Kitchen waste mainly comes from hotels, restaurants, corporate canteens and other units, and its composition is very complex, often mixed with a large amount of plastic bags, bottle caps, chopsticks, as well as broken wine bottles and tableware and other debris. GEP has designed a harmless treatment process for it: kitchen waste collection and transportation → unloading → sorting → crushing → beating → steaming → three-phase separation → water, oil, and residue.

Equipment used:

- Kitchen waste collection and transportation vehicles: There are two control methods for loading and unloading, automatic and manual, and the number of units is used according to the actual distance.

- Unloading bin: Kitchen waste is filtered through a filter tank with a 10mm mesh and enters the storage tank. The residue is pushed by an automatic push plate and transported to the automatic sorting machine by an axial spiral conveyor. It is possible to achieve the same day cleaning of ingredients, avoiding long-term accumulation and increased odor.

- Automatic sorting machine: The residue conveyed by the sorting and collection system is mainly sorted out from impurities such as wine bottle caps, plastic bags, chopsticks, etc. It is a closed type sorting machine that is safe and pollution-free. Sort out unusable debris and dispose of it as household waste; The available bones and other materials enter the crusher for crushing.

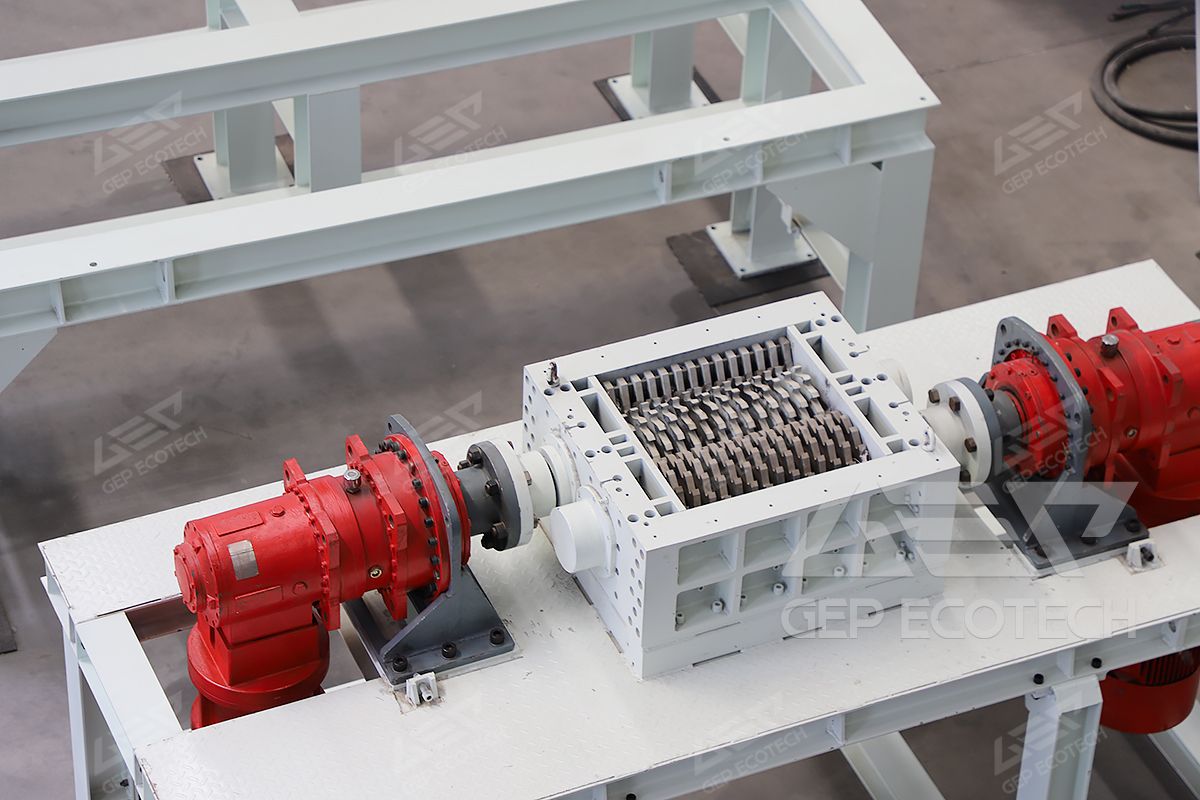

- Crusher: A double-shaft crusher specifically designed for kitchen waste is used, and the crushed material is directly transported to the pulping machine by a non axis screw. This machine has high production efficiency and good crushing effect; Fully sealed crushing, safe and pollution-free; Long service life and convenient maintenance.

- Beater: The purpose of a beater is to make pulp by crushing organic matter, which is beneficial for subsequent cooking and processing of feed or compost, thereby improving oil yield.

- Heating and stirring tank: After beating the pulp, the material is transported by a conveying pump to the heating and stirring tank for full steaming, and the waste oil is boiled out. The purpose is to improve the recovery rate of waste oil, reduce the oil content of waste residue, and increase the economic benefits of the enterprise; During high-temperature cooking, harmful bacteria can also be killed.

- Three phase separator: solves the problem of equipment blockage, poor slag discharge, and unclear oil and water due to the complex characteristics of kitchen waste residue, hardness, and fast wear and tear, and has a good separation effect.

Finally, the wastewater flows into the sewage tank, and the oil enters the storage tank to be converted into biodiesel. The solid residue can be transported away to be converted into feed or fertilizer, achieving the recycling of kitchen waste.