The best shredder for SRF (Solid Recovered Fuel) is a topic of debate and may vary depending on the specific needs of the facility. However, in general, there are some factors that should be considered when choosing the best shredder for SRF.

Firstly, it is important to consider the throughput capacity of the shredder. Solid Recovered Fuel production plants often require shredders that can handle high volumes of waste. The shredder should be able to process large quantities of the material efficiently.

Secondly, the shredder should be designed to handle a wide variety of waste materials. SRF often contains a variety of materials, including plastics, textiles, rubber, and wood. Therefore, the shredder should be designed to handle a wide range of materials, ensuring that it can help produce consistently sized particles.

Thirdly, the maintenance and servicing requirements of the shredder should be considered. The shredder should be easy to maintain, and the replacement of cutting blades should be simple and straightforward. This ensures that the shredder is running at peak performance and minimizing downtime.

Some of the best shredders for SRF include the following:

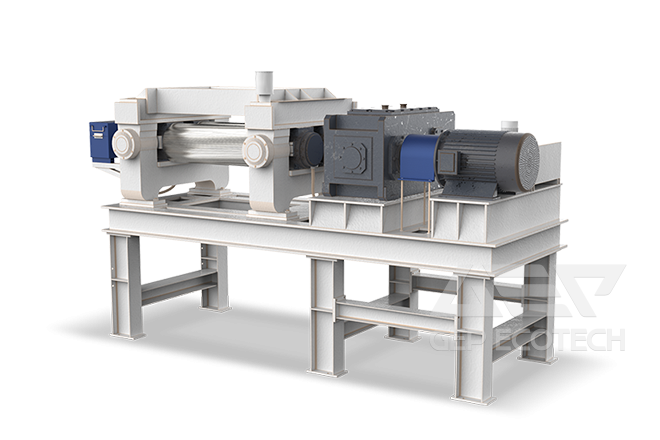

1.GD double-shaft shredder - GD double-shaft shredder is an effective type of shredder for Solid Recovered Fuel (SRF) due to its high throughput capacity and ability to handle a wide variety of materials. It is designed to handle different types of waste materials such as plastics, textiles, wood, rubber, and other materials. Waste materials are fed into the shredder through a feeder and the shredder uses two counter-rotating shafts fitted with knives or blades to cut, tear, and shred the materials into smaller pieces.

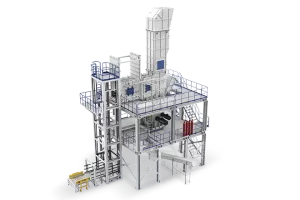

GD Double-shaft Shredder in Industrial Waste SRF Production Line

2.GSE-3 series European version single shaft shredder - It is a powerful and reliable shredder designed for difficult materials,moreover, its discharge size is very fine and can be customized, and it is often used as the secondary fine shredding equipment for SRF production.

GSE-3 Series Single Shaft Shredder in MSW Recycling Line

In conclusion, choosing the best shredder for SRF depends on various factors such as, throughput capacity, versatility, maintenance & servicing requirements, budget, and final particle size required. Therefore, careful consideration of these factors can help determine the most suitable shredder for SRF production.