At this wonderful time when I am about to leave for my new job across the ocean, I feel that I need to be reintroduced to you all.

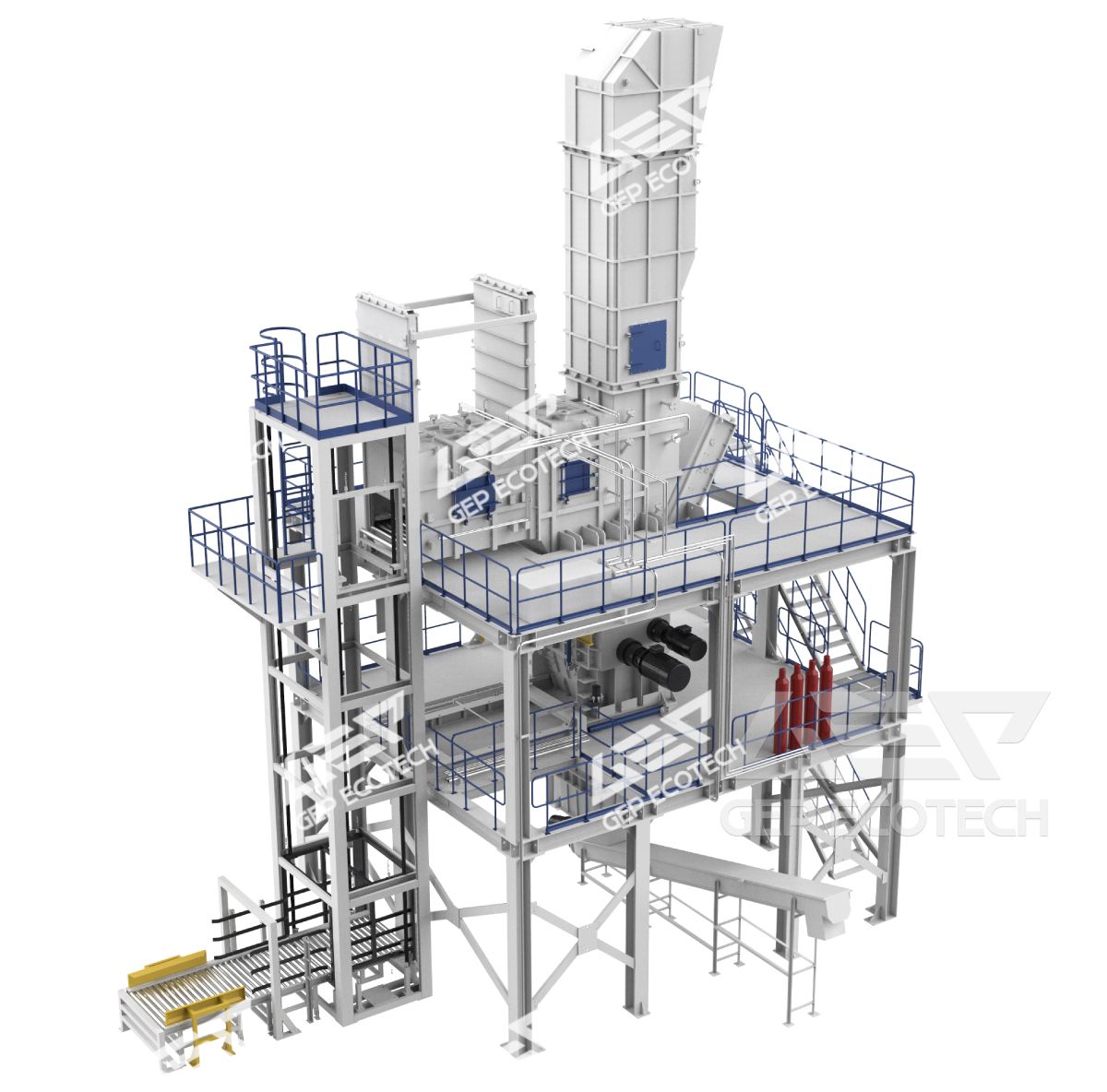

My scientific name is "Intelligent Tower Type Hazardous Waste Shredding System". Too long a name to remember? Then let's change it to the typical Chinese name "Hazardous Waste Building".

I was born because when shredding paint drums, chemical drums, paint buckets, chemical woven bags, oil sludge plastic bags and other hazardous waste, the risk of ignition and explosion could occur and a high-safety, high-capacity machine was urgently needed. This is how I was born in the equipment manufacturing base of GEP ECOTECH.

Tall and sturdy is the first impression I give. I am an all-rounder, as those who know me would say, because I am a combination of "fully automatic lifting feed system, feeding system, feeding system, shredding system, discharge system, fire protection system, maintenance system and intelligent monitoring system". The real feedback from those who have used me is that I am solid, reliable and secure - the proven and stable shredding system, the CO2 fire extinguishing system, the nitrogen protection system and the safety pressure relief system combine to create a fire protection system that deserves such a high rating.

One might wonder how I work with so many subsystems. In brief: Before the system is started, all gate valves are closed and nitrogen is injected into the system to reduce the oxygen concentration. The system is not started until the oxygen concentration has dropped to a set level. The lifting feed system lifts the material to the level of the sealed chamber, the front gate opens, the material enters the chamber, the front gate closes and the rear gate is closed at this point, then nitrogen is injected into the chamber. After the sealed chamber is filled with nitrogen to meet the requirements, the rear gate opens and the conveyor in the chamber feeds the material into the crushing chamber and the rear gate closes. The material is crushed in the crushing system with the aid of the feeding system. After crushing, the lower hopper gate valve opens and the material is discharged through the lower hopper. During the operation of the system, the oxygen content online monitoring system continuously monitors the oxygen concentration in the system and refills with nitrogen to meet the standard if necessary. In the event of fire, the intelligent monitoring system immediately alarms, the crushing system automatically stops, the front and rear gates of the sealing chamber (upper fire door) and the lower hopper gate valve (lower fire door) automatically close, isolating the flame from air contact in time to stop the spread of fire. At the same time, the carbon dioxide fire extinguishing system automatically turns on and releases the extinguishing agent to extinguish the fire.

Isn't it simple at all? Fortunately, I have a clever brain - intelligent monitoring system, which not only can control and monitor the operation status of all sub-systems online, comprehensive information to run the whole system automatically; but also has a key start/stop, abnormal alarm, emergency stop, overload protection and other functions, which can effectively reduce the failure rate of the system, while safeguarding the personal safety of the operator.

This is me, the intelligent and talented, MADE IN CHINA, intelligent Tower type hazardous waste shredding system that shines in the global hazardous waste disposal field!