Maximum Inclination Angles in the Design of Belt, Chain Plate, and Screw Conveyors

When designing bulk material handling systems, one critical factor that significantly affects the efficiency and feasibility of a conveyor is its maximum allowable inclination angle. The inclination angle directly impacts the type of conveyor that can be used, as well as the type of material being transported. Now let's explore the maximum conveying angles typically achievable for three common types of conveyors: belt conveyors, chain plate conveyors, and screw conveyors, and discuss the factors that influence these limits.

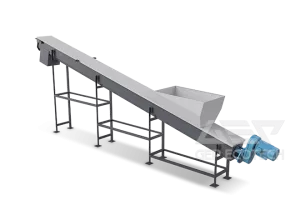

Belt Conveyors: Optimal for Gentle Inclines

Belt conveyors are widely used due to their simplicity, continuous transport capability, and versatility across industries. However, they have limitations in terms of steep inclines.

- Typical maximum inclination: 12° to 20°

- With special cleated or corrugated sidewall belts: up to 30° – 35°

- Key influencing factors:

- Material type (granular, powder, sticky)

- Belt surface (smooth vs. patterned)

- Belt speed and loading conditions

Applications: Logistics, mining, food processing, and packaging industries, especially where large volumes need to be transported over longer distances with minimal elevation change.

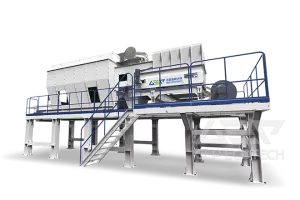

Chain Plate Conveyors: Robust and Steep-Capable

Chain plate (or slat) conveyors use fixed plates attached to chains to carry materials. They are durable, stable, and better suited for steeper angles and heavier or irregularly shaped items.

- Typical maximum inclination: 30° to 45°, depending on plate design and load type

- Advantages: Handles sharp inclines without material rollback; Suitable for high-temperature, oily, or heavy materials

- Commonly used in: Bottle/beverage industries, electronics manufacturing, automotive assembly, and waste handling

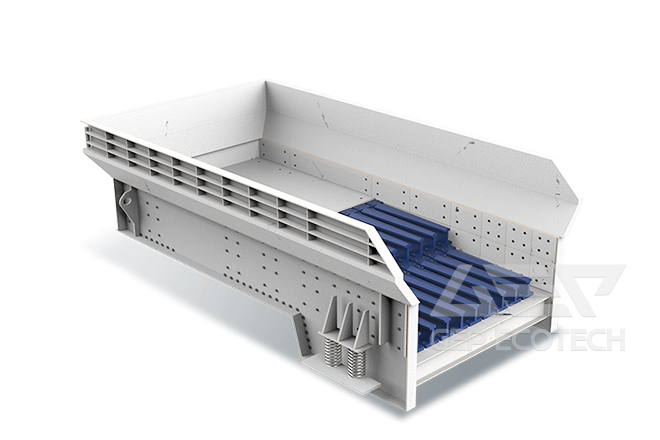

Screw Conveyors: Compact but Limited in Angle

Screw conveyors (augers) are ideal for enclosed conveying of semi-solid materials over short to medium distances. However, they are more sensitive to inclination due to gravity's effect on internal flow.

- Typical maximum inclination: Horizontal to 20° for standard designs; Up to 30° – 45° with customized pitch and trough modifications, but with reduced efficiency

- Material flow efficiency decreases significantly beyond 20°

- Ideal for: Sludge, food waste, powders, and granular materials in wastewater treatment, agriculture, and food production

Comparison Summary

| Conveyor Type | Max Inclination Angle | Best For | Notes |

|---|---|---|---|

| Belt Conveyor | 12°–20° (35° with cleats) | Bulk, dry materials | High-speed, long-distance |

| Chain Plate Conveyor | 30°–45° | Heavy, irregular loads | Durable and versatile |

| Screw Conveyor | Up to 20° (45° with efficiency loss) | Semi-solid or slow-flowing materials | Compact but angle-sensitive |

Choosing the right conveyor for an inclined transport application depends heavily on the angle of inclination, material properties, and operational environment. Belt conveyors offer speed and simplicity for gentle slopes; chain plate conveyors provide stability and high-angle performance; screw conveyors are compact and enclosed but limited in slope efficiency. Properly matching conveyor type to the application ensures optimal performance, reduced maintenance, and safer operation.