Commercial and industrial solid waste is the waste generated during industrial production or commercial activities. There are many different types of waste, including large quantities of waste paper products, waste plastics, rags and various textiles, waste rubber, broken leather products, waste wood and other high calorific value waste. The large amount of industrial and commercial solid waste generated takes up space and may contaminate the soil, groundwater or air and should be disposed of promptly. (Note that commercial and industrial solid waste under this section does not include hazardous and toxic waste, such as medical waste from hospitals, radioactive waste, etc.)

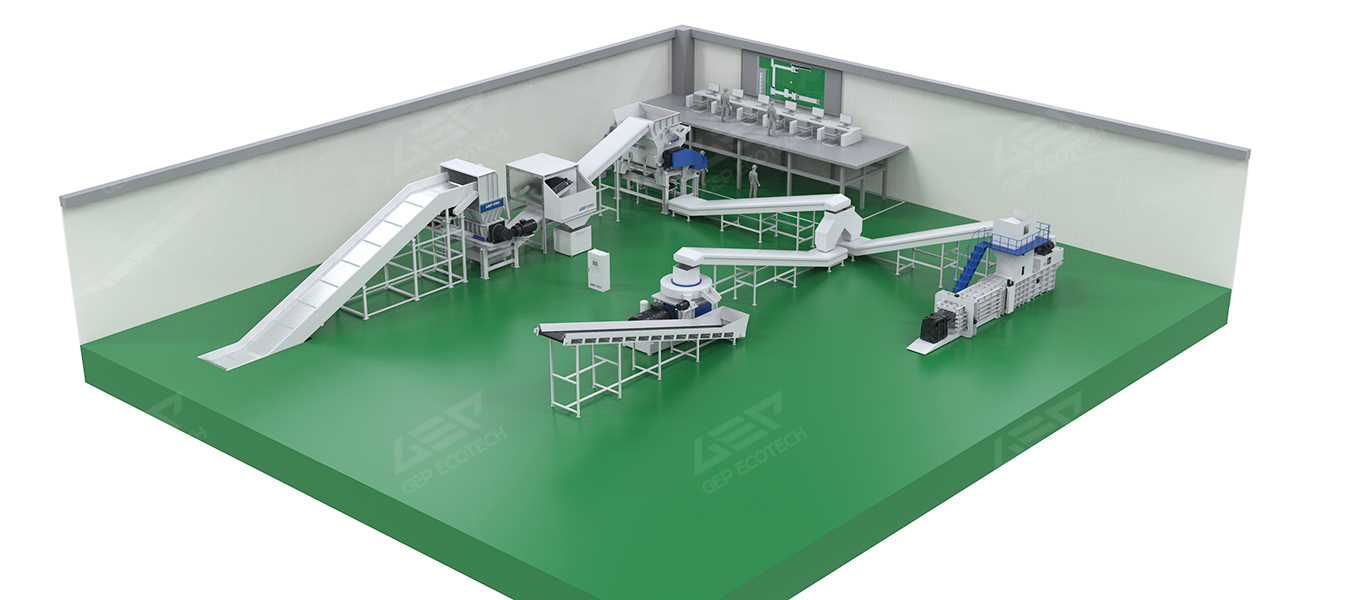

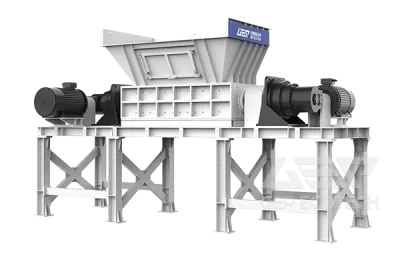

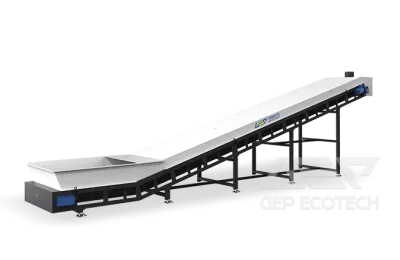

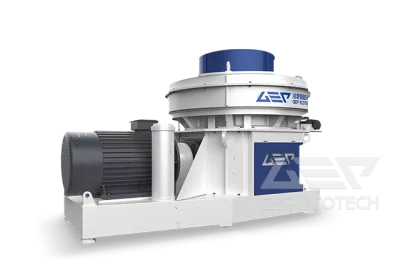

The disposal of commercial and industrial waste revolves around volume reduction, reuse and recycling. Depending on the characteristics of the material, a multi-stage shredder or crusher is used to reduce the volume of the material; separators such as an iron separator is used to separate the reusable metals such as iron, aluminum, copper and zinc; other materials can be recycled after separation, some high calorific value materials can also be produced as fuel and other worthless materials can be sent to landfill.

GEP ECOTECH offers integrated industrial solid waste disposal systems that are not only suitable for specialized solid waste disposal centres, but are also used by companies that generate large quantities of industrial solid waste. They have completely solved the problem of the large volume, complex composition and difficulty of disposal of industrial and commercial waste that exists worldwide.