The so-called scrap tires refer to tires that have been replaced or eliminated and have lost their value as tires, as well as the end-of-life tires generated by factories. Scrap tires have a high recycling value, the output of fuel oil, carbon black, steel wire, rubber powder and other renewable resources, can create considerable economic benefits.

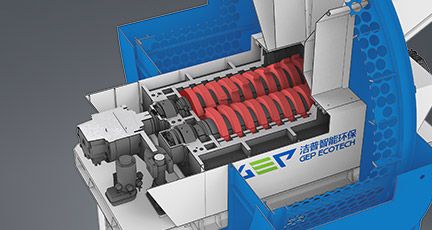

The GDT series shredder is a twin-shaft shearing type shredder developed by GEP Ecotech specifically for a wide range of waste tires. The shearing and tearing action of the shredder enables the tires to be shredded to the size required for subsequent recycling processes such as oil cracking, cement kiln incineration, tire grinding and so on, thus unlocking the potential value of waste tires and turning them into real "black gold".

GDT series double-shaft shredder has high shredding efficiency, high output, low energy consumption, and can easily cope with car tires & truck tires, diagonal tires & radial tires, pneumatic tires & solid tires, small car tires ≤ 800mm & large car tires ≥ 900mm, etc. We can also configure supporting equipment such as hydraulic tire wire pulling machine, steel wire separator, rubber breaker, screening machine, granulator, fibre separator, etc. to improve the recycling efficiency.

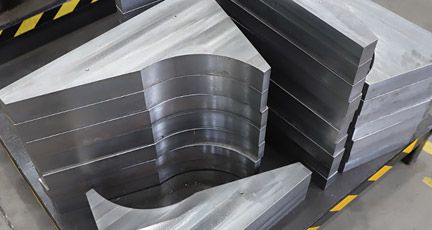

The tire shredder is designed with the structure of shredder and ring roller screen in one. When the tire enters the shredding chamber, it is sheared and torn by the relative rotating cutters, and then falls onto the rotating ring roller screen. The material that passes through the screen holes falls off directly, while the material that does not pass through the screen holes is brought back to the shredding chamber and is repeatedly sheared by the cutters until it passes through the screen holes.