The rise of biomass energy is one of the effective ways to solve rural energy in China. Biomass energy replaces coal-fired energy, reducing greenhouse effect is the most practical and the most easily promoted renewable energy, and has great potential for development and utilization. The development and utilization of fuel compression molding such as straw is also a technological innovation in rural energy development.

Straw is the surplus by-product of harvesting the seeds after the crop matures, including stems, leaves, branches, tips, culms, shells and cores of crops such as grain, oil, cotton, hemp, sugar, tobacco, vegetables, fruits and herbs. Residues such as vines, alfalfa, ear and residue also include farmland green feed, but do not include wheat bran, cakes and other by-products and the roots of crops. Biomass straw is widely distributed and low in density. It is used in agriculture and used in agriculture to achieve the green concept of circular development. It has achieved sustainable development of the rural economy and can also achieve clean energy utilization.

Crop straw

Straw fuel utilization, including direct combustion and new energy utilization. As an important biomass energy, straw contains 40% carbon, and its energy density is 14.0~17.6MJ/kg. That is to say, 2 t straw heat energy value can replace 1 t standard coal, and the straw energy utilization can be promoted. Effectively reducing primary energy consumption, providing high-quality clean energy to rural areas, contributing to national environmental construction and CO2 emission reduction, and bringing a series of ecological, social and economic benefits.

At present, the new energy utilization of straw resources in China is mainly concentrated on the utilization of “four chemicals and one electricity”, which are solidification, carbonization, gasification, liquefaction and power generation. Biomass fuel is a renewable energy source that can replace coal as a fuel. Straw fuel belongs to environmentally-friendly renewable energy. Compared with coal, it has no pollution, zero emissions, and environmental protection is its outstanding feature. The straw energy utilization industrial chain project will be chopped and dried by straw molding equipment to produce biomass fuel. This biofuel maintains the advantages of easy ignition of straw and high calorific value.

Biomass fuel production line is one of the important equipments for straw recycling and production of environmentally friendly fuels. It is also one of the better ways for agricultural resources and forestry resources to be used efficiently and potential value to be tapped. A pile of straw is added to wastes such as sawdust and waste trees. After being crushed, packaged and compressed, it becomes a green and environmentally friendly biomass fuel. GEP ECOTECH intelligent biomass disposal production line realizes straw storage, crushing and processing, eliminating fire hazards, reducing air pollution, effectively improving straw utilization rate, and beautifying and purifying the village environment.

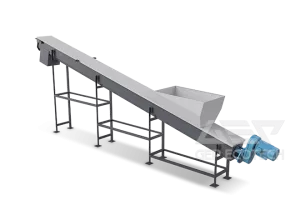

GEP ECOTECH Biomass Disposal Production Line combines conveying and crushing, and is mainly composed of chain conveyor, GE series European fine crusher and baler. According to the frequency set by the intelligent control system, the biomass straw is put into the GE series European version of the fine crusher for crushing treatment. The GE series European version of the fine crusher is a new upgraded version of the fine crusher with a single-axis "double motor + double reducer" drive design, providing large shear force to ensure high crushing output. It is often used for the fine crushing of solid waste. It can be processed into smaller particle size at one time, and is widely used in the fields of resource regeneration, RDF (domestic waste derivative fuel) production, plastic processing, and garbage disposal. It has the characteristics of small discharge particle size, screen changeable, wide material applicability and high efficiency.

The crushed straw pieces are compressed and packed into blocks.

Biomass power generation projects are biomass energy development and resource recycling. With the implementation of coal ban and non-combustion, the biomass energy industry has received strong support from the state, and some local governments have also introduced some related subsidy policies. Vigorously develop straw energy, raw material, feed, and base materials utilization, continuously optimize the technical level of straw mechanization and return to the field, and cultivate leading enterprises for comprehensive utilization of straw, effectively promoting the improvement of ecological environment, farmers' income and sustainable development of agriculture.