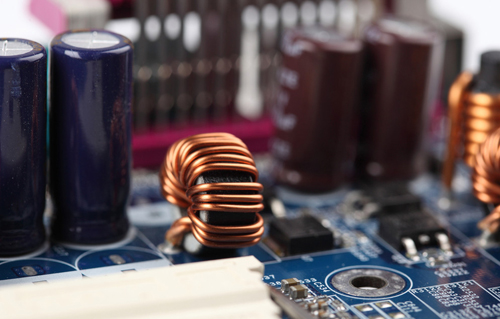

With the electronic products coming into people's life, China has become the largest consumer of electronic products. At the same time, a large number of electronic waste has been produced. E-waste contains a large number of harmful heavy metals, improper disposal of garbage, it will cause serious harm to the atmosphere, water and soil environment. At the same time, electronic waste is also rich in gold, silver, copper and other precious metals, improper handling is also a great waste of resources. So, how do we deal with e-waste?

Classification, recycling and disassembly

The classification, recovery and disassembly of electronic waste usually refers to the dismantling of electronic waste into various fragments after disassembly. In Sweden Stehman technology center, electronic waste are roughly divided into five parts: the large metal parts, PCBs, packaging materials, plastic parts and a cathode ray tube, and then further split into 70 different fragments. In the process of disassembly, the memory chip and the integrated circuit board can be repaired or upgraded, and the life of the utility model can be prolonged and used. The parts containing harmful substances can be separately processed by the reliability test.

Recovery of metals from waste

The recycling process of metals in electronic waste is complex, usually by separating metals from impurities at high temperatures, and refining metals by several corresponding processes. The precious metals, such as copper, gold, silver, platinum and palladium, are usually recovered by converter process.

The recycling process is: melting, refining, and electrolysis.

Melt

After sampling, different electronic wastes are uniformly mixed and added to the furnace as raw material. The top layer of molten electronic waste is slag, and the bottom is copper. Copper and a little slag go into the converter, and the remaining slag and ore are recovered by flotation to recover some precious metals. Finally, the remaining slag is piled up in the residue, which can be further concentrated and refined to recover the noble metal.

Refine

From the furnace of copper added to the converter in mixed refining by oxygen in molten copper iron and sulfur, thereby purifying copper, and adding Portland slag formation. The upper slag mainly include iron and zinc; the lower layer is blister copper or copper nickel alloy. Through the further purification of the slag can be a byproduct of iron and zinc, and iron and zinc by iron and zinc slag processing furnace.

Electrolysis

The blister copper (98% copper) obtained from the converter is cast into the anode copper, which is called the anode casting. The formed anode copper contains 99% copper and 0.5% precious metal. The copper electrode is purified by electrolysis, using sulfuric acid and copper sulfate as the electrolyte. The direct current is about 20 thousand amperes in the process. Generally, 99.99% of pure copper can be obtained on the cathode plate, while the precious metal and impurities are left on the anode plate as an attachment of the anode and can be further refined.