Project Overview

As a key hazardous waste comprehensive disposal enterprise in Zhejiang Province, Taizhou Dechang Environmental Protection Co., Ltd. is mainly engaged in the collection, transportation, disposal of hazardous waste and investment and operation of environmental protection projects. In the process of hazardous waste disposal in the plant workshop, there are 25L iron drums, plastic drums, 200L iron drums (empty drums with wall hanging material) and flexible materials (rags, gloves, tonne bags, woven bags, etc.). The work of this project is to quickly pre-process the flexible materials from these hazardous wastes using crushing equipment.

Project Highlights

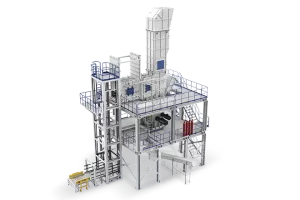

1. The disposal process of hazardous waste materials not only has certain safety risks, but also the hazardous waste materials themselves are complex and diverse, which has high requirements on the safety and quality of the equipment. The site uses a hazardous waste crushing plant (2t/h) with safety guards and a very high degree of automation in the production line, which only requires manual loading, ensuring the personal safety of the staff even in a dangerous working environment. The equipment has special treatment for core components such as cutter boxes and cutters, thus maintaining a stable and efficient working condition after it has been put into operation, guaranteeing the consistent production of the front and back parts of the hazardous waste disposal plant in the factory.

2. Considering that the residual material in the drum is prone to spillage during the feeding process, the receiving bin and the drop zone are specially designed to be sealed. In addition, for the problem that the round columnar empty drum equipment is not easy to eat material, it is equipped with a hydraulic press, which effectively prevents the material from slipping during the crushing process and improves the eating efficiency of the equipment.

3. The flexible materials in the hazardous waste shredder will wind up the shaft and fall unsmoothly due to the characteristics of the material itself, which will lead to equipment failure and unstable operation. Therefore, the equipment adopts the patented version of the anti-winding fixed knife, which fundamentally solves the problem of flexible material shredding and winding.

4. The project introduces the GI intelligent system, which strongly connects the data "islands" and equips the hazardous waste disposal production line with a "smart brain". The system achieves networked information transmission, personalised data reporting, intelligent data analysis, visualisation of production process control, real-time abnormal alarms and scientific production management and decision-making, helping users to accurately grasp equipment operating conditions in real time, greatly improving the operational efficiency of the production line and reducing operating costs.

Demonstration significance

1. From the perspective of the environmental protection industry, hazardous waste disposal has always been an industry with high safety requirements. As a well-known environmental protection enterprise in China, Dechang Environmental Protection has a significant position in the field of hazardous waste disposal in Zhejiang Province. The successful cooperation of this project has a high reference value and important demonstration significance for the promotion of hazardous waste remediation and treatment in Zhejiang Province. At the same time, as far as it is concerned, the operation of the hazardous waste production line has largely improved the hazardous waste disposal capacity of the plant and has accumulated a strength for the environmental protection industry.

2.From a production line operation point of view, the hazardous waste shredding and pre-treatment process is a crucial part of the process, so the disposal capacity, fit and continuity of the line are not to be ignored. The project was customized based on the preliminary project site survey and the specific operating conditions, so that the line's integrity and suitability can provide a practical reference for related design work.