RDF (Refuse-Derived Fuel) pelletizing machines are engineered to transform a wide range of waste materials into high-density, energy-efficient fuel pellets. These machines play a crucial role in sustainable waste management and renewable energy production by processing diverse raw materials into usable RDF.

Key Raw Materials Processed by RDF Pelletizing Machines

1. Municipal Solid Waste (MSW)

RDF pelletizing machines efficiently process non-recyclable municipal waste, including:

- Paper & cardboard scraps

- Textiles & leather remnants

- Plastic films & packaging materials

- Organic residues (after drying)

2. Industrial & Commercial Waste

Manufacturing and commercial sectors generate large volumes of combustible waste, such as:

- Wood chips & sawdust

- Rubber & foam waste

- Non-hazardous industrial sludge

- Rejected packaging materials

3. Agricultural & Biomass Waste

Sustainable fuel production is possible by converting agricultural byproducts, including:

- Crop stalks & straw

- Rice husks & coconut shells

- Bagasse & other agro-residues

4. Rejected Materials from Recycling Facilities

Even materials unsuitable for traditional recycling can be repurposed into RDF:

- Mixed plastic waste

- Contaminated paper & textiles

- Composite material scraps

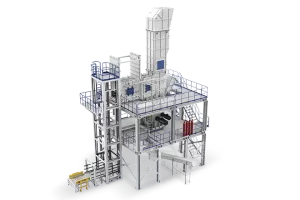

Why Choose GEP ECOTECH RDF Pelletizing Machines?

✔ High Adaptability – Handles varying moisture levels and material compositions.

✔ Efficient Densification – Produces uniform, high-calorific-value fuel pellets.

✔ Eco-Friendly Solution – Reduces landfill dependency and supports circular economy goals.

By processing these diverse waste streams, our RDF pelletizing machines help industries reduce disposal costs while generating alternative energy sources.

Contact us today to find the ideal RDF solution for your waste-to-energy needs!