Relying on GEP ECOTECH's strong R&D and manufacturing capabilities and rich project operation experience, GEP ECOTECH's crushers have won widespread recognition in the market.

GEC Series Jaw Crusher

The jaw crusher is a primary crushing equipment for materials such as concrete blocks, crushed stones, bricks and tiles in construction waste. It uses movable and fixed jaw plates to compress, rub, and grind the incoming materials, achieving the crushing of the materials. After years of improvement, the jaw crusher has a simple structure, fewer components, high crushing ratio, and high bearing capacity, making it more suitable for crushing construction waste.

- Production capacity: 20-1000T/h

- Maximum feed particle size: 220-960mm

- Disposal of materials: mixed construction waste, waste concrete, waste bricks and tiles, waste asphalt, waste aerated blocks, aggregates, etc

GEF Series Impact Crusher

The impact and impact crushing principles of the impact crusher can ensure that materials naturally break along the texture and collide and rub with each other. The finished product is sturdy with few edges and corners, making it very suitable for making sand and gravel aggregates. The optimized design of the impact crusher has changed from two chambers to three chambers, with a larger feeding port and stronger crushing capacity. The addition of hydraulic maintenance system and auxiliary maintenance devices makes the equipment more convenient to use.

- Production capacity: 210-550T/h

- Maximum feed particle size: 500-700mm

- Disposal materials: mixed construction waste, decoration waste, waste bricks and tiles, waste asphalt, waste glass, waste aerated blocks, etc

GEY Series Hydraulic Cone Crusher

Hydraulic cone crusher integrates mechanical, hydraulic, electrical, automation, and intelligent control, responsible for hard materials such as medium and fine bricks, tiles, and stones. It adopts the principle of laminated crushing, which occurs between materials, resulting in high crushing efficiency, low wear of vulnerable parts, and low system production cost, which can meet the requirements of large-scale sand and gravel aggregate production lines.

- Production capacity: 55-700T/h

- Maximum feed particle size: 76-320mm

- Disposal materials: mixed construction waste, decoration waste, waste bricks and tiles, waste aerated blocks, etc

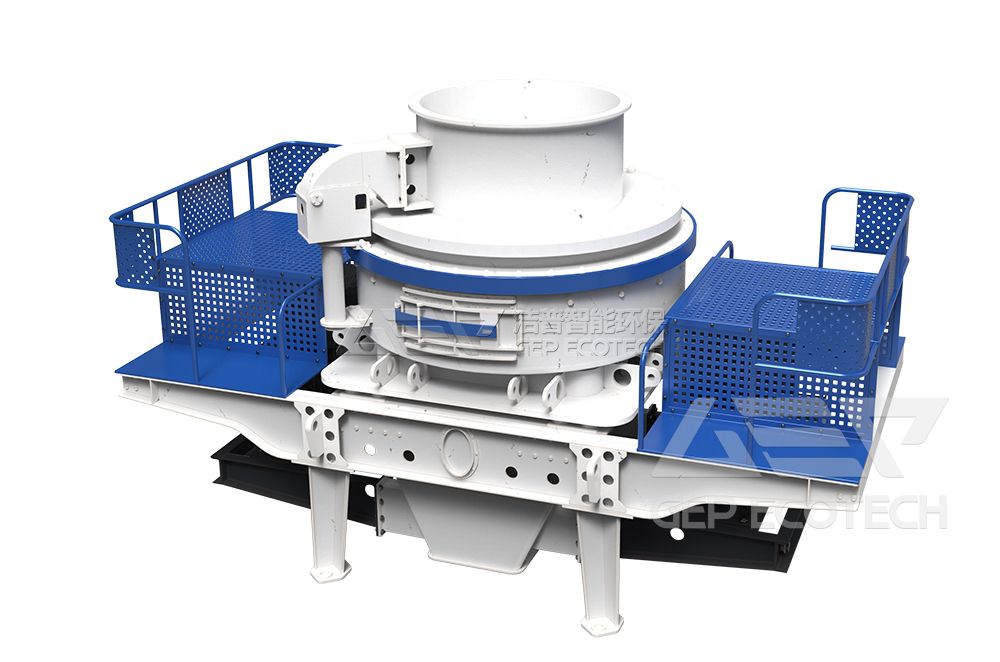

GEV Series Vertical Shaft Impact Crusher

Vertical shaft impact crusher, also known as sand making machine, imparts high-speed impact force to materials, forming mutual impact and friction between materials and lining plates, materials and materials, thereby achieving crushing effect. The equipment can crush hard materials such as concrete and waste bricks from construction and decoration waste to very small sizes, and the finished products are mostly cubic in shape. It is one of the main equipment for producing high-quality sand and stone materials.

- Production capacity: 30-600T/h

- Maximum feed particle size: 45 (70) -80 (150) mm

- Disposal materials: mixed construction waste, decoration waste, waste concrete, waste aerated blocks, etc

GEP ECOTECH's crushers handle a wide range of materials, ranging from coarse and medium to fine crushing. They are proficient in every sample, and can also be customized for special sizes. Parts are also a major brand. Welcome to inquire!