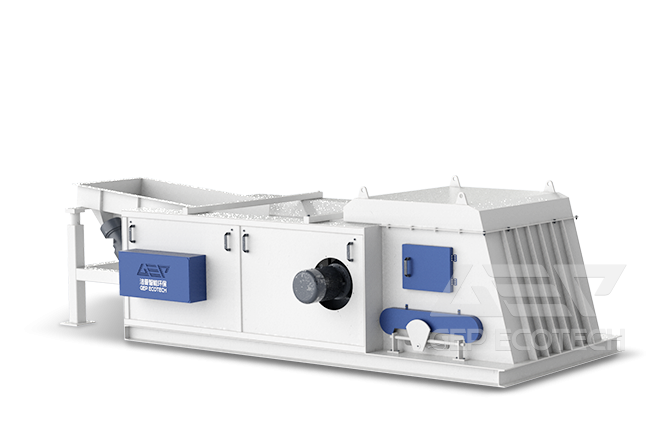

| Model | Feeding Belt | Energy Consumption | Weight | Overall Dimensions | |||||

| Feeding Width(mm) | FeedingLength(mm) | Feeding Size (mm2) | Capacity(m3/h) | Power(kW) | Weight(kg) | Length(mm) | Width(mm) | Height(mm) | |

| GES-5 | 500 | 1500 | ≤25 | 6 | 7 | 730 | 4600 | 1760 | 1110 |

| GES-6 | 600 | 10 | 895 | 1860 | |||||

| GES-6.5 | 650 | 15 | 950 | 1910 | |||||

| GES-8 | 810 | 20 | 1225 | 2060 | |||||

| GES-10 | 1015 | 25 | 1555 | 2260 | |||||

| GES-12 | 1215 | 30 | 1875 | 2460 | |||||

| GES-14 | 1400 | 1800 | 37 | 4000 | 2223 | ||||

| GES-16 | 1600 | 2000 | 40 | 2850 | 5100 | 2860 | |||

Note: Technical specifications may change without notice due to ongoing technological advancements.