Introduction

RDF (Refuse-Derived Fuel) pelletizing machines play a vital role in converting waste materials into high-density, energy-efficient fuel pellets. However, the pelletizing efficiency, pellet quality, and production output depend on several critical factors, including raw material composition, moisture content, impurity levels, and proper equipment selection. Understanding these factors ensures optimal performance and maximizes ROI for waste-to-energy projects.

1. Raw Material Composition & Its Impact on RDF Pelletizing

Different waste materials have varying binding properties, calorific values, and compaction behaviors. Key material categories include:

a) Fibrous Materials (Paper, Cardboard, Textiles)

- Advantages: Good binding properties, easy to compress.

- Challenges: Low calorific value if overly dominant; may require additives for better combustion.

b) Plastics & Films

- Advantages: High calorific value, improves pellet durability.

- Challenges: Excessive amounts can cause melting issues in the extruder; may require controlled ratios.

c) Organic & Biomass Waste (Food Waste, Wood, Agricultural Residues)

- Advantages: Renewable, carbon-neutral fuel source.

- Challenges: High moisture content may require pre-drying; inconsistent density if not properly shredded.

d) Inert Materials (Glass, Metals, Stones – Must Be Minimized)

- Negative Effects: Wear & tear on machine parts, poor pellet formation, reduced combustion efficiency.

Optimal Mix Recommendation: A balanced blend of fibrous materials (30-50%), plastics (20-30%), and biomass (20-40%) ensures stable pellet formation and high energy output.

2. Moisture Content: A Critical Factor in RDF Pelletizing

Moisture significantly affects pellet density, machine efficiency, and final product quality.

- Ideal Moisture Range: 10-20% (Varies by material type)

- Too High (>25%): Causes poor compression, clogging, and mold growth in storage.

- Too Low (<8%): Reduces natural binding, leading to brittle pellets.

Solutions:

- Pre-drying systems for high-moisture waste.

- Moisture sensors & automated feed control in advanced RDF machines.

3. Impurity Levels & Their Impact on Machine Performance

Impurities (metals, stones, ceramics) negatively affect:

- Machine Wear: Increases maintenance costs due to abrasion.

- Pellet Quality: Causes cracks, low density, and inconsistent burning.

Recommended Impurity Control Methods:

- Pre-sorting (Magnetic Separators, Air Classifiers) – Removes metals & heavy contaminants.

- Shredding & Screening – Ensures uniform particle size for better compression.

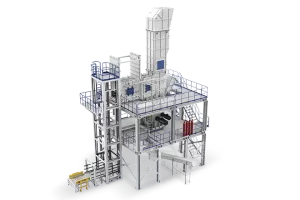

4. Equipment Selection: Matching the Machine to Your Raw Material

Choosing the right RDF pelletizing machine depends on:

a) Material Characteristics

- High-Plastic Waste → Requires heavy-duty extrusion with cooling systems.

- High-Fiber Waste → Needs strong compression rollers & binding agents.

b) Production Capacity Requirements

- Small-Scale (1-3 T/H) → Suitable for municipal waste projects.

- Large-Scale (5-10 T/H) → Ideal for industrial & commercial waste processors.

c) Advanced Features for Optimal Performance

- Adjustable Die & Roller Systems – Adapts to different material densities.

- Automated Moisture Control – Ensures consistent pellet quality.

- Wear-Resistant Components – Extends machine lifespan in abrasive conditions.

Conclusion: Maximizing RDF Pellet Quality & Output

To achieve high-quality RDF pellets with maximum production efficiency:

✔ Analyze material composition and adjust the mix for optimal binding.

✔ Control moisture levels (10-20%) to prevent clogging & ensure pellet durability.

✔ Remove impurities to reduce machine wear and improve combustion efficiency.

✔ Select the right RDF pelletizing machine based on material type and capacity needs.

Partner with GEP ECOTECH for customized RDF production solutions that enhance your waste-to-energy productivity!