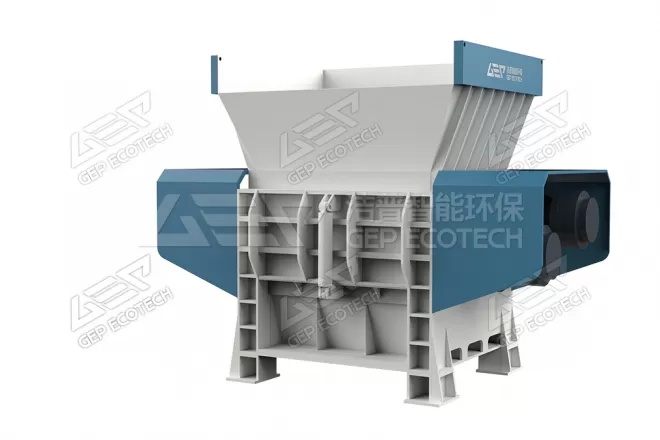

GDI Series Shredder is a multi-purpose dual-shaft shredder for reducing industrial and commercial wastes. It shreds various materials into optimum shapes and sizes for recycling, incineration, or landfill. GDI has unimaginable stability and is always reliable, which makes it possible to cope with the demand for waste disposal under the harshest working conditions.

Single Rotor Fine Shredder

ProductThe GSS series single rotor shredder is suitable for processing a wide range of materials to a small and uniform size, with a maximum capacity of around 1 - 20 tons per hour and a discharge size of 30 to 120 mm, depending on the model of the machine, the type of material, the size of the screen and the field of application.

Four-Shaft Shredder

ProductFour-Shaft shredder is a multi-purpose shredder. It has the same working principle as two-shaft shredder. GF Series four-shaft shredder can control the final material size by equipping a screen at the outlet. Four-shaft fine shredder provides greater shearing force than two-shaft shredder, it can handle all kinds of toughness, ductility of waste materials and obtain consistent shape and size.

Behind the prosperity of the local leather processing industry, waste materials such as waste leather and waste textiles have caused serious environmental pollution and become a focus of public attention. As a result, the government has consolidated and shut down hundreds of related enterprises, leading to a significant decline in annual output value. In order to solve the problem of industrial solid waste restricting economic development, the local government has launched a recycling project, striving for a win-win situation between economy and environmental protection. In this project, industrial solid waste is transported to the storage pit by garbage collection trucks, and then shredded to a size of 150-200mm by a double shaft shredder, and mixed with sludge for co-firing. Since the project started, the equipment has been in good condition and the size of the shredded materials meets the standard. This effectively alleviates the environmental problems caused by the leather processing industry and explores

Compared to coal powder, waste spinning has the advantages of high volatile matter, low ash content, low moisture content, and considerable calorific value (average around 4,300 kcal), and has good potential as a substitute fuel. GEP ECOTECH has tailored this fuel pretreatment solution for customers, covering processes such as three-stage double shaft shredder shredding, magnetic separator for iron removal, and baling machine for compression. In this scheme, specific design adjustments are made to the cutters of each stage of the double shaft shredder to gradually reduce the discharge size, ultimately meeting the size requirements for fuel entering the boiler, effectively improving the applicability and stability of textile waste as an alternative fuel in the cement production process. The customer stated that the production line ensures stable and high-quality fuel supply, meeting their demand for high-quality fuel.

All equipment of the project (double-shaft shredder, magnetic separator, chain plate conveyor, belt conveyor, intelligent control system and dust removal system) are purchased from GEP ECOTECH. The main treatment materials are bulky waste, such as sofas, mattresses, wooden furniture, etc. that are no longer used in the life of residents. After mechanical shredding, magnetic separation, manual disassembly and other treatments, bulky waste will be removed from high priced materials like metals, and teh rest materials will be sent to waste incineration plant for incineration. The customer said that since the introduction of the intelligent bulky waste shredding process from GEP ECOTECH, it has completely solved the problems of local bulky waste, such as disorderly stacking and difficult disposal, which has improved the local waste sorting classification treatment level.

As industries strive to address environmental challenges and enhance sustainability, converting waste into fuel has emerged as a significant solution. Industrial shredders play a pivotal role in this process by preparing waste materials for transformation into valuable energy sources. This article examines the function of industrial shredders in waste-to-fuel projects and explores the types of shredders commonly used in these applications.Role of Industrial Shredders in Waste-to-Fuel ProjectsIndustrial shredders are essential in waste-to-fuel projects for several reasons:Size Reduction: Shredders reduce the size of waste materials, making them easier to handle and process. This size reduction is crucial for ensuring that the material can be efficiently converted into fuel.Material Homogenization: By shredding waste into uniform pieces, shredders facilitate a consistent feedstock for further processing. This uniformity is vital for producing high-quality Refuse-Derived Fuel (RDF) or Solid Recovered Fuel (SRF

Recycling waste wood to provide fuel for biomass power plants has become very popular, which not only protects the environment, but also reduces waste of resources. The waste wood recycling process should be kept as streamlined as possible to provide fuel for power plants at a low cost per ton. Industrial shredders are the key equipment in this recycling process. Let's take a look at what processes are needed to recycle waste wood and convert it into biomass power plant fuel.ShreddingWaste wood is collected in large quantities and sent directly to the industrial shredder through conveying equipment. The dust suppression system on the biomass industrial shredder ensures that the wood processing does not produce dust that is normally generated in the air. The purpose here is to shred the material to the previously defined output size of 80 to 120 mm.Magnetic separation of metalsThe magnetic separator installed above the discharge conveyor can extract ferromagnetic parts such as nails, metal plates, hinges, etc

GEP Ecotech offers a complete line of industrial shredding equipment to handle various waste recycling or reduction requirement. All equipment is manufactured in Henan under strict quality control. The experience of design and the use of Canada and China cooperate technologies in the creation of our shredders makes it possible to offer high-quality and reliable equipment for work in various conditions. Our specialists provide technical support for the project from the moment of ordering to commissioning.GEP Ecotech Industrial Shredder RangesIn our catalog you can choose shredders of various capacities and configurations for shredding solid wastes. All shredder models have different performance characteristics, dimensions of the loading chamber and other indicators. When choosing a shredder, it is necessary to build on the type of the processed raw materials. Based on its quality properties, the selection of equipment is carried out.Double-Shaft ShredderDouble-shaft industrial shredder suitable for shredding

Heavy duty industrial shredders for metal are widely used in crushing scrap car shells, bicycle frames, motorcycle frames, scrap metal pipes, pipe fittings, scrap steel plates (thickness less than 7mm), iron sheets, aluminum alloys, engine shells, scrap aluminum castings, metal barrels, etc.The heavy duty industrial shredder for metal can effectively crush scrap metal to the finished size required by the customer. Different configurations can be replaced according to actual needs. The crushed materials can also be further processed into flakes or granules, which is environmentally friendly, economical and easy to transport.GD series double shaft shear shredder is an ideal heavy duty industrial shredder for metal,let us see what advantages it has:1.Integral knife box saves maintenance costs.2.Fixed knife independent detachable technology greatly reduces the workload of workers and improves the continuity of production.3.Intelligent system can monitor equipment operation anytime and anywhere.4.European

We recently supplied a high-performance industrial shredder to a major metal recycling company in Germany, designed specifically for shredding scrap iron. The equipment plays a pivotal role in the efficient processing of scrap metal, enabling the client to maximize their recycling capacity and improve their operations.Key Features of the 90kW Industrial Shredder for Scrap IronModel: GD10 Double-shaft shredderProcessing Capacity: 10-20 tons per hour (TPH)Output Size: around 100 mmPower: 2 x 90kWMotor: Siemens (Beide)Bearings: FAG, renowned for their durability under heavy industrial conditionsCutting System: High-strength D2 steel cutters for enhanced durability and sharpness, ideal for shredding tough scrap ironHydraulic System: Equipped with an 11kW hydraulic pushing system to ensure smooth material feed and continuous operationControl: Integrated with the GEP intelligent control and monitoring system, providing real-time performance feedback, diagnostics, and automated adjustmentsWhy Choose this Shredder

Industrial shredder machine for hard plastics uses the working principle of shearing, tearing and squeezing between knives to crush hard plastics of different sizes into small pieces of a certain size, saving storage and transportation space, and facilitating the recycling and processing of waste plastic materials into a variety of recycled products.GEP ECOTECH industrial shredder machine for hard plastics adopts imported crushing tools, which have corrosion resistance and impact resistance. At the same time, the bottom is equipped with a screen to make the output of less than 50mm at a time. We design crushing equipment and systems with different knife shapes, different torques, and different processes according to the proportion of various hard plastic wastes.Because plastic waste is difficult to degrade, landfill or incineration will cause "white pollution", which seriously harms water quality, soil, and atmospheric environment. Therefore, crushing and recycling is a good way to reduce the use of hard

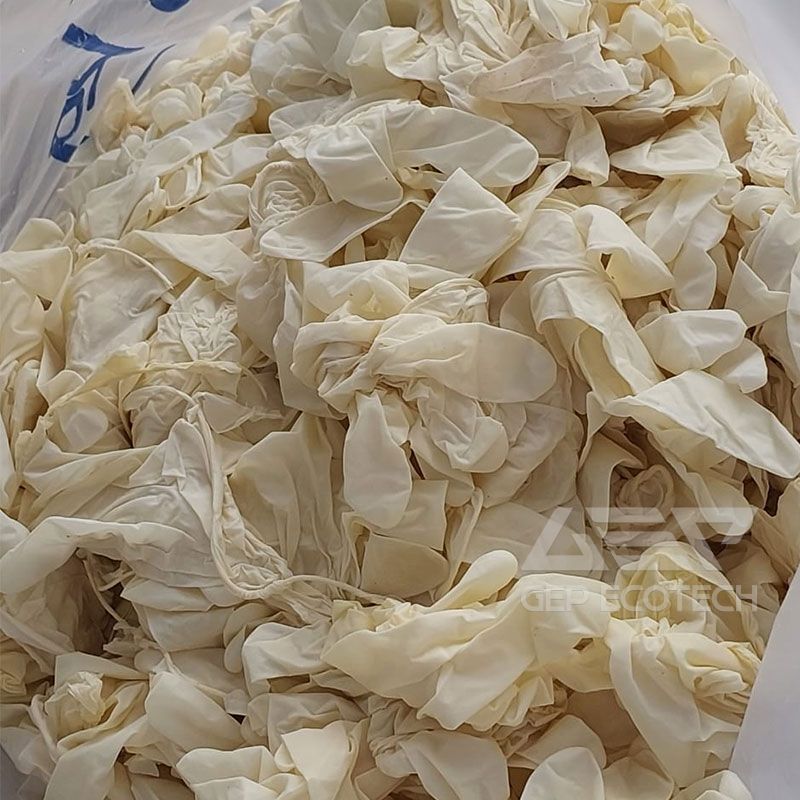

A large number of scrap gloves will be produced in industrial production, some of which are made of fabric and some are made of rubber. If these scrap gloves are directly incinerated or landfilled, it will be too wasteful. Waste fabric gloves contain a lot of fiber and organic matter, which can be used for incineration to generate electricity after crushing, and rubber gloves can be used to produce rubber particles after crushing. In the process of recycling used gloves, crushing is an unavoidable link, which requires an industrial shredder specially developed for used gloves.The scrap glove shredder that is mostly used now is a double-shaft industrial waste shredder, which uses the working principle of the interaction between the knives to process materials, and has a good shredding effect on soft and hard materials, and can easily shred a large amount of scrap gloves. The equipment is designed with low speed and high torque, which has the characteristics of large shearing force, good shredding effect, low

When investing in a hydraulic shredder, careful evaluation is essential to ensure it meets your operational requirements and provides long-term value. Here are the key factors to consider:1. Material Type and ApplicationMaterial Characteristics: Assess the type of materials you need to shred, such as metal, plastic, rubber, or mixed waste. High-density or abrasive materials may require specific shredder configurations.Application Area: Define the shredder's primary purpose (e.g., recycling, solid waste management, industrial processing) to choose a model suited to your needs.2. Capacity RequirementsThroughput: Determine the amount of material the shredder needs to process per hour. This will guide you in selecting a machine with the right capacity.Chamber Size: Ensure the shredder’s feed chamber is large enough to accommodate the size and volume of your materials.3. Power and Torque NeedsTorque Output: Hydraulic shredders are known for high torque output, essential for shredding tough or large materials.

R & D backgroundWaste refrigerators (including compression and electric absorption refrigerators and ice bucket cabinets) are one of the "waste electrical and electronic articles that should be recycled" advocated by the Environmental Protection Agency. Waste refrigerators are bulky in appearance and contain a variety of recyclable materials, such as iron, copper, aluminum, plastics, rubber, electronic parts, etc., most of which can be recycled and reused as renewable resources.The Gep mechanical waste refrigerator shredding and recycling line is mainly used to recover the refrigerators after the freon has been extracted and the compressors removed.Gep industrial shredder refrigerators recycling line equipments and details1) CE-certified double-shaft shredders etc. are used to crush the recycled refrigerators;double shaft shredderfour shaft shredder2) In the crushing stage, professional air separation equipment is used to process the defoaming film and dust removal;wind sifter3) Use specially designed

Industrial shredders have a wide range of uses and are suitable for crushing a variety of solid waste. There are many types of industrial shredders: According to their use, the industrial shredders can be divided into tire shredders, plastic shredders, household garbage shredders, kitchen waste shredders, metal shredders, electronic waste shredder, medical waste shredder, etc. According to the driving mode, there are electric motor drive and hydraulic motor drive. According to the structure, it can be divided into single shaft shredder, double shaft shearing shredder, four shaft shear shredder, etc.Here is a brief introduction to the GEP ECOTECH industrial shredders types commonly used on the market for your reference:GE series single shaft fine shredderGE series European version single shaft fine shredder is a new upgraded version of fine shredder, equipped with large capacity crushing bin, unique cutter design and high-efficiency pushing device, with strong medium and fine crushing capabilities, and

Industrial shredders that can be used for clothing typically fall into the category of "textile shredders." Textile shredders are designed specifically to process various types of textiles, including clothing, fabrics, and other textile waste. Here are some types of industrial shredders that can be used for clothing:Types of industrial shredders for clothingSingle Shaft Shredders: These shredders have a single rotating shaft equipped with sharp blades that cut and shred the clothing into smaller pieces. They are versatile and can handle a range of textile materials.Dual Shaft Shredders: These shredders have two counter-rotating shafts with interlocking blades that provide a more thorough and efficient shredding process. They are suitable for larger quantities of clothing waste.Quad Shaft Shredders: These advanced shredders have four shafts for even higher throughput and better shredding efficiency. They can handle a wide variety of textile materials, including thicker fabrics.When selecting an industrial

As a professional manufacturer of shredder, our shredder sold at home and abroad, many countries have on-site cased of shredders and production line. We have dozens of models, today we show you an industrial shredder GDI10 in Malaysia.GEP customized industrial shredderGDI10 is designed by manufactured by our company GEP. We design the chamber size, the main shaft torque, the thickness of cutter, the number of cutter tooth according to the capacity, input and output size, material features of this client. All of these provides our customer with stable and continuous operation.Induction of GDI10GDI 10 is a double-shaft shredder for crushing industrial waste. The capacity is around 10-15 tons per hour with 2*110KW motor power. GDI shredder is specialized for industrial waste.