With the strengthening of social awareness of environmental protection, renewable resources will obtain greater economic benefits and government policy support in the future, especially for rubber products with high resource value and difficult processing.

Waste tires, once black pollution. Nowadays, with the help of pyrolysis technology of waste tires, the comprehensive utilization of waste tires with low pollution and high efficiency has been realized. It is processed into recycled rubber, rubber powder, carbon black and other industrial raw materials, black pollution gradually turned into "black gold".

Recycling and disposal system of waste tires to promote recycling economy of waste tires

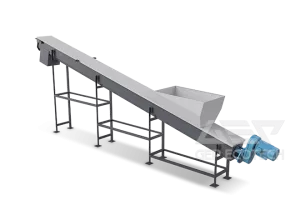

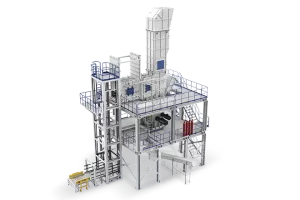

GEP waste tire recycling and disposal system uses normal temperature physical method to shred, separate steel wire, crush, fiber separation and other disposal of waste tires, making waste tires become the "black gold" of renewable resources. The production line runs at normal temperature without any chemical additives and will not cause secondary pollution to the environment.

The overall structure of GEP waste tire recycling system is compact, with low noise, high output, low energy consumption, simple operation, uniform discharge and other advantages, in line with the requirements of environmental protection. The system uses GI intelligent monitoring system to master the equipment information, real-time exception elimination, complete production information report generation and equipment predictive maintenance. Effective use of the integrated monitoring system can prevent equipment failure, save maintenance costs, and improve the stability of production capacity and production safety.

Advantages of GEP waste tire recycling and disposal system

1.Intelligent centralized monitoring to ensure safe and stable operation of equipment

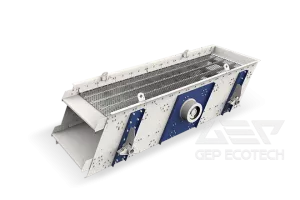

2.The cutter is solid and wear-resistant. It has strong crushing ability and improves production efficiency

3.Shearing type shredding, reduce noise and dust, good crushing effect

4.Reasonable structure design of the whole machine, convenient for equipment maintenance and overhaul

5.The discharge size can be customized to meet the personalized needs of customers

After crushing and steel wire separation, the tire will become rubber particles with the size of knuckle, and then sent to the cracking furnace to be cracked into cracking oil, carbon black and combustible gas. The whole pyrolysis process is carried out in a closed environment to minimize the leakage of pollutants. The non-condensable combustible gas generated in the treatment process will be reused for heat energy utilization in the cracking process after recovery. The cracking oil, carbon black and steel wire separated from the tire will be directly sold or further processed as renewable products to enhance the added value.

GEP ECOTECH is a comprehensive enterprise of renewable resources equipment manufacturer. It is located in Zhengzhou City, Henan Province, with strong technical force and strong mechanical processing ability. The enterprise has rich production experience, experienced years of hard work, has developed into a set of equipment research and development, manufacturing, sales and service in one of the high-tech enterprises.