Municipal solid waste (MSW) conversion technologies especially composting, landfill, and thermal treatment (combustion, pyrolysis, or gasification) have been substantially studied to improve MSW energy utilization and partially solve the environmental issues. At present, thermal treatment technologies are gradually replacing direct landfill and composting, as thermal treatment has many advantages over other processes, such as substantial reduction of waste’s weight and volume, breaking down organic wastes, and destroying bacteria and viruses during incineration.

Two types of size reduction units are in common use for the pre-shredding of MSW: traditional high speed hammer mills and the new generation low-rpm, high-torque shear shredders. Each type of the machine has unique properties for specific applications

The hammer mill crusher, relying heavily on impact forces to smash the refuse into small particles, is very effective with brittle and hard materials. Hammer mills are generally more effective in processing brittle materials, while have problems with soft and stringy materials. The impact force of the hammers is damped by ductile material and energy is absorbed and wasted in softening mechanisms, resulting in lowering the intensity of the impact force.

The shear shredder, using two opposing counter rotating blades to cut or shear materials, mainly focuses on the ductile and soft materials. The high torque generates a more even particle distribution compared to hammer mill, because shear forces are the major breakage mechanism and are less sensitive to material properties.

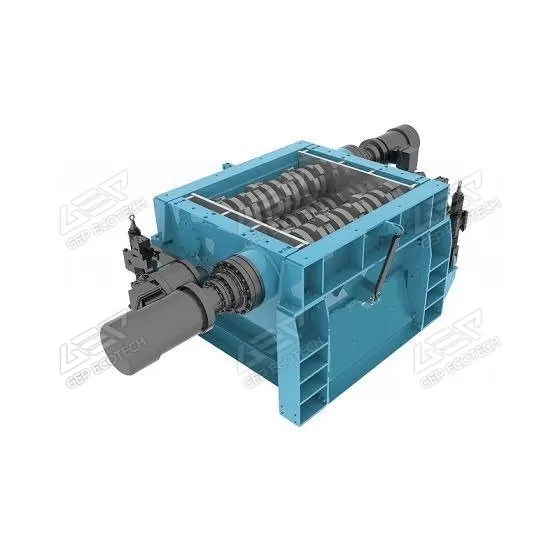

Double-shaft Shredder: New Technology for MSW Disposal

GD series double-shaft shredder have two rotating shafts, which allows them to process very hard and coarse materials. Thanks to the high strength of the knives and the hexagonal shaft system, they are able to shred hard and tough materials such as fiberglass. All shredders are supplied with automatic load control and reverse rotation (reverse) shaft speed control. When the load on the gearboxes is exceeded, the system automatically turns on the reverse and evenly distributes the raw material over the shredding chamber.