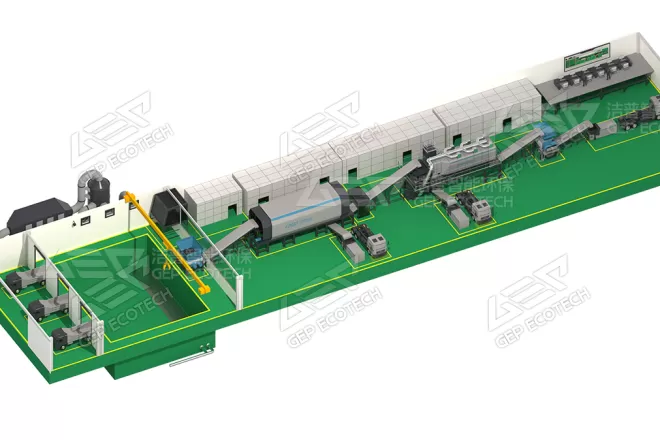

As we all know, GEP ECOTECH is well established in the fields of bulky waste shredding and capacity reduction, biomass fuel pre-treatment, general industrial waste and industrial hazardous waste comprehensive disposal, domestic waste and food waste pre-treatment, construction waste and renovation waste resource utilization, etc. We are able to customize the exclusive material disposal production line solution for each customer according to their actual needs.Among these successful applications, a…

Learn More10 Tonnes per Day Double Shaft Industrial Shredder Machine Malaysia

Yesterday, a customer inquired about the double-shaft industrial shredder equipment with a daily processing capacity of 10 tons domestic waste. When we further understood the customer's needs, we provided the customer with a detailed disposal plan and equipment quotation on the same day, and the customer was very satisfied. Why can we give professional support so quickly? I have to mention our rich experience in double-shaft industrial shredder equipment manufacturing and project installation, and continue…

Learn MoreWhen FRP Scrap Meets Shredder

FRP (Fiber Reinforced Plastics) is a composite material made of glass fibers and its products (glass cloth, tape, felt, yarn, etc.) as reinforcing material and synthetic resin as matrix material. Light and hard, non-conductive, corrosion-resistant, stable, high mechanical strength, can replace steel manufacturing machine parts and automotive, ship shells, etc., but less recycling.Based on one, the lifespan of FRP is 10-20 years and the trim waste generated during production is about 3%-5% of the output,…

Learn More20 Ton Wood Shredder Choose Double Shaft

Which equipment model should be used for a 20-ton wood shredder? A customer asked me this question today. In fact, the wood shredder with this output is considered a medium-sized equipment in our equipment. For example, the output of our GDB double shaft shredder can reach 10-60 tons/hour, and the GDB115 model is often used as a 20 tons/hour wood shredder. Then let's take a closer look at this 20-ton dual-shaft wood shredder!The role of 20 ton wood shredderThe waste wood can be processed into small pieces…

Learn MoreWind and Snow, Set Off on Time

Last weekend, the production staff of GEP ECOTECH worked overtime in spite of the snow, Shandong FRP shredding and disposal equipment and Jiangxi bulky waste shredding and disposal equipment were loaded and shipped one after another and departed on time. This is also a successful conclusion to the Year of the Ox.Apart from the classic production line equipment such as double shaft shredder, chain conveyor, belt conveyor, self-unloading iron remover, pulse dust collector and intelligent centralized control…

Learn MoreHow Much Is a Double-Shaft Shredder for Scrap Iron Sheets?

Converting scrap metal material to a specific size for further processing requires intelligent shredding solutions. The addition of a shredder to the sheet metal recycling process reduces worker risks associated with manual handling, feeding and cutting of sheet metal material, further automating the production line. The dual shaft shredder is designed with a low speed, high torque cutter to reduce sparking and easily shred thin metals such as sheet iron for further processing and handling. Reducing…

Learn MoreHow to Process Baled Metal Scraps, Overall Solution for Metal Scraps Bale Processing

Metal scraps bale is a material pressed by a special briquetting machine in the recycling metal industry in order to reduce storage and transportation costs, mainly including various types of metals, such as iron, aluminum, copper and so on. After briquetting in the recovery center, these waste metals are transported to a special metal recovery and smelting Center for subsequent recovery and disposal.In order to improve the efficiency of subsequent recovery and disposal, large equipment is generally used…

Learn MoreWhy Choose the Double Shaft Type for the Baled Aluminum Shredder?

The recycling of scrap aluminum is of great significance. For the recycling and reuse of baled aluminum, it must be pretreated by equipment such as a shredder. The scrap aluminum shredder can shred the material to a certain size, and use an electrostatic and specific gravity sorter separation. So what kind of equipment is suitable for scrap baled aluminum shredder?The double-shaft shredder has been widely used in the waste aluminum resource recycling industry. Double-shaft shredder, also known as double-…

Learn MoreHow to Improve the Crushing Efficiency of Double-Shaft Shredder Machine?

In the previous article, we introduced the reasons for the low crushing efficiency of the double-shaft shredder, so how to improve the crushing efficiency of the double-shaft shredder machine? Let us continue talking today.The double-shaft shredder equipment is preheated and idling before starting upMany people ignore this small detail, but facts have proved that the idling preheating of the double-shaft shredder equipment can greatly improve its working condition and service life.Don't make too much…

Learn More