Trust Continues! GEP ECOTECH Assists in the Establishment of an Efficient Alternative Fuel Production Line for Waste Sorting Centers

The Zhongyuan District Domestic Waste Sorting Center, as the core hub for regional waste terminal disposal, shoulders the critical responsibilities of sorting, pre-processing, and resource utilization for all domestic waste in the district. Previously, GEP ECOTECH had tailored three intelligent disposal systems for bulky waste, waste textiles, and food waste, establishing an efficient and coordinated waste terminal disposal system. It is this accumulated experience of "reliable and hassle-free"…

Learn MoreCan the Mold Size of an RDF Pellet Mill Be Customized Absolutely? Here's Why It Matters

If you're investing in Refuse-Derived Fuel (RDF) production technology, this isn't just a question—it's one of the most critical factors determining your operation's profitability and efficiency. The short answer is a definitive yes.At GEP ECOTECH, we don't just support customization. We consider it a fundamental principle of our product design and engineering philosophy. A one-size-fits-all approach is ineffective in waste management. Your feedstock is unique, your output goals are specific, and your…

Learn MoreKey Factors Affecting RDF Pelletizing Machine Performance: Material Composition, Moisture, Impurities & Equipment Selection

IntroductionRDF (Refuse-Derived Fuel) pelletizing machines play a vital role in converting waste materials into high-density, energy-efficient fuel pellets. However, the pelletizing efficiency, pellet quality, and production output depend on several critical factors, including raw material composition, moisture content, impurity levels, and proper equipment selection. Understanding these factors ensures optimal performance and maximizes ROI for waste-to-energy projects.1. Raw Material Composition & Its…

Learn MoreVersatile Raw Material Processing with RDF Pelletizing Machines

RDF (Refuse-Derived Fuel) pelletizing machines are engineered to transform a wide range of waste materials into high-density, energy-efficient fuel pellets. These machines play a crucial role in sustainable waste management and renewable energy production by processing diverse raw materials into usable RDF.Key Raw Materials Processed by RDF Pelletizing Machines1. Municipal Solid Waste (MSW)RDF pelletizing machines efficiently process non-recyclable municipal waste, including:Paper & cardboard…

Learn MoreRDF Project with an Annual Output of 55,000 Tons in the Middle East

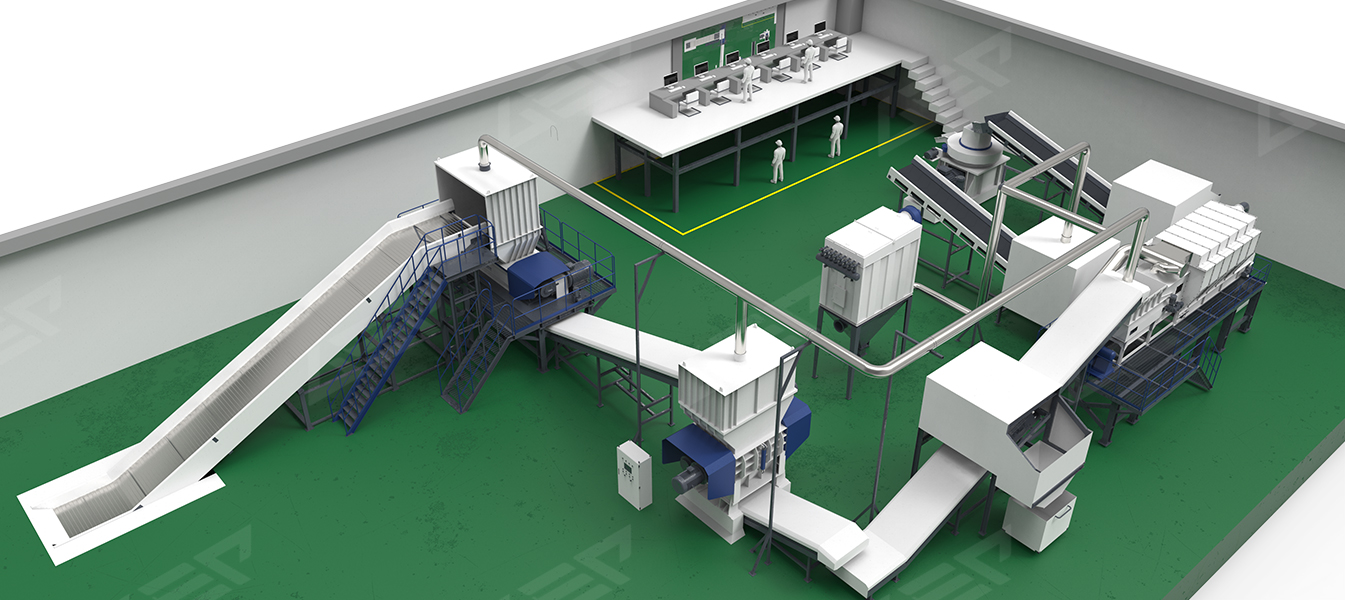

GEP ECOTECH provided a customized RDF production solution for the first waste-derived fuel (RDF) plant in a Middle Eastern country, deploying multiple RDF preparation units to build an intelligent production line with an annual capacity of 55,000 tons. The project integrates wheel loader feeding, intelligent sorting, belt conveying, precise dosing, and pelletizing, while continuously monitoring key indicators such as moisture and calorific value to ensure product quality. This solution facilitates the…

Learn MoreAnnual Production Of 100000 Tons Of Alternative Fuel, See How Waste Spinning Transforms Into a 'Green Fuel Warehouse' In The Cement Industry

Driven by carbon peaking and carbon neutrality goals, China continues to promote the clean transformation of high emission industries. With the "14th Five Year Plan" for the development of circular economy clearly proposing the "coordinated disposal of urban waste by cement kilns and smelting kilns" and the "Special Action Plan for Energy Conservation and Carbon Reduction in the Cement Industry" requiring the proportion of production lines using alternative fuel technology in cement kilns to reach 30% by…

Learn MoreChina Yangtze River Delta Annual Production of 100,000 Tons of Textile Waste to Alternative Fuel Project

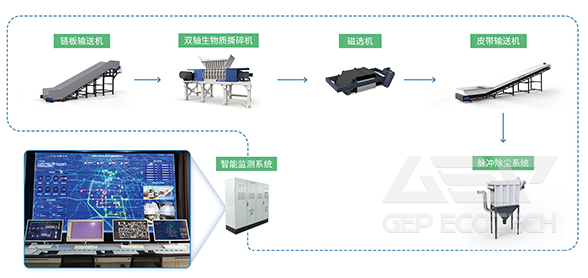

Compared to coal powder, waste spinning has the advantages of high volatile matter, low ash content, low moisture content, and considerable calorific value (average around 4,300 kcal), and has good potential as a substitute fuel. GEP ECOTECH has tailored this fuel pretreatment solution for customers, covering processes such as three-stage double shaft shredder shredding, magnetic separator for iron removal, and baling machine for compression. In this scheme, specific design adjustments are made to the…

Learn MoreAdvanced RDF Treatment Line for Industrial Waste Management in France

Project profileThe customer is a strong company that does resource disposal of industrial solid waste in China. The processing materials are mainly combustible such as plastic bags, oily paper, waste clothing, and seasonal straw. Through the fully automated shredding, sorting and RDF molding process configured by GEP ECOTECH, industrial solid waste is converted into high-density and high-calorific RDF fuel, which is then sold to local coal-fired power plants for use, reducing coal consumption, reducing…

Learn MoreIntroduction to GEP ECOTECH Cement Kiln Alternative Fuel (SRF/RDF) Preparation System

GEP ECOTECH is a national high-tech enterprise driven by technological innovation and social responsibility, a provincial-level solid waste equipment technology research center, a provincial-level specialized and refined new enterprise, and a high-quality alternative fuel preparation solution and equipment supplier for cement kilns. The company's business scope covers five major fields in the construction of the national "waste free city", including industry, agriculture, daily life, construction, and…

Learn MoreAlternative Fuels For Cement Companies, See The GEP's Solution

Jointly hosted by China Building Materials Circulation Association (CBMCA), China Cement Technology Network (CCTN) and China Cement Building Materials Centre, Beijing (BCMC), the "2023 Cement Industry Upgrading and Efficiency Enhancement and Intelligent New Technology and Equipment Exchange Conference under the Background of Dual-Carbon" was successfully held on 26th - 28th July 2023 at Zhengzhou Chantilly Bay Hotel. Industry technical experts, scientific research units, colleges and universities, cement…

Learn MoreRDF Preparation Technology, One of the Waste Furniture Recycling Methods

IntroductionWith the acceleration of urbanization, the disposal of used furniture has become an urgent problem. Traditional disposal methods mainly include landfill and incineration, which not only cause environmental pollution but also waste a lot of resources. Therefore, RDF production technology, as a new type of used furniture treatment technology, has gradually received attention and attention from people.Principles and Process of RDF TechnologyRDF technology refers to the processing of combustible…

Learn MoreHow Much Is RDF Fuel Rod per Ton?

What is the most popular concept of solid waste treatment? RDF fuel rods are definitely on the list. RDF, short for RefuseDerivedFuel, has high caloric value, stable combustion, easy transportation, easy storage, low secondary pollution and low emissions of dioxins, and is widely used in drying engineering, cement manufacturing, heating engineering and power generation.So in the context of the two-carbon target, RDF technology becomes popular, opening up more possibilities for recycling waste. Therefore,…

Learn MoreRecycling RDF from Waste for Cement Plants

Alternative fuel RDF (Refuse Derived Fuel) refers to solid secondary substances that are produced from waste and serve as a fuel in some types of production. Typically RDF is used as a supplemental or primary fuel in plants that operate smelting or reheating furnaces at high temperatures.The incineration of RDF in such kilns is much safer than using plain MSW, as cement plant heating kilns typically operate at temperatures of 1600 ° C or more. In such conditions, the overwhelming majority of harmful…

Learn MoreRefuse-Derived Fuel & Solid Recovered Fuel System

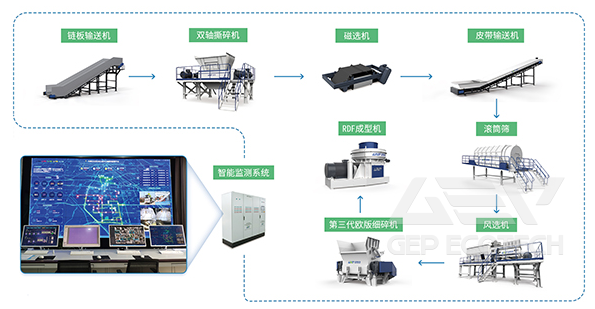

Solid waste is fed into the shredding plant using a belt or feeder to reduce the material to the required size. For most materials, a twin or four-shaft shredder can be used to process the material to the target size in one pass; for piles or bales, a pre shredder can be used to increase production and reduce the wear and tear on the core equipment. Use of an iron remover to remove ferrous materials and windrow or other equipment to remove other materials that cannot be burned. Pressing the material into…

Learn More