| Model | Maximum feeding particle size (mm) | Spindle speed (r/min) | Capacity (t/h) | Power (kW) | Dimension (mm) |

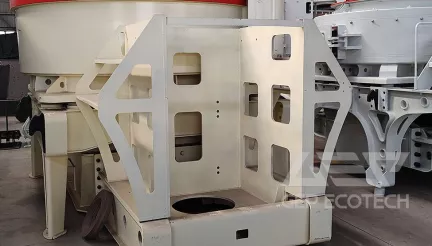

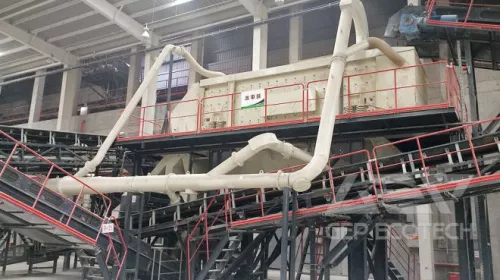

| GEV3000 | 45(70) | 1700-2000 | 30-60 | 75-90 | 3080×1716×2126 |

| GEV4000 | 55(70) | 1400-1620 | 50-90 | 110-150 | 4100×1916×2166 |

| GEV5000 | 65(80) | 1330-1530 | 80-150 | 180-264 | 4300×2215×2427 |

| GEV6000 | 70(100) | 1200-1400 | 120-250 | 264-320 | 5300×2728×2773 |

| GEV7000 | 70(100) | 1000-1200 | 180-350 | 320-400 | 5300×2728×2863 |

| GEV8000 | 80(150) | 1000-1100 | 250-380 | 400-440 | 6000×3000×3420 |

| GEV9000 | 80(150) | 1000-1100 | 380-600 | 440-630 | 6000×3022×3425 |

Note: Technical specifications may change without notice due to ongoing technological advancements.