Construction Waste Crushing Project in Beijing, China

Capacity: 80-100 Ton/Hour

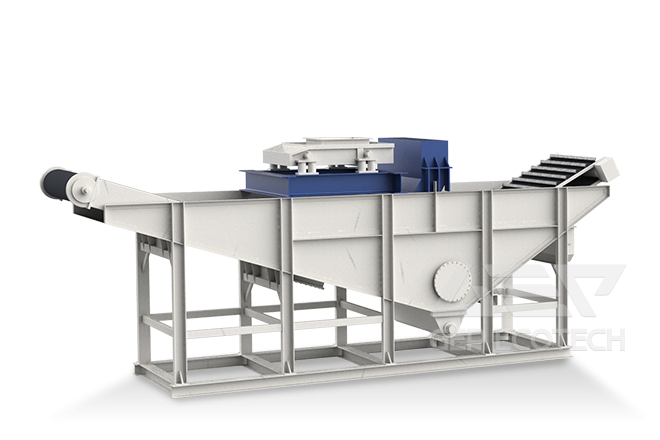

The GEW water flotation separator utilizes the principle that materials of different densities have different buoyancy in water, and separates light materials such as paper scraps, plastics, wood chips, and cloth strips from aggregates in construction waste. This machine adopts a modular design, which is easy to install, easy to maintain, highly automated, and has low power consumption. It can effectively remove sludge and debris from recycled aggregates, and improve the quality of recycled aggregates.

The water flotation separator consists of the bottom support assembly, box body, chain plate scraper, vibrating feeder, upper chute, lower chute, main belt conveyor, spiral sewage discharge machine, inlet pipeline, water connection device, maintenance platform, waterway system, etc. It is used for the separation of light materials from construction waste and demolition waste, and can also be used for the removal of sludge and impurities from sand and gravel aggregates, improving the quality of aggregates.

The material is uniformly dropped by the vibrating feeder, and then enters the box through the guide groove. The non floating heavy materials (aggregate) sink into the bottom of the equipment and is output to one side of the equipment through the belt conveyor; Mixed light materials such as plastic waste, wood waste, and paper waste float on the water surface and are output from the other side through the upper scraper; Sewage and sludge are automatically discharged through a spiral sewage discharge machine at the bottom after settling.

The distance between the scraper and the scraper groove is adjustable. When the scraper is worn, the gap between the groove and the scraper can be reduced to compensate for the amount of wear.

The discharge speed of the main belt is adjustable, and the output can be adjusted according to the customer’s requirements for the cleanliness of the finished products.

Equipped with a water level detection device, it can detect the water level in real time and automatically replenish water.

The underwater transmission part is made of nylon and stainless steel materials, which are not rusty and have self-lubricating properties.

Most components are connected by bolts, making installation, disassembly, and displacement convenient and reducing maintenance work.

Clean the aggregates while removing light materials, resulting in lower sludge content and a cleaner appearance in the finished products.

The feeding method is flexible, which can be arranged in a straight line with the feeding belt or at a right angle with the feeding belt.

The direction of light material discharge can be changed, and light materials can be discharged from different directions according to customer requirements.

Waste Tire Shredding & Recycling System

Construction & Demolition Waste Disposal System

Municipal Solid Waste Disposal System

Refuse-Derived Fuel & Solid Recovered Fuel System

Hazardous Waste Disposal System

Pre-Shredding System for Biomass Power Plant

Industrial & Commercial Solid Waste Disposal System

Send your inquiry for further information.

Find More Ways, Contact Us Today!

WhatsApp

WhatsApp

WeChat

WeChat