In recent years, the cement industry is exploring alternative fuel sources to reduce greenhouse gas emissions, improve energy efficiency, and enhance the sustainability of their operations. One such alternative fuel source is tyre-derived fuel (TDF), which is produced by shredding used tyres and using them as fuel in the cement manufacturing process.

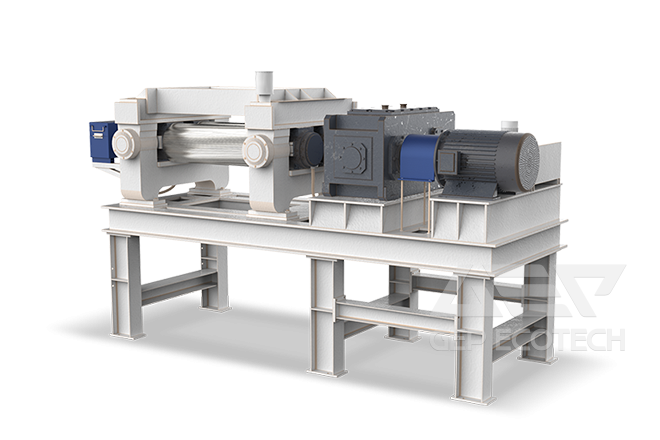

The tyre shredding process is the first step to produce TDF. A specialized tyre shredder machine is used to shred the used tyres into small pieces. The tire pieces should be of uniform size and shape to ensure proper combustion, and they should be free from any contaminants, such as dirt or rocks. During the shredding process, no hazardous chemicals or materials are produced.

Tire Shredder with an Annular Drum Screen

Why GDT tire shredders are excellent machines for producing Tire Derived Fuel (TDF)?

The high torque, high shear GDT tire shredder is ideal for processing scrap tires and producing TDF suitable for cement kilns. These four properties make it a perfect choice for this task:

- Advanced processing technology and raw materials:Both the main shaft and the tool material are made of high-strength alloy steel, which has undergone multiple heat treatments and high-precision processing, with good mechanical strength, strong fatigue resistance and impact resistance.

- Optimum Granularity: You can easily adjust the particle size of the tire shred to the required size within a 50–500 mm range. The particle size produced can be adjusted by changing the annular drum screen and adjusting the number of counter-knives, this can be done in a few minutes.

- Intelligent shredding process: Equipped with an intelligent monitoring system, it can realize remote monitoring on the computer terminal and mobile terminal, check the operation status of key parts such as equipment hydraulic pressure, bearings, motors, and reducers at any time, and take multiple measures to ensure the safe operation of the equipment.

- Less maintenance cost: The raw material of the tool is made of imported alloy steel, each fixed knife can be disassembled separately, the integral knife box is adopted, multiple combined seals are adopted, which effectively reduces maintenance costs.

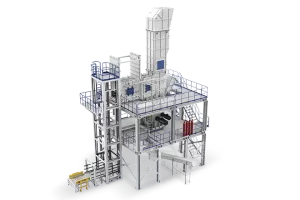

Tire-derived fuel (TDF) in Cement Manufacturing

Tire-derived fuel (TDF) is becoming an increasingly popular alternative to traditional fossil fuels in the cement manufacturing industry. Using TDF in cement manufacturing has numerous advantages over fossil fuels, including environmental, economic, and energy efficiency benefits.

- One significant advantage of using TDF in cement manufacturing is its environmental benefits. Cement manufacturing is a resource-intensive process, and the use of TDF can help reduce carbon emissions and reduce the environmental pollution generated by the traditional fossil fuels.

- TDF has a high calorific value and produces more energy than fossil fuels. This makes it an attractive option for cement manufacturers as it can help to reduce fuel costs. Additionally, TDF's consistency can benefit cement kilns, making it possible to optimize combustion and reduce the risk of hazardous emissions. The low sulphur content of TDF also reduces the potential for acid rain and other related environmental problems.

- Another significant advantage of using TDF in cement manufacturing is economic. The high calorific value of TDF means that cement manufacturers can typically achieve substantial savings on their energy bills over the long term.

- TDF can also reduce waste management costs associated with the disposal of used tires. Tire manufacturers and waste management companies that use TDF benefit from the reduced disposal costs that come with the recycling of end-of-life tires.

- The lower emissions of harmful gases resulting from the use of TDF in cement manufacturing also contribute to achieving better environmental quality, reducing pollution, and promoting better health outcomes for communities near cement plants.

In conclusion, tyre shredding to be used as alternative fuel in cement manufacturing is an attractive alternative for cement manufacturers looking to reduce operational costs, comply with environmental regulations and support sustainable development goals. However, it is important to note that the use of TDF must comply with local regulations and standards. Cement manufacturers should adhere to established guidelines and take safety precautions to ensure the proper handling and storage of TDF.