The rate of MSW generated every year is increasing. Therefore, it is an urgent task to seek a resource-based treatment approach for MSW. Converting MSW into refuse derived fuel, or RDF, is a relatively mature waste treatment method in developed countries. The United States, Europe, Japan, South Korea and other countries have widely used RDF fuel for power generation or heating.

How does MSW become RDF?

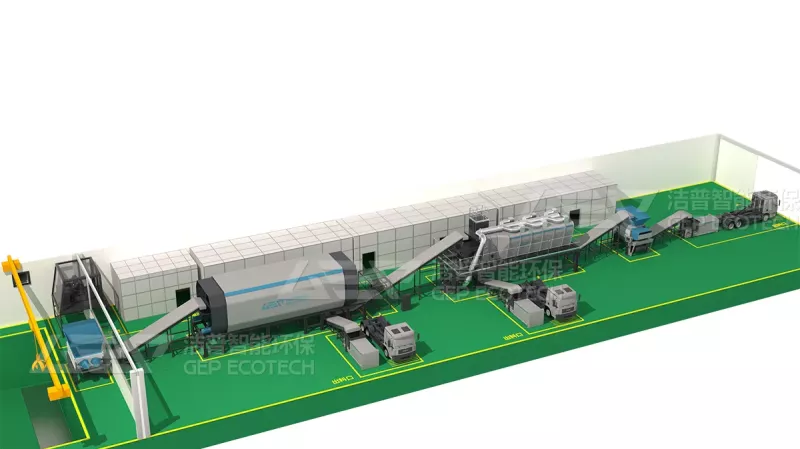

The production process of RDF fuel is to first classify the municipal solid waste with sorting equipment, and separate the recyclable parts according to different material properties. Combustible wastes such as plastics, waste paper, wood chips, and PVC are separated, and then crushed, dried, and ground to form granular fuels. The prepared RDF fuel is chalk-shaped, with a diameter of 15-20mm, a length of about 30-50mm, the moisture content is controlled below 12%, and the calorific value is close to that of coal. It can be widely used in waste-to-energy plants, cement plants, and various industrial boilers, etc.

What equipment will be used in the production of MSW to RDF?

As a solid waste pretreatment equipment provider that has been deeply involved in the solid waste pretreatment equipment industry for more than 10 years, GEP ECOTECH provides a complete set of mature and reliable RDF preparation systems and equipment around "MSW to RDF". Let's take a look at what equipment is used in the production of MSW to RDF?

- Magnetic separator

- Air sorter

- Magnetic separator

- Screening equipment (roller screen, relaxation screen, etc.)

- Pre shredder

- Secondary shredder

- RDF forming machine

RDF has a calorific value of 14595-20016 kJ/kg, and there is a waste-derived fuel called RPF that can generate a higher calorific value. The full name is Refuse Paper and Plastic Fuel, which is a solid waste-derived fuel made of waste paper and waste plastic sorted from industrial waste and MSW as raw materials, and is made by shredding and molding. The calorific value ranges from 20900-41800 kJ/kg. If you want to know more about RDF/RPF production line, please contact us!