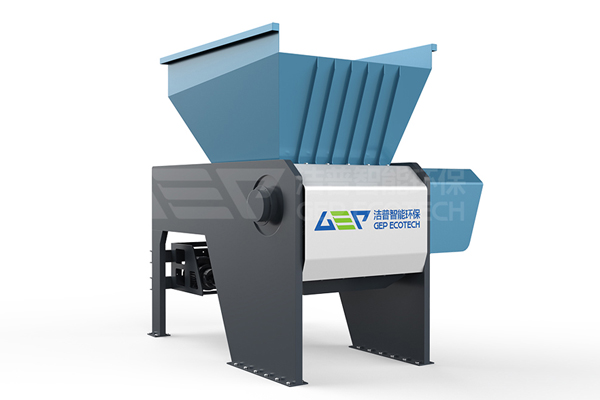

There are a lot of single shaft shredders in the market, such as crushing plastic, domestic waste, industrial waste, waste clothes, etc. GEP ECOTECH comprehensive single-shaft fine shredder has a strong market share, high efficiency, adjustable screen, strong material applicability and small discharge particle size. Here, we will introduce the advantages of GEP and its single shaft shredder.

The production strength of the manufacturer is very important. The guarantee in the process of reprocessing production and the guarantee of later service are more important. At present, GEP has more than 7000 square meters of domestic processing workshops, with 1-11 meters of various large-scale CNC machining centers and other perfect machining equipment, including more than 100 sets of main machining equipment, to complete the production and processing of all core parts, with advanced heat treatment , spraying and 6S management provide guarantee for high precision processing and mass production of crushing equipment.

Advantages of single-shaft fine shredder

GI patented intelligent technology, remote monitoring and diagnosis

GI intelligent technology is used to control and monitor the whole production process in real time, real-time on-line running state monitoring and centralized control, and the running data are provided to the central control center in time.

Imported bearing, multi-combined seals

Imported bearings and multiple combined seals are adopted, which have high load resistance, long service life, dust-proof, waterproof and pollution-proof, and ensure the continuous and stable operation of the machine.

Hydraulic auxiliary structure, easy maintenance

The swing arm hydraulic pressure device can push the material smoothly and effectively to the shredding area; the hydraulic opened repair door, the hydraulic opened screen with one key opening, greatly facilitating the replacement, maintenance and maintenance of the cutter and screen.

Screen can be replaced independently reduced maintenance costs

The whole set of screen is composed of several separated screens parts, each of which can be replaced independently, thus effectively reducing maintenance costs.

Independent movable cutters can be disassembled and installed independently

Each fixed cutter can be disassembled and installed independently, and can be quickly disassembled in a short time, which greatly reduces the workload of workers and improves the continuity of production.