Bulky waste refers to the waste that weights more than 5Kg or volume greater than 0.2 cubic meters or length longer greater than 1 meter, and has strong integrity and needs to be disassembled for reuse treatment. Wood, sponge, metal and fabric are the main components of bulky waste, which has high recycling value.Therefore, reduced volume shredding and resource utilization are the only way to deal with bulky waste.

System composition

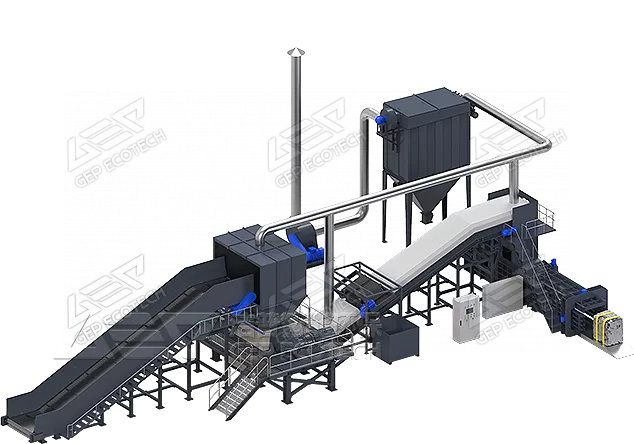

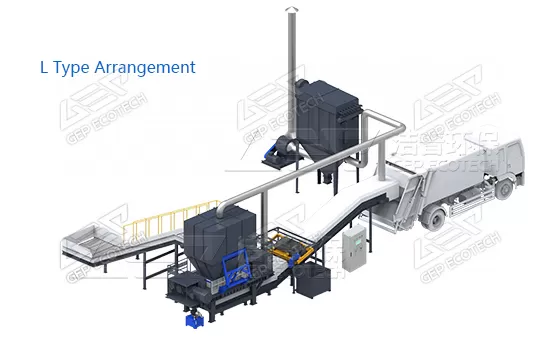

The disposal system of bulky waste is mainly composed of heavy chain conveyor, double shaft shearing shredder, iron separator, dust suppression system, intelligent control system and so on. Bulky waste is a kind of domestic garbage which is difficult to dispose. It is inconvenient to clear and transport, and the transportation cost is high. Conventional sanitation has not included this part in the collection and transportation system. In order to solve the problem of garbage siege, according to the characteristics of bulky waste, GEP has developed and designed an intelligent production line of bulky waste shredding and disposal system combined with mechanical, electrical, hydraulic and intelligent technology.

Process flow

Heavy chain conveyor or loader transports bulky waste to the shredding chamber. Double shaft shearing shredder crushes all kinds of mixed solid waste into smaller particles. In the shredding process, metal materials are automatically separated from other materials. Metal materials are automatically unloaded into the caching device by the iron separator. Other materials are transported to the garbage cleaning truck by the closed belt conveyor, and finally send it to the terminal disposal site by the truck, so as to realize rapid transit, effective volume reduction and reasonable classification of waste.

Features and advantages

- Safe and Efficient: Safety guard and warning signs are designed around the equipment. The feeding bin of bulky waste shredder adopts heightening or semi-enclosed design to prevent material splashing during shredding and ensure the safe operation of the equipment. Independent hydraulic system and hydraulic automatic pressing device realize automatic production and ensure the shredding efficiency and personnel safety.

- High-end Intelligent: The whole production line adopts GEP patented intelligent technology and Siemens PLC automatic control to realize intelligent detection, intelligent protection, intelligent maintenance and automatic weighing. It can predict and alarm equipment failure in advance, reduce the failure rate effectively, improve production continuity and reduce maintenance costs.

- Stable and Reliable: The core equipment of the large garbage crusher is the integral patent cutter box, high strength spindle, imported cutter, imported bearing, well-known brand motor and speed reducer, and exquisite and compact appearance design, which ensures the long-term stable operation of the equipment.

- Energy Conservation and Environmental Protection: Bulky waste is sent to the terminal disposal point directly through the transporter after the treatment of the production line, so that the garbage does not fall to the ground; equipped with professional dust suppression system system, targeted dust-removal for each dust point, high dust-removal efficiency, low energy consumption; and adopted fully closed design for the conveying equipment to avoid secondary pollution.