After seeing our kitchen waste recycling system, biomass recycling system and RDF fuel preparation system, a customer expressed great interest and asked us whether kitchen waste could also be made into biomass Pellet fuel? The answer is yes, of course, there must be a reasonable process design. No more nonsense, go straight to the process:

Sorting and impurity removal → Mechanical crushing → Solid-liquid separation → Solid phase pulping → Three-phase separation → High temperature drying → Fine crushing → Material conveying → Pelletizing → Biomass pellet fuel

Sorting and impurity removal: Kitchen waste collected by specialized vehicles is measured and discharged into the material collection device. It is manually sorted and mechanically removed before entering the crushing process.

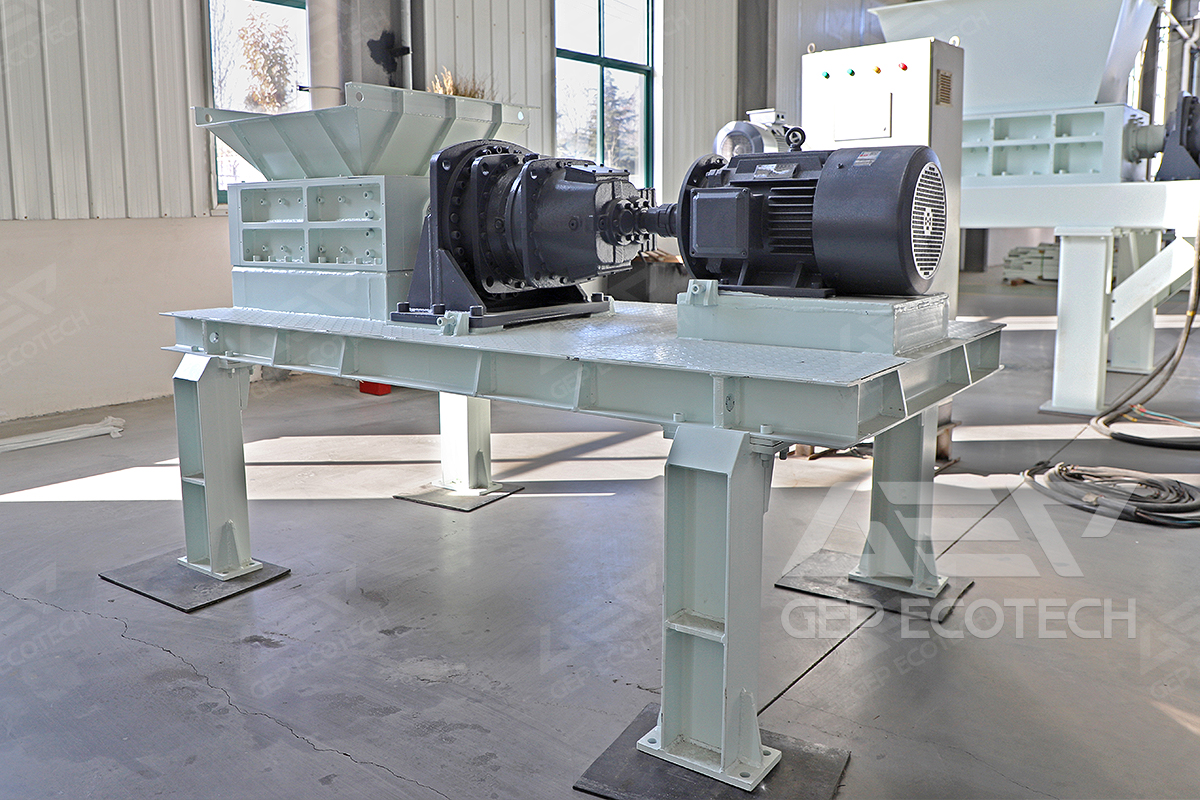

Mechanical crushing: Kitchen waste has complex components and diverse forms, so a dedicated GDF series kitchen waste crusher is required for crushing to produce materials with relatively uniform specifications. This crusher is wear-resistant, corrosion-resistant, with multiple waterproof and oil-resistant measures, not limited by oil and water. Moreover, the special knife has strong shear and tearing force, which is very effective in crushing kitchen waste such as fruits and vegetables, minced meat soup, plastic tissue, etc.

Solid-liquid separation: Use a screw press dewatering machine to perform primary solid-liquid separation of the material. The liquid phase enters the oil-water separation facility, and the solid phase enters the pulping process for pulping.

Solid phase pulping: By high-speed stirring, a solid substance containing a certain amount of water and oil is formed into a slurry like substance.

Three-phase separation: The solid substance after pulping enters the three-phase separator. After solid-oil water separation, the solid substance enters the subsequent drying and granulation process, and the oil and water are respectively sent to the oil storage tank and the wastewater pretreatment system.

High temperature drying: Drying solid substances to form solid raw materials and high-temperature gases to be treated.

Fine crushing: Use a dedicated fine crusher to finely crush the dried solid material, obtaining smaller particle sizes. It is recommended to use the third-generation European version of the fine crusher, which has strong crushing capacity, wide application range, convenient maintenance, long service life, and eye-catching comprehensive performance.

Material conveying: This system requires corresponding conveying equipment for material conveying, such as shaftless screw conveyors, belt conveyors, and even material boxes.

Pelletizing: Biomass pellet molding is the key of the whole system. We use a special molding machine to produce biomass Pellet fuel with high calorific value, small particle size, easy combustion and transportation, which can be used for biomass power generation, cement kiln blending and energy utilization of incineration plants.

The process design of this system is reasonable and standardized, with guaranteed equipment quality, safety and reliability, high feasibility, and environmental protection standards. It comprehensively utilizes waste resources to produce renewable energy, in line with the national policy of developing circular economy and building a conservation-oriented society.

Whether garbage is grass or treasure depends on whether you can handle it properly. Find GEP for garbage disposal, turning waste into treasure is very reliable!