90kW Industrial Shredder for Scrap Iron in Germany

We recently supplied a high-performance industrial shredder to a major metal recycling company in Germany, designed specifically for shredding scrap iron. The equipment plays a pivotal role in the efficient processing of scrap metal, enabling the client to maximize their recycling capacity and improve their operations.Key Features of the 90kW Industrial Shredder for Scrap IronModel: GD10 Double-shaft shredderProcessing Capacity: 10-20 tons per hour (TPH)Output Size: around 100 mmPower: 2 x 90kWMotor:…

Learn MoreShredder for Waste Wood Contaminated with Iron

Waste wood contaminated with iron presents significant challenges in recycling and disposal processes. To effectively manage such materials, specialized shredders are essential. This article delves into the technology and applications of shredders designed specifically for waste wood contaminated with iron.Challenges of Iron-Contaminated Waste WoodWaste wood contaminated with iron poses several obstacles:Material Heterogeneity: The mixture of wood and iron creates a heterogeneous material that is difficult…

Learn MoreExploring Diverse Types of Scrap Iron Shredders for Efficient Metal Recycling

In the realm of metal recycling, the diversity of scrap iron demands a range of specialized shredding solutions. Scrap iron shredders, designed to handle different forms and sizes of iron scrap, play a pivotal role in optimizing metal recycling processes. This article explores various types of scrap iron shredders, each tailored to specific applications and iron waste streams.Single Shaft Iron ShreddersFeatures: Single shaft shredders are known for their simplicity and versatility. They feature a single…

Learn MoreAdvantages of Dry Crushing of Waste Iron Barrels

In life and production, iron barrels are usually used to store or transport various substances. Once the use is over, these waste iron barrels need to be disposed of. The dry crushing of waste iron barrels is to use a crushing mechanical equipment to break the iron barrels into smaller and uniform particles. Dry crushing of waste iron barrels is one of the common ways to deal with these waste iron barrels, which has the following advantages:High efficiency and energy saving: The dry crushing process of…

Learn MoreHazardous Waste Iron Buckets/Plastic Buckets Disposal Project in Zhejiang, China

The project is a general contracting project, and the scope of project includes the manufacture, packaging, transportation, loading and unloading, installation, commissioning, training and after-sales service. The disposal materials include not only iron buckets and plastic buckets (empty buckets, some materials with wall hanging materials), but also flexible materials such as rags, gloves, ton bags and woven bags. GEP's shredder can easily cut and crush a variety of materials of different materials. The…

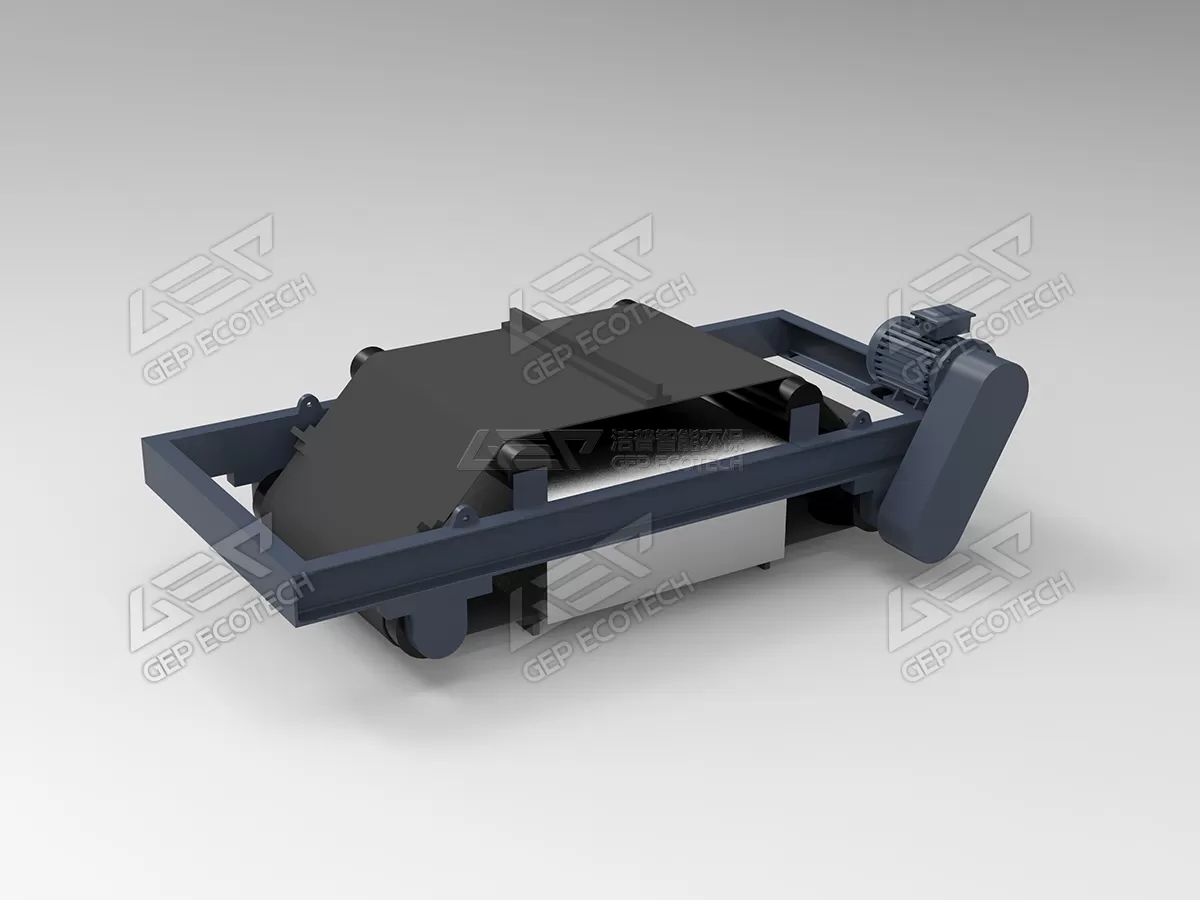

Learn MoreDouble shaft iron shredder

How is iron processed after recycling? People generally think that the recycling is done directly after processing, but in fact the process of reusing the iron after recycling is not so simple. This requires the use of our double-shaft shredder.Magnetic separation of iron recyclingFor solid waste after recycling, like metal cans of different materials, the method generally used is magnetic separation. Magnetic separation is a treatment method that uses the magnetic differences of various substances in…

Learn More