Putting the big blue bucket, paint bucket into the shredder, open conveying processes are not a few. For disposal companies, there are protective measures such as water spraying and fire extinguishers, and air purification measures such as fresh air systems, which have achieved safety and environmentally friendly production. However, one of our American customers has higher requirements for hazardous waste shredding and disposal, which is the newly designed product I am going to talk about today: intelligent building-type hazardous waste shredding system, also called hazardous waste building.

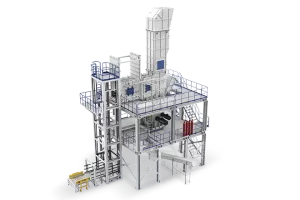

GEP ECOTECH's newly designed intelligent building-type hazardous waste shredding system includes lifting feeding system, cache device, closed crushing system, safe discharge system, active fire fighting facilities, passive fire fighting facilities, explosion-proof facilities, and specially designed rapid maintenance system. Multiple protection, layer by layer isolation and sealing operation, to ensure that the entire crushing process in a highly safe environment.

Dangerous solid waste such as paint drum and chemical drum is fed by the lifting system, wrapped in nitrogen in the cache area, and then sent to the sealed crushing system protected by nitrogen for crushing. After crushing, it is sent out through the discharge cache area. Under the protection of nitrogen in both the cache area and the crushing area, the entire crushing process is closed and safe, and can be observed and controlled by the intelligent monitoring system, providing great security for production and operation.

Even in very extreme cases caused by accidental explosion, the flame detector can also link the carbon dioxide fire extinguishing system to start in time to extinguish the flame. If the instantaneous detonation power is too large, the detonation device can also guide the energy release in the set direction to ensure the safety of the equipment and the surrounding environment. Multiple sealing and safety protection measures greatly reduce the risk of hazardous solid waste treatment operations, which can achieve safe production.

Like the dangerous waste building, the product design concept that can put production safety first may not be popular in a short time, but we hope to bring this awareness to everyone, perhaps in the near future, safety will become the basic prerequisite for all our production activities. As an enterprise focusing on solid waste disposal for more than ten years, GEP has been committed to the intelligence and automation of equipment, always put the user's production safety and operational benefits in front, and provide users with trustworthy products through continuous technological upgrading. If you have the intention of solid waste disposal, waste recycling, etc., please feel free to contact us and design a tailored production plan together.