Wood is a widely used and valuable material. Some waste wood, including industrial pallets, sleepers, medium density fibreboard (MDF), chipboard, trimmings, branches and bark, etc., can be shredded to reduce its volume and recovered and converted into a variety of valuable resources such as wood chips, biomass and fuel sticks (briquettes). Biomass produced from waste wood is one of the most popular sources of energy in some large biomass cogeneration plants.

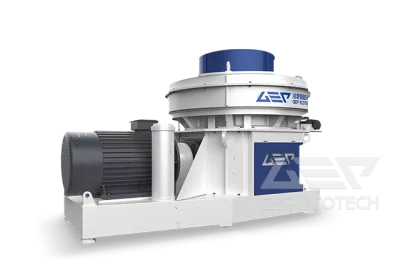

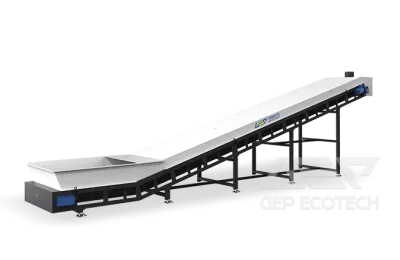

GEP Ecotech's GD series double-shaft shredder is ideal for high volume shredding of waste wood. Its high torque, low speed advantage makes it suitable for a wide range of materials and makes it easy to process waste wood to the right size with just one machine. Its stable performance makes it ideal for uninterrupted operation, making it an indispensable piece of equipment for large biomass fuel processing centres and cogeneration plants. For applications where finer sizes are required, GEP Ecotech's single-shaft range of fine shredders can work on top of the twin-shaft shredder to process material to a uniform particle size of up to 10mm.