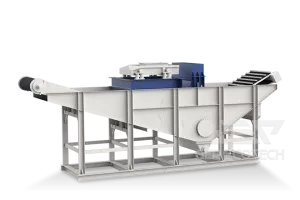

Pre-shredding machines are essential in the initial stage of wood pallet recycling, where large, bulky pallets need to be reduced to a more manageable size before further processing. A wood pallets pre-shredding machine is designed specifically for handling these tough, dense materials, providing efficient and reliable coarse shredding. This article highlights the key features of wood pallets pre-shredding machines, focusing on aspects such as throughput, output size, and operating modes.

High Throughput Capacity

Wood pallets pre-shredding machines are designed to handle high volumes of material, typically processing several tons per hour. The exact throughput can vary depending on the machine's size and power, but most models are capable of processing between 5 to 60 tons per hour. This high capacity ensures that even in large-scale operations, the machine can keep up with the demands of continuous shredding.

Coarse Output Size

The primary function of a pre-shredder is to break down large wood pallets into smaller, coarse pieces. The output size is typically larger and less uniform compared to fine shredding machines, with particle sizes often ranging from 100 mm to 400 mm. This coarse shredding stage is crucial for preparing the material for further processing, such as grinding or refining, where more precise and smaller particle sizes are required.

Robust Construction and Durability

Pre-shredding machines for wood pallets are built to withstand the heavy-duty nature of the task. They feature robust construction with wear-resistant components, such as hardened steel cutting blades and reinforced shafts. This durability ensures that the machine can handle the tough, dense nature of wood pallets, including nails and other contaminants, without frequent maintenance or downtime.

Operating Modes

Wood pallets pre-shredding machines often come with multiple operating modes to suit different processing needs. These modes may include:

- Continuous Mode: Ideal for high-volume operations where the machine runs continuously to process large amounts of material without interruption.

- Batch Mode: Suitable for smaller operations or specific tasks, where the machine processes a set amount of material before pausing.

- Automatic Mode: The machine automatically adjusts its operation based on the load, optimizing energy use and reducing wear on the components.

Energy Efficiency

Despite their heavy-duty capabilities, modern wood pallets pre-shredding machines are designed with energy efficiency in mind. Features such as intelligent load sensing and variable speed drives help to minimize energy consumption while maintaining high throughput levels. This not only reduces operational costs but also contributes to more sustainable processing practices.

A wood pallets pre-shredding machine is an essential tool for any operation dealing with large quantities of wood pallets. Its high throughput capacity, robust construction, and versatile operating modes make it ideal for preparing materials for further processing. By efficiently reducing the size of wood pallets, these machines play a critical role in the wood recycling process, contributing to both cost savings and environmental sustainability.