Closing of 2025 · Empowering "Carbon Peaking and Carbon Neutrality" | GEP ECOTECH's Two Benchmark Projects for Alternative Fuels Successfully Landed, Writing a New Chapter in Resource Utilization

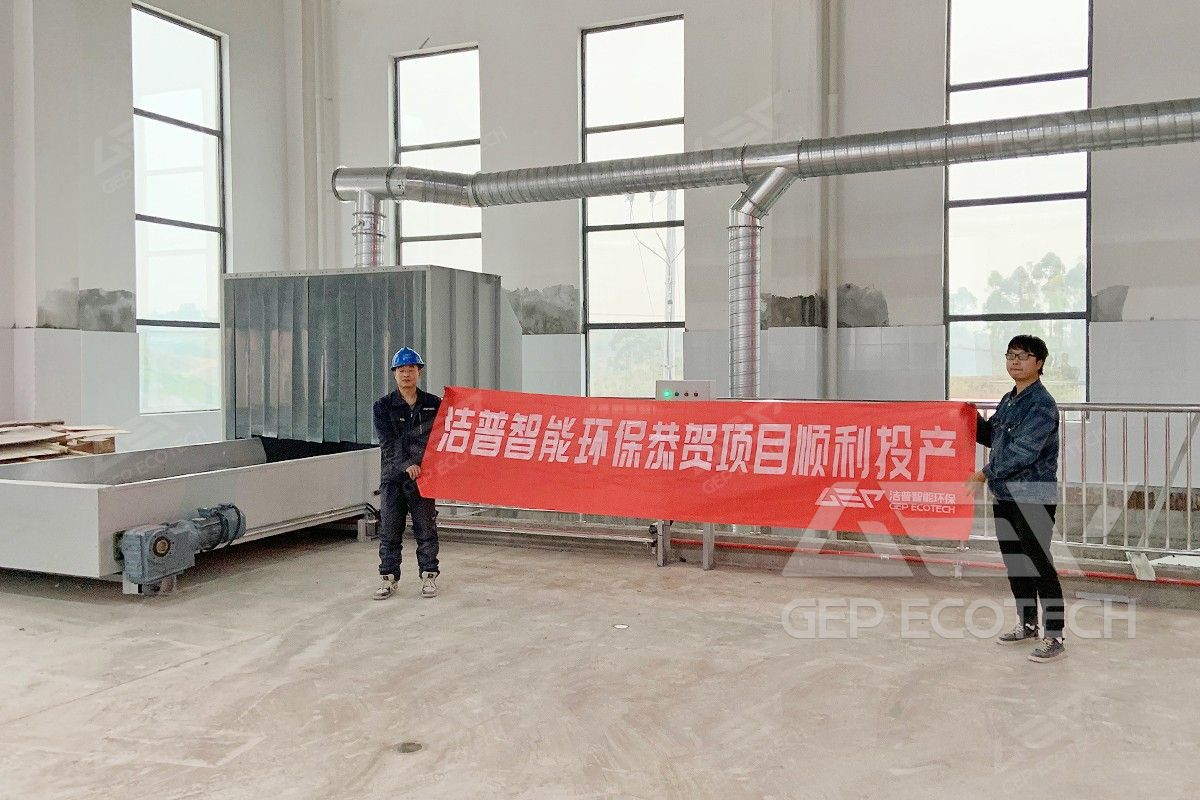

Among them, the successful delivery of the MSW to Alternative Fuel Production Project in the Middle East and the Construction Waste Combustibles to Alternative Fuel Project in Shanghai not only became a benchmark model for regional solid waste resource utilization, but also demonstrated the core value of alternative fuels in breaking the "garbage siege" and promoting energy transformation, drawing a satisfactory conclusion to the annual development.

Learn MoreConstruction Waste Combustibles to Alternative Fuel Project in Shanghai

This project successfully transformed construction waste combustibles into high-quality alternative fuel in Shanghai for an environmental technology company. The implemented waste recycling equipment is centered around a carefully selected configuration, including the vibrating feeder, ballistic screen, magnetic separator, single shaft shredder, waste baler, etc., forming a complete and efficient alternative fuel production line. The system delivers stable output of 3–5 tons per hour, providing reliable…

Learn More50TPH Dual-Output Waste-to-Fuel Project in the Middle East

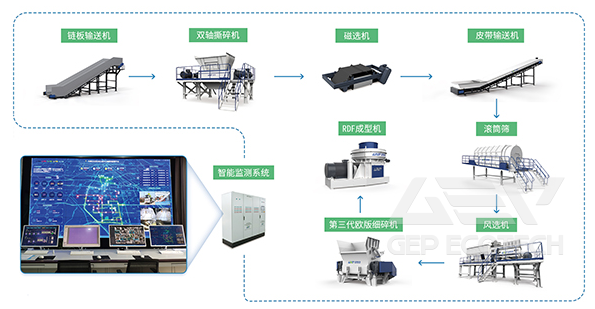

This project is a 50TPH Dual-Output Waste-to-Fuel Project commissioned by a leading MSW Management company in the Middle East. It represents a complete domestic waste recycling solution, integrating our robust "Tough-Processing" unit (customized bag opener) and "High-Precision Sorting" suite (trommel screen, magnetic separator, etc.). The MSW recycling line is designed to efficiently transform challenging, high-moisture municipal solid waste into high-quality alternative fuel. Its core innovation is a…

Learn MoreASR (Automotive Shredder Residue) to SRF Production Line in Taiwan

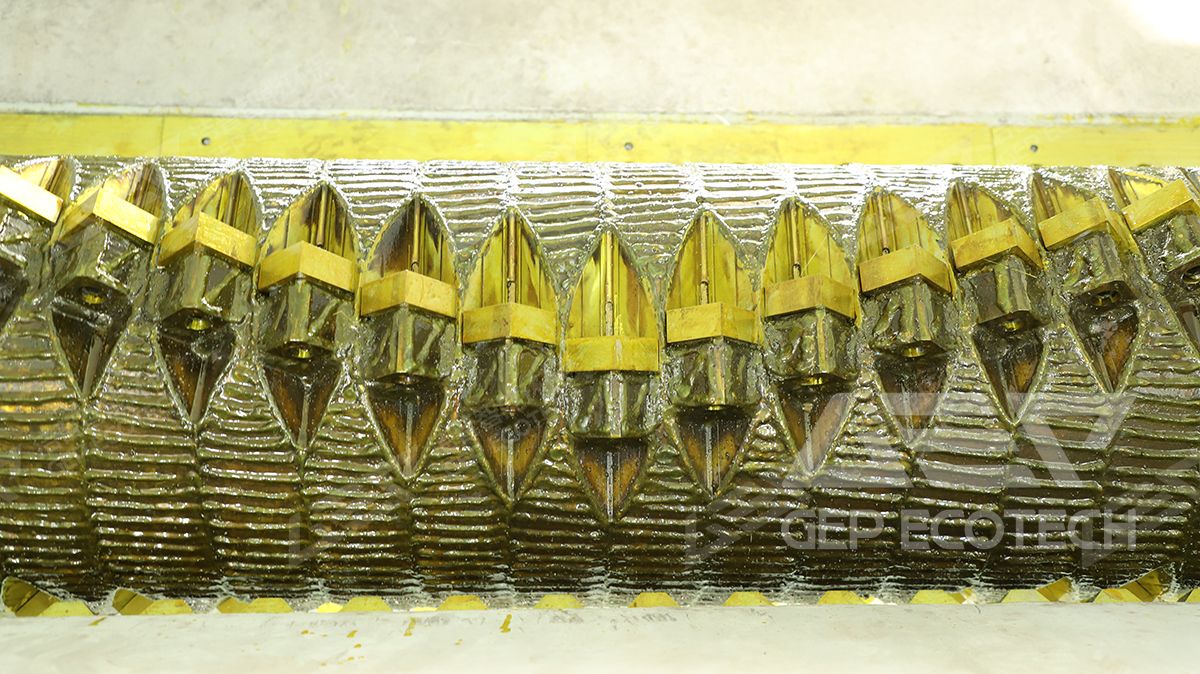

A leading auto dismantler in Southern Taiwan, processing 3,000-4,000 cars monthly, selected GEP ECOTECH's complete ASR processing plant to address their growing waste challenges. The integrated system effectively transforms automotive shredder residue into high-quality solid recovered fuel (SRF) through multi-stage shredding and advanced separation equipment. The solution achieves precise 30mm output specification (through a four-shaft shredder) critical for optimal SRF Shredding, with reliable 8t/h…

Learn MoreTrust Continues! GEP ECOTECH Assists in the Establishment of an Efficient Alternative Fuel Production Line for Waste Sorting Centers

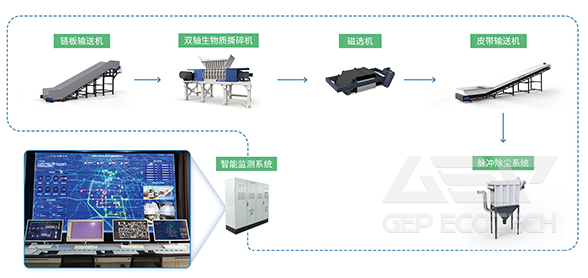

The Zhongyuan District Domestic Waste Sorting Center, as the core hub for regional waste terminal disposal, shoulders the critical responsibilities of sorting, pre-processing, and resource utilization for all domestic waste in the district. Previously, GEP ECOTECH had tailored three intelligent disposal systems for bulky waste, waste textiles, and food waste, establishing an efficient and coordinated waste terminal disposal system. It is this accumulated experience of "reliable and hassle-free"…

Learn MoreLight Materials From Decoration Waste Can Be Transformed Into Fuel in Seconds

Energy Treasure: Re evaluation of the Value of Light Materials in Decoration WasteAbout 30% of the light materials in decoration waste, such as wood, plastic, fabrics, etc., contain enormous energy value. These combustibles can be scientifically processed and converted into solid recycled fuel (SRF) and waste derived fuel (RDF), with a calorific value of 3500-6000 kcal/kg, close to the level of coal. This transformation not only reduces the land resources occupied by landfilling, but also reduces 1.5 tons…

Learn MoreChina Yangtze River Delta Annual Production of 100,000 Tons of Textile Waste to Alternative Fuel Project

Compared to coal powder, waste spinning has the advantages of high volatile matter, low ash content, low moisture content, and considerable calorific value (average around 4,300 kcal), and has good potential as a substitute fuel. GEP ECOTECH has tailored this fuel pretreatment solution for customers, covering processes such as three-stage double shaft shredder shredding, magnetic separator for iron removal, and baling machine for compression. In this scheme, specific design adjustments are made to the…

Learn MoreHow to Process Palm Fruit Fiber into RDF Alternative Fuel

Palm fruit fiber, a byproduct of palm oil production, has the potential to be transformed into Refuse-Derived Fuel (RDF) as an alternative energy source. With its renewable nature, calorific value, and abundant supply in palm-producing regions, palm fruit fiber can be processed into RDF through several steps. Collection and Drying: Collect the raw fiber from palm oil mills and reduce its high moisture content (40–60%) using rotary dryers or solar drying to below 15%.Size Reduction: Shred and grind the…

Learn MoreShredding Municipal Solid Waste into Power Plant Fuel

As global energy demands rise, power plants are exploring innovative fuel sources to improve sustainability and reduce dependency on traditional fuels. One promising alternative is utilizing shredded municipal solid waste (MSW) as a fuel for boilers. This article delves into the benefits of using shredded MSW for power generation, the shredding requirements for fuel-grade waste, and the recommended shredding machine models for this application. Why Use Shredded Municipal Solid Waste as Power Plant Fuel?…

Learn MoreExpanding the Carbon Market to Stimulate New Opportunities for Alternative Fuels

On September 7th, 2024, the Global Energy Transition Conference opened in Beijing. At the meeting, Minister of Ecology and Environment Huang Runqiu stated that the national carbon emission trading market is about to undergo significant expansion, and key emission industries such as steel, cement, and aluminum smelting will be included by the end of this year.Subsequently, on September 9th, the Ministry of Ecology and Environment officially released the "Work Plan for the National Carbon Emission Trading…

Learn MoreIndustrial Shredders in Converting Waste to Fuel

As industries strive to address environmental challenges and enhance sustainability, converting waste into fuel has emerged as a significant solution. Industrial shredders play a pivotal role in this process by preparing waste materials for transformation into valuable energy sources. This article examines the function of industrial shredders in waste-to-fuel projects and explores the types of shredders commonly used in these applications.Role of Industrial Shredders in Waste-to-Fuel ProjectsIndustrial…

Learn MoreCarbon Black Alternative Fuel for Cement Plants

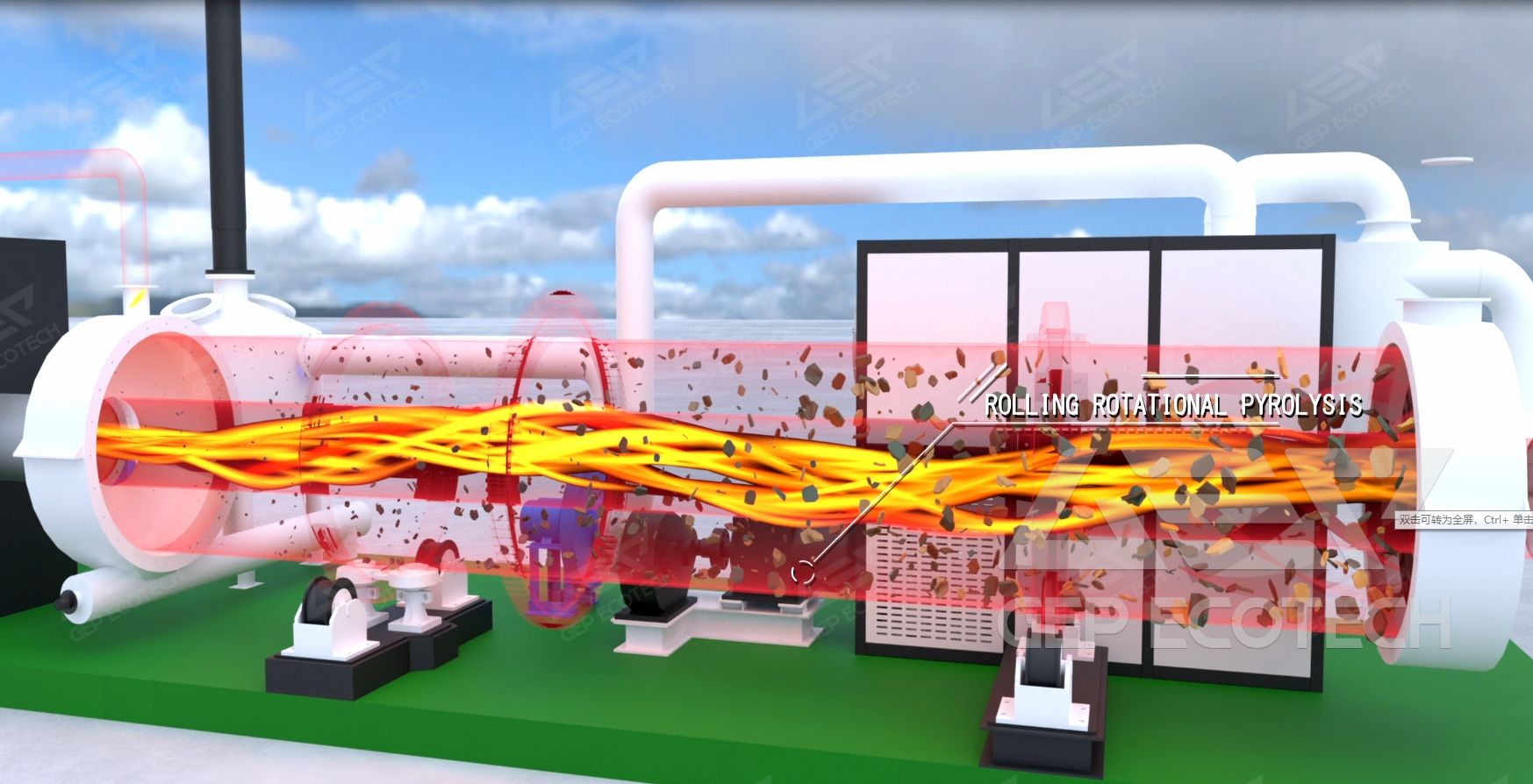

Carbon black is produced by decomposing rubber through thermal decomposition or hot pressing. The main source of raw materials is waste tires. One ton of waste tires can be pyrolyzed to obtain 0.35 tons of carbon black. In recent years, due to rising coal prices and pressure to reduce dual-carbon emissions, many cement companies have begun to use rubber cracking carbon black as an alternative fuel.Characteristics of carbon black alternative fuel for cement plants Pyrolytic carbon black has low volatile…

Learn MoreWaste Textile Alternative Fuel in Cement Industry

The main sources of textile waste are waste textiles (such as waste silk, residual materials, scraps, etc. in the textile manufacturing process) and old textiles (old clothing, bedding, curtains, carpets, etc.).The calorific value of waste textile is around 4000-7000 kcal, and the average calorific value is basically around 4300 kcal. The volatile matter is about 80-90% (pulverized coal is about 27%), the ash content is about 1-6% (pulverized coal is about 15%), and the moisture content is about 4% (…

Learn MoreBiomass Alternative Fuel in Cement Industry

Cement and its concrete products are the second most used products in human society after water. In recent years, cement companies have begun to gradually increase the proportion of alternative fuels in order to reduce production costs, increase environmental protection attributes, and reduce carbon emission intensity. Biomass fuel is an important development direction.Biomass Alternative Fuel Types and CharacteristicsAt present, through literature review and research, alternative fuels that can be used in…

Learn MoreUse Waste Fabric Screening Technology for Efficient Thermal Energy Conversion

In the industrial sector, waste textile fabrics hold potential as a valuable resource for generating heat energy through incineration. However, the presence of impurities, such as ceramic concrete blocks and metal, necessitates effective screening during the pretreatment stage to safeguard equipment and ensure efficient energy conversion.Shredding and Screening Equipment for Gep Ecotech's Alternative Fuel Production ProjectChallenges in Material PurityThe presence of ceramic concrete blocks and metal…

Learn MoreInnovative Solutions for Waste Plastic Recycling and Alternative Fuel Generation

According to data from the China Material Recycling Association, in 2022, the total production of plastic products in China was 63 million tons, of which 18.9 million tons were recycled, accounting for 30%. The recycling capacity is significantly insufficient, and a large amount of waste plastic has not been effectively utilized. Correspondingly, before the implementation of the “Ban on Waste” in 2017, China imported millions of tons of waste plastics annually for industrial production. Even in 2017, there…

Learn MoreWhy Use a Fine Shredder As Secondary Process for Processing Alternative Fuels

In recent years, twin-shaft shredders have garnered widespread recognition as primary shredders in solid waste crushing applications. However, single-shaft shredders hold a distinct advantage over their double-shaft counterparts in their ability to process materials into finer sizes. Consequently, single-shaft shredders are frequently deployed as fine shredders for secondary crushing following double-shaft shredders. This is particularly evident in the realm of alternative fuel processing, where single-…

Learn MoreShred Clothing As an Alternative Fuel for the Cement Plant

As the world continues to grapple with the challenges of waste management and environmental sustainability, innovative solutions are emerging to repurpose discarded materials for the benefit of various industries. One such groundbreaking approach involves shredding clothing to serve as an alternative fuel source for cement plants. The Challenge of Clothing WasteThe fashion industry is notorious for producing a significant amount of textile waste, with discarded clothing contributing to overflowing…

Learn MoreCarbon Emission Quotas to Be Released, Time to Learn More About Alternative Fuel Processing Equipment

According to the Chinese government website, the Provisional Regulations on the Management of Carbon Emission Trading will be implemented from May 1, 2024. The ecological and environmental management department of the State Council will work with relevant departments to formulate the total amount and distribution plan of annual carbon emission quotas. The provincial ecological and environmental management department, in conjunction with relevant departments at the same level, will distribute carbon…

Learn MoreConvenient, Safe, and Stable, This Alternative Fuel RDF/SRF Production Tool Is Worth Having!

With the promotion of the "dual carbon" goal and the upcoming release of CCER, the demand for energy consuming large households such as power plants, cement plants, and paper mills to replace coal with alternative fuels has become increasingly strong, making this alternative fuel derived from household waste, industrial waste, construction waste, and agricultural and forestry waste a hot commodity in the market. Nowadays, there are signs of a shortage of alternative fuels, and relevant departments have…

Learn MoreUnveiling the GEP ECOTECH Shredder's Popularity in Cement Kiln Alternative Fuel Pretreatment

In the cement industry, alternative fuels refer to those that can replace traditional fossil fuels, including biomass alternative fuels and non biomass alternative fuels. These alternative fuels are usually prepared from combustible waste, such as waste tires, household waste, industrial waste, straw, waste oil, tar, garbage biogas, etc.At present, most cement enterprises use cement kiln collaborative disposal production lines to produce alternative fuels with low pre-treatment and disposal quality,…

Learn MoreHighly Sought-After Bulky Waste Alternative Fuel System Now Available

The ignition ceremony for the No.1 boiler of a sludge and industrial solid waste resource utilization project provided by GEP ECOTECH for industrial solid waste disposal equipment has been successfully held recently; The insulation paper shredding production line, with the GSS series European single rotor fine shredder as the core equipment of GEP ECOTECH, has also been orderly put into production in a certain city in northwest China; GEP ECOTECH's European construction waste disposal project and North…

Learn MoreShredding Shoes to Make Fuel Blocks

Shredding shoes to create fuel blocks involves transforming worn-out or discarded shoes into a form that can be used as a fuel source. Here's a basic overview of the process:Shoe Collection and PreparationCollection: Gather worn-out or unwanted shoes that are no longer suitable for wearing.Preparation: Remove any metal parts or non-combustible materials from the shoes. This may involve cutting the shoes into smaller pieces or manually removing elements like metal eyelets or plastic components.Shredding Proc…

Learn MoreIntroduction to GEP ECOTECH Cement Kiln Alternative Fuel (SRF/RDF) Preparation System

GEP ECOTECH is a national high-tech enterprise driven by technological innovation and social responsibility, a provincial-level solid waste equipment technology research center, a provincial-level specialized and refined new enterprise, and a high-quality alternative fuel preparation solution and equipment supplier for cement kilns. The company's business scope covers five major fields in the construction of the national "waste free city", including industry, agriculture, daily life, construction, and…

Learn MoreAlternative Fuel Production From Light Materials in Renovation Waste

Renovation waste generated from construction, remodeling, and demolition activities often contains a significant portion of light materials such as wood, paper, and foam. These materials can be challenging to manage due to their volume and disposal costs. However, innovative approaches are emerging to harness their energy potential by converting them into alternative fuels. This article explores the process of producing alternative fuel from light materials in renovation waste, highlighting its benefits…

Learn MoreWhat Alternative Fuels Do Cement Plants Need?

In the context of the national double-carbon policy, all walks of life are actively seeking ways to reduce carbon. The cement industry, as a major carbon producer, undoubtedly has to take the lead. The carbon emission reduction of the cement industry plays a crucial role in the carbon emission reduction of the entire industry. All the major cement companies have been exploring good measures to reduce carbon. We all know that in the production process of cement, the process of fuel combustion is the highest…

Learn MoreThe Technology of Mixing Sludge and Agricultural Straw to Prepare Alternative Fuels

The combustion performance of sludge alone is poor. When waste straw is added to combustion together, the comprehensive combustion characteristic index increases and the combustion performance is improved. It proves that the mixed combustion of sludge and biomass waste is a good way for sludge resource utilization. In order to solve the problems of environmental pollution and energy shortage in today's society, the technology of mixing sludge and agricultural straw to prepare alternative fuels came into…

Learn MoreAlternative Fuels For Cement Companies, See The GEP's Solution

Jointly hosted by China Building Materials Circulation Association (CBMCA), China Cement Technology Network (CCTN) and China Cement Building Materials Centre, Beijing (BCMC), the "2023 Cement Industry Upgrading and Efficiency Enhancement and Intelligent New Technology and Equipment Exchange Conference under the Background of Dual-Carbon" was successfully held on 26th - 28th July 2023 at Zhengzhou Chantilly Bay Hotel. Industry technical experts, scientific research units, colleges and universities, cement…

Learn MoreA Indonesia Plant for Alternative Fuel Production

With the rapid development of Indonesia's industrial economy, a large amount of industrial solid waste is generated. How to treat these general industrial solid wastes in a harmless and resourceful manner has become an urgent need for most waste-producing enterprises.In order to help Indonesia's industrial waste recycling, reduction, and harmless development, GEP ECOTECH has reached a cooperation with local environmental protection companies to propose targeted alternative fuel plant for general industrial…

Learn MoreSRF Alternative Fuel Production Process

SRF Meaning: SRF is the abbreviation of Solid Recover Fuel (Solid Recover Fuel),SRF is usually refined RDF,SRF is not garbage, but clean, homogeneous, high quality, high calorific value fuel, can be used in power plants or cement plants to replace traditional fossil fuels, such as coal. And SRF is a very environmentally friendly fuel, its carbon dioxide emissions are only a quarter of coal, NOX emissions are also significantly lower.Composition analysis: SRF is usually composed of paper waste, waste wood,…

Learn MoreTyre Shredding to Be Used as Alternative Fuel in Cement Manufacturing

In recent years, the cement industry is exploring alternative fuel sources to reduce greenhouse gas emissions, improve energy efficiency, and enhance the sustainability of their operations. One such alternative fuel source is tyre-derived fuel (TDF), which is produced by shredding used tyres and using them as fuel in the cement manufacturing process.The tyre shredding process is the first step to produce TDF. A specialized machine is used to shred the used tyres into small pieces. The tire pieces should be…

Learn MoreAlternative Fuels Preprocessing Shredders

In recent years, the development and use of alternative fuels have become increasingly important due to concerns over the environmental impact of fossil fuels and the finite nature of these resources. Alternative fuels offer a sustainable and renewable solution to energy generation, and preprocessing shredders have a crucial role to play in the production of these fuels.The role of alternative fuels preprocessing shredders Alternative fuel preprocessing shredders play an important role in the production of…

Learn MoreWhat Are the Alternative Fuels for Cement Kilns?

Alternative fuels have become increasingly popular in the cement industry as a way to reduce costs and environmental impact. One way that cement kilns are using alternative fuels is by replacing traditional fossil fuels with alternative fuels.Alternative fuels that are commonly used in cement kilns include:Tires: Scrap tires can be used as an alternative fuel in cement kilns. The tires are shredded and then burned as fuel, which provides a high-temperature, high-energy burn that is ideal for the…

Learn More