A washing and shredding plant for general plastics is a crucial component in the recycling industry, particularly for the effective processing of plastic waste. This type of plant combines washing and shredding processes to prepare plastic materials for recycling, contributing to the reduction of plastic pollution and the promotion of a circular economy. Let's explore the key components and processes involved in a washing and shredding plant for general plastics.

General Plastics Washing and Shredding Plant in Europe

Washing system

The washing process involves cleaning the plastic waste to remove contaminants such as dirt, labels, and residues. The washing system typically includes the following steps:

- Size Reduction: Large plastic items are often broken down into smaller pieces to facilitate washing and shredding.

- Pre-Washing: The plastic materials undergo a pre-washing phase to remove initial contaminants.

- Main Washing: Plastics are thoroughly washed using water and detergents to achieve a higher level of cleanliness.

- Rinsing: The washed plastics are then rinsed to remove detergent residues.

Shredding system

After washing, the cleaned plastic materials are fed into a shredder. The shredding process involves reducing the size of plastic pieces into smaller particles or flakes.

1.Shredding serves several purposes:

- Volume Reduction: Shredding significantly reduces the volume of plastic waste, making it easier to handle and transport.

- Facilitating Sorting: Shredded plastic is often easier to sort based on material type and color.

- Preparing for Further Processing: Shredded plastic is ready for subsequent processing steps, such as melting and extrusion.

2.Commonly used plastic shredding machine

1)Single Shaft Shredders: Single shaft shredders feature a single rotor with blades that rotate against a stationary bed knife.

- Applications: They are versatile and can handle a wide range of plastic materials, including films, bottles, and other bulky items.

- Advantages: Single shaft shredders are known for their robust design and small discharge size.

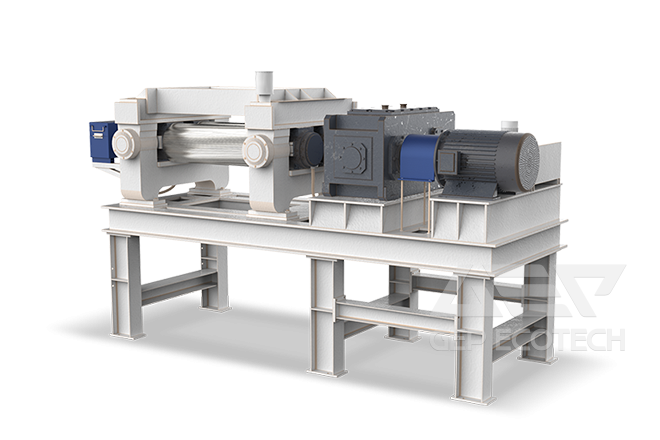

2)Dual Shaft Shredders: Dual shaft shredders have two shafts with interlocking blades that rotate in opposite directions, providing more cutting power.

- Applications: Suitable for tougher materials and large plastic items like plastic drums, pipes, and automotive parts.

- Advantages: Dual shaft shredders offer higher torque and are effective in reducing the size of bulky plastic waste.

3)Mobile Shredding Machine: Mobile shredding machines are often mounted on trucks or trailers for on-site shredding of plastic waste.

- Applications: Useful for shredding plastic waste at various locations, such as recycling events or collection points.

- Advantages: Provide flexibility and mobility for shredding operations in different locations.

In conclusion, a washing and shredding plant for general plastics is a comprehensive facility designed to process plastic waste efficiently and prepare it for recycling. This integrated approach addresses various challenges associated with plastic recycling, from cleaning and size reduction to sorting and further processing, contributing to the sustainable management of plastic waste.