There is an increasing demand for the recycling and processing of wax in many industrial sectors, especially in candle making, cosmetics and other industrial applications. As a special material, the crushing process of board wax requires professional equipment to ensure processing efficiency and quality. This article is intended to provide professionals with a guide on how to select a suitable model of equipment for slab wax crushing.

Understand the processing needs of board wax

Before choosing crushing equipment, you first need to clarify the specific needs for wax processing:

- Material characteristics: Board wax has a certain softness, and different board waxes have different hardness and melting points, which will affect the selection of crushing equipment.

- Processing volume: The amount of wax to be processed will directly determine the size and processing capacity of the equipment required.

- Discharge particle size requirements: Select the appropriate shredder model and blade configuration according to the particle size required after the board wax is crushed.

Shredder Types Suitable for Board Wax

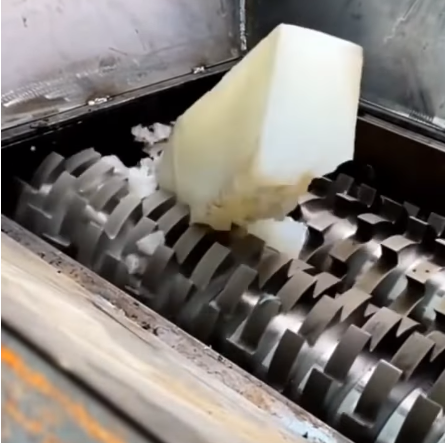

1.Low-speed and high-torque shredders: This type of shredder is very suitable for processing large amounts of wax and mixed materials because they generate less heat during the crushing process, which can prevent the wax from melting or adhering to the blades during processing. . This type of shredder can provide coarse crushing and has high durability.

2.Single-shaft shredder: suitable for application scenarios that have strict requirements on crushing particle size. The speed can be adjusted to adapt to board wax of different hardnesses. The output is finer and the output is lower than the speed and high torque shredder.

Choosing the right wax shredding equipment is crucial to improving processing efficiency, reducing costs and ensuring operational safety. By considering the key factors and features listed above, professionals can select the equipment model that suits their application needs, thereby supporting sustainable wax recycling and utilization. During the selection process, conducting adequate market research and communicating with manufacturers will help find a reliable, economical and practical shredding solution.