According to Russian media reports, a fire broke out at the world's largest dump of discarded tires in Kuwait. The video shows rolling black smoke rising into the air, which can be seen from a long distance. Local media said that 52 million discarded tires are densely stacked in the dump, and the burning tires release carcinogenic compounds and heavy metals that can have serious effects on humans. If the fire is not stopped soon, it could cause a global ecological disaster.

The tire dump, located near the city of Sulaibiya in Kuwait, is said to cover 600,000 square meters and is the largest waste tire dump in the world. Kuwait's National Environmental Protection Agency has been deciding what to do with the old tires since November 2020, as they have been stored in this form for more than 30 years. Occasionally, fires break out and the country needs to put them out quickly.

Is there any other way out for used tires besides the pile? The answer is yes. Scrap tires are known as "black gold mine" and have a very high recycling value. For example, direct retreading and reuse, recycling steel wire to make steel, rubber grinding to make rubber powder, thermal cracking to refine oil, for cement rotary kiln or power station alternative fuel (TDF), etc.. Market data show that the recycled products of scrap tires after the process of crushing and grinding are more expensive than the directly recycled old tires.

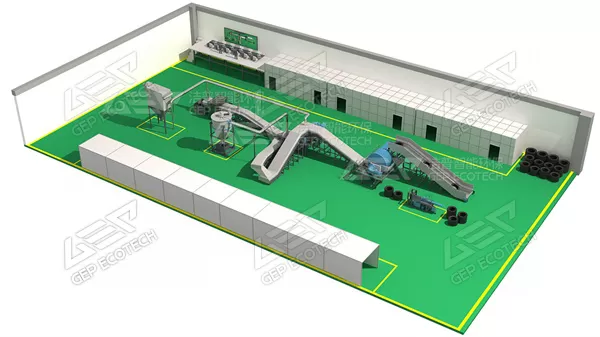

Gep Ecotech has been working in the field of waste tire disposal for many years and can provide a variety of waste tire recycling solutions.

(1) Shredding and grinding: The complete waste tires are shredded and ground by the shredding and grinding line to remove non-rubber impurities (nylon fiber, steel wire), so as to get a more pure rubber powder. According to the different particle size requirements of customers, it can be customized to grind into different mesh of tire powder.

(2) Cracking pretreatment: After being shredded into blocks and separated from steel wires, scrap tires are sent to a thermal cracking reactor to be made into fuel oil for use as fuel, combustible gas for power generation, and carbon black, which is more expensive in the market, respectively

(3) Making TDF: The calorific value of scrap tires reaches more than 8000 kcal, which is higher than coal-fired 5000 kcal. Many cement plants, power plants, steel plants and smelters have started to use crushed scrap tires as fuel, thus reducing energy consumption and production costs.

In addition to the above-mentioned solutions, which have been proven by many tire disposal companies, GEP can also provide various equipments required for tire disposal, such as tire shredder, tire wire extractor, steel wire separator, roller screen, rubber breaker, granulator, fiber separator and so on. Among them, the core equipment tire shredder adopts the structure design combining double shaft shredder and ring roller screen, which can screen while breaking to ensure the output and discharge size meet the production requirements.

Example Show