Hazardous waste is waste that is corrosive, toxic, flammable, infectious, reactive and other that has harmful effects on human health or the environment, and whose harmful effects can even affect the sustainable development of society. Common hazardous wastes include paint drums, intermediate bulk containers (IBC tanks), chemical woven bags, batteries, expired pharmaceuticals, etc.

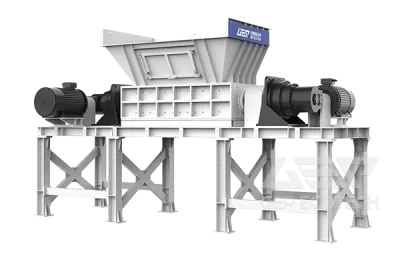

These "time bombs" cannot be simply shredded as they can burn, explode or cause gas/liquid leaks during the shredding process, so the hazardous waste disposal facility must be very safe and airtight.

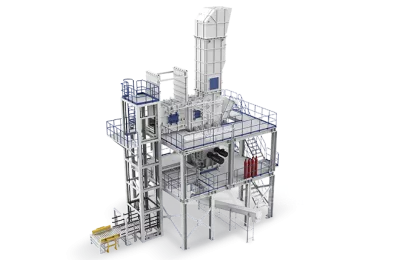

GEP ECOTECH's hazardous waste manangement machine meet international standards in terms of safety, stability, air tightness, ease of maintenance, user-friendliness of operation and life cycle, and can be used in cement kiln co-disposal, rotary kiln waste heat boiler disposal, battery shredding and recycling, industrial oil drums and paint drums shredding and recycling, etc.

GEP ECOTECH has extensive experience in providing shredding, fuel blending, destruction and recycling for the hazardous waste disposal industry. Whether you are recycling materials, disposing of them in a non-hazardous manner or burning them for energy, GEP ECOTECH can provide you with efficient, safe and stable solutions to help hazardous waste disposal companies improve their safety and economic value.