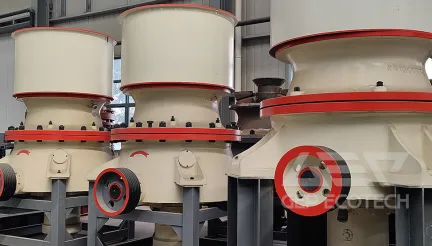

Single-Cylinder Cone Crusher

| Model | Cavity type | Max. feed size (mm) | Discharge port adjustment range (mm) | Capacity (t/h) | Power (kW) | Overall dimension (mm) |

| GED100 | Coarse type | 150 | 16-40 | 60-125 | 90 | 1700X1600X2650 |

| Medium type | 100 | 14-35 | 50-100 | |||

| Fine type | 60 | 10-30 | 40-90 | |||

| GED200 | Coarse type | 180 | 16-50 | 120-230 | 160 | 2100X1800X3100 |

| Medium type | 140 | 14-40 | 100-210 | |||

| Fine type | 70 | 10-30 | 80-180 | |||

| GED300 | Coarse type | 200 | 20-60 | 200-400 | 250 | 2600X2200X3800 |

| Medium type | 140 | 16-45 | 160-350 | |||

| Fine type | 90 | 12-35 | 130-280 | |||

| GED400 | Coarse type | 230 | 20-65 | 260-500 | 315 | 2800X2400X3900 |

| Medium type | 160 | 16-50 | 200-400 | |||

| Fine type | 100 | 12-40 | 160-350 | |||

| GED500 | Coarse type | 250 | 20-75 | 350-650 | 355 | 2800X2400X3900 |

| Medium type | 170 | 16-50 | 280-500 | |||

| Fine type | 100 | 12-40 | 200-450 | |||

| GED650 | Coarse type | 300 | 20-75 | 400-750 | 450 | 3160X2600X4250 |

| Medium type | 200 | 16-55 | 320-660 | |||

| Fine type | 120 | 12-45 | 280-500 | |||

| GED800 | Coarse type | 350 | 20-75 | 450-880 | 630 | 3350X2800X4450 |

| Medium type | 260 | 16-55 | 360-750 | |||

| Fine type | 160 | 12-45 | 300-690 |

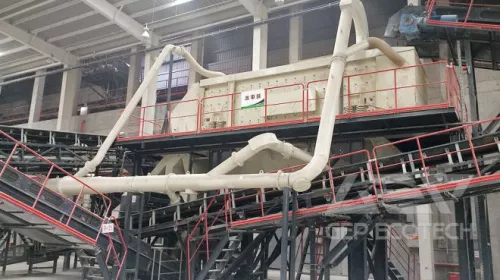

Double-Cylinder Cone Crusher

| Model | Cavity type | Max. feed size (mm) | Min. discharge opening size at closed edge (mm) | Capacity (t/h) | Power (kW) | Weight (t) |

| GEY160 | Coarse type | 150 | 13 | 120-240 | 160 | 13 |

| Fine type | 76 | 6 | 55-180 | |||

| GEY220 | Coarse type | 225 | 13 | 150-430 | 220 | 18 |

| Fine type | 86 | 6 | 90-260 | |||

| GEY315 | Coarse type | 290 | 13 | 190-610 | 315 | 26 |

| Fine type | 100 | 6 | 108-320 | |||

| GEY400 | Coarse type | 320 | 13 | 230-700 | 400 | 33 |

| Fine type | 120 | 6 | 140-370 |

Note: Technical specifications may change without notice due to ongoing technological advancements.