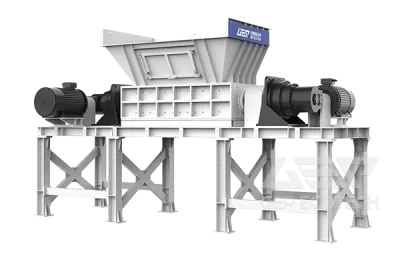

RDF is a fuel made from MSW, industrial or commercial waste by shredding, screening, wind separating, iron removal, drying, addition of chemicals and compression. RDF fuel has a high calorific value, stable combustion, easy transportation, easy storage, low secondary pollution and low dioxin emissions

Solid Recovery Fuel(SRF) is a fuel made from non-hazardous waste according to European EN 15359 for use in incineration plants or co-incineration facilities for the purpose of energy recovery and reuse.

RDF/SRF fuels are currently used primarily for electricity and heating, but can also be used as an alternative fuel for cement plants. The use of RDF/SRF fuels helps to reduce reliance on limited fossil fuels while reducing carbon emissions to meet tightening global environmental requirements.

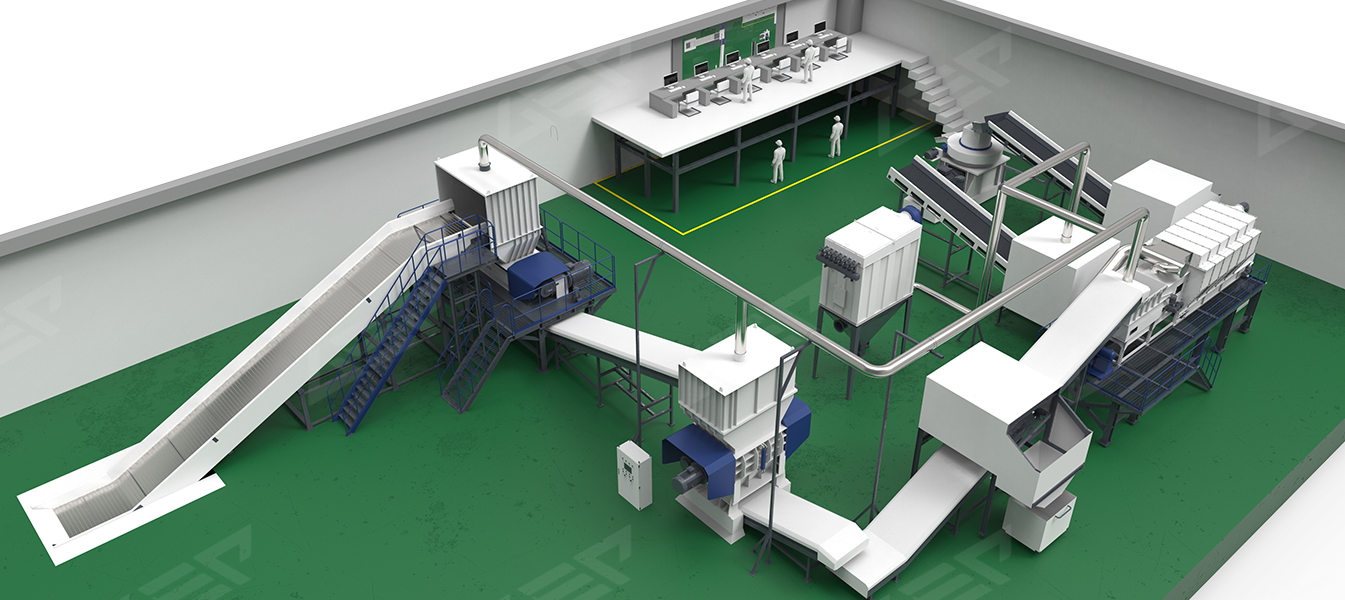

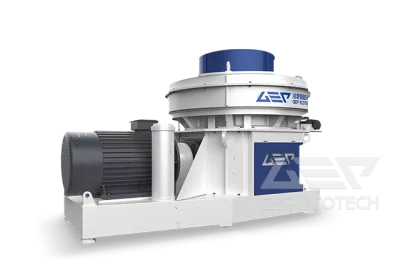

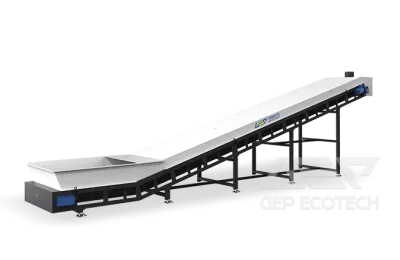

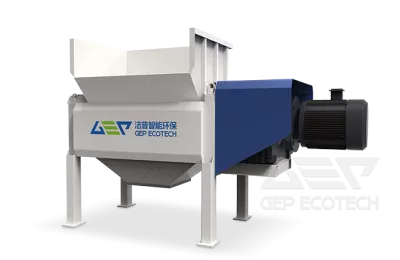

GEP ECOTECH is experienced in the field of RDF/SRF fuel preparation and can offer a comprehensive range of integrated disposal solutions. The equipment required for the system is stable and efficient, safe and reliable, with a low failure rate and low installed power, which significantly reduces system operating costs.