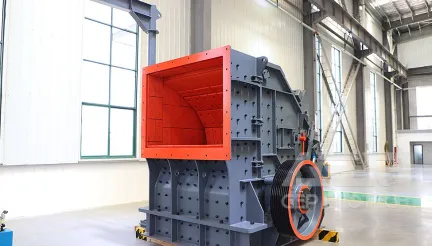

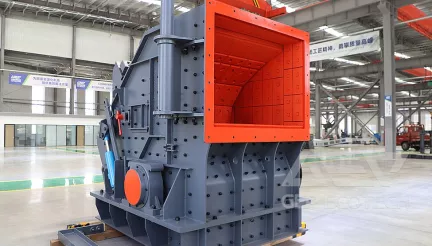

| Model | Rotor Size (mm) | Feeding port size (mm) | Maximum feeding particle size (mm) | Capacity (t/h) | Power (kW) | Weight (t) | |

| GEF615 | Φ1200x1400 | 1450x760 | 500 | 210-300 | 110-132 | 17.4 | |

| GEF715 | Φ1300x1500 | 1550x1070 | 600 | 300-460 | 200-250 | 26.0 | |

| GEF815 | Φ1400x1500 | 1550x1130 | 650 | 300-460 | 250-315 | 27.2 | |

| GEF915 | Φ1500x2000 | 2050x1060 | 700 | 350-550 | 400-500 | 36.2 | |

Note: Technical specifications may change without notice due to ongoing technological advancements.